A Tale of Four Flats

If only flat making

was as easy as using the item pictured to the right here....

If only flat making

was as easy as using the item pictured to the right here....

If you've been through the telescope section of my web page, you've

probably read about our 30" F/3.8 scope. The primary is in good

shape, but

after using the scope a few times we discovered that the secondary

mirror (flat #1)

was introducing astigmatism. Mike Conron made the secondary - he

did

a wonderful job - he cored it from a 10" blank, ground and polished and

figured

it according to a borrowed reference flat (flat #2). The

astigmatism was

evidence

that the "reference flat" did not deserve to be called that (it wasn't

flat).

Recently, I bought a surplus 10" reference flat (flat #3). We

tested it

against several other surfaces, and confirmed that it was indeed quite

flat on BOTH sides, confirming the documentation that came with it.

I decided to refigure one 10" pyrex flat (flat #4) against my

reference

flat. Then I could use it for pressing to press a lap to work on

the 5.5" minor-axis diagonal mirror and fix it.

10" Pyrex Flat Refigure

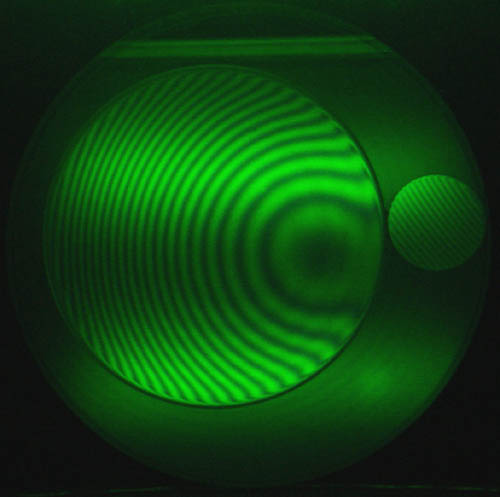

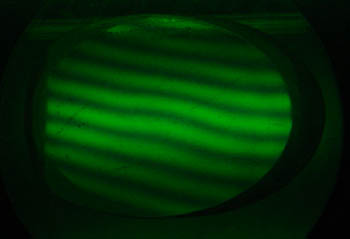

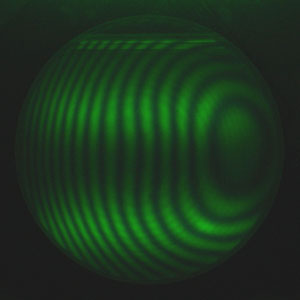

First, we checked the figure of the other "reference flat", which was

7" in

diameter and made of fused quartz. A photograph of it under test,

along

with a smaller 2" flat, sitting on my flat, is shown below on the left.

(The

2" flat had just been cleaned and handled, which is why its fringes

were

curved, due to thermal distortion.)

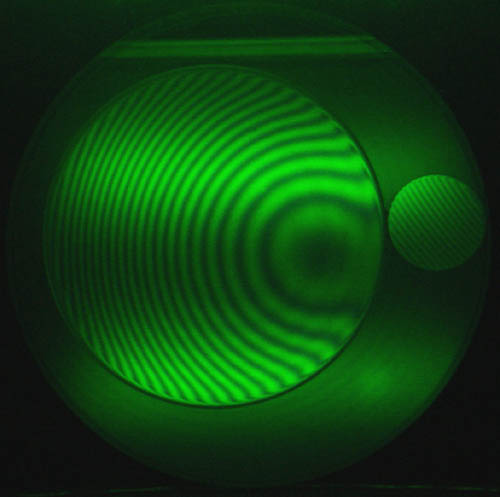

Additionally, a test of the 10" Pyrex mirror that was used in the

figuring of the diagonal revealed about 12 fringes of concavity (!),

pictured below at right (smaller photo). This 10" mirror mated

with the 6-7 fringe-convex 7" "reference flat", producing fairly

straight fringes. Unfortunately neither is flat.

These pieces were so far from flat that careful work with a modest

spherometer could easily show the deviation from a flat surface.

Here are the spherometer readings for my 10" reference flat, the 10"

Pyrex mirror (12 fringes concave) and another 10" surface that I

intended to use to grind against the Pyrex mirror to flatten it.

Note the needle centered on the 10 index in the first photo, and

reading 9.8 and 9.7 respectively in the next two photos. This

indicates concavity. (While the accuracy of the indicator is

admittedly not perfect, the relative readings were more consistent than

I expected.)

Due to the departure from flatness, I decided to go back to 12 micron

and grind the 10" Pyrex mirror flatter against another 10" Pyrex blank.

The

third surface, intended for grinding against the bad 10" Pyrex flat,

was

slightly more concave than the bad flat, as shown in the spherometer

readings

above. So, grinding the two together should make them both

reasonably

flat, and this of course could be adjusted during grinding to make them

both as flat as possible.

The picture below shows the polishing still remaining in the center of

the 10" Pyrex mirror surface after 20 minutes of grinding with 12

micron..

An hour gave a good uniform surface grind on both blanks, and then

about 45 minutes at 5 micron produced reasonably flat, ready to polish

surfaces. The positions of the pieces were adjusted to further

refine the flatness.

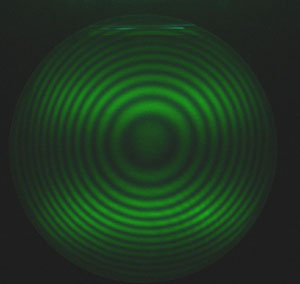

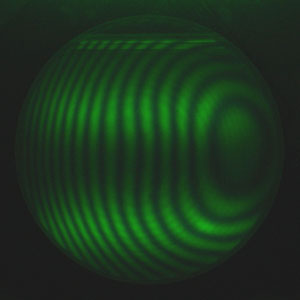

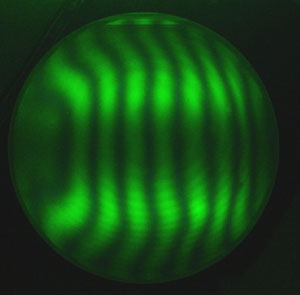

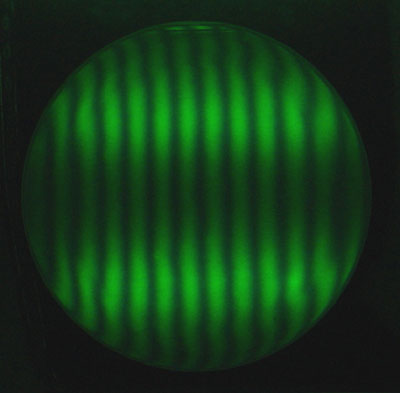

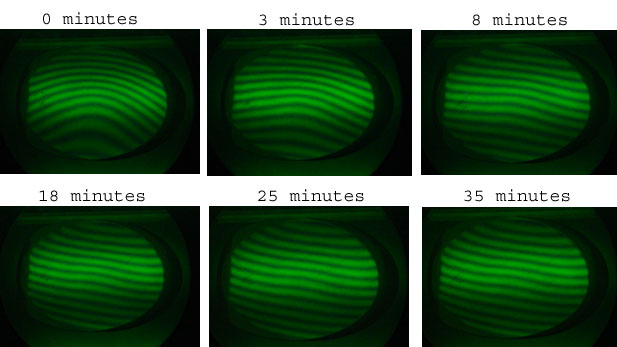

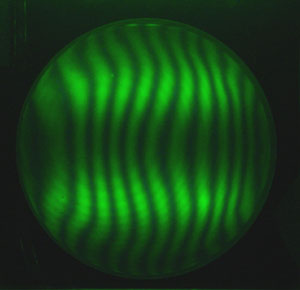

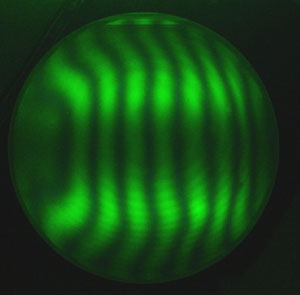

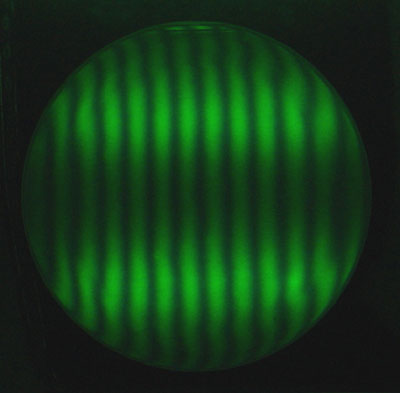

Below several pictures of the fringes at various stages in the

refiguring are shown. Polishing produced a somewhat concave 10"

mirror, and that was removed and the figure refined. At the end,

a fairly good 10"

flat was obtained, not perfect at the edge. Tool on top polishing

was used to remove the concavity, and the stubborn raised edge was

worked

down with a small local polisher and the full-sized lap. Lots of

pressing

is important in such work.

All in all, a successful refiguring. And now we have a good

surface to press a lap against for the refiguring of the 30" diagonal

mirror. (I

prefer not to press laps against nice reference flats that I have

purchased!)

Refiguring a 5.5" minor-axis secondary mirror

Careful work is required so that the edge of such an elliptical

secondary mirror is not turned. Pressing the lap on a known good

flat will help minimize this, and avoiding touching the edges

(especially on smaller flats) is advisable.

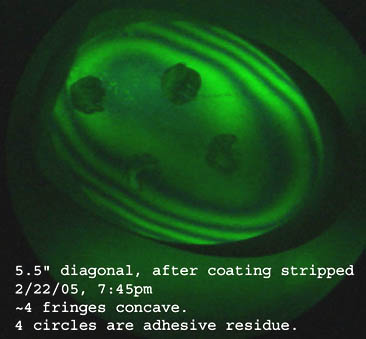

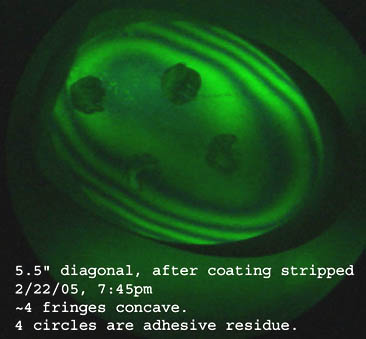

Here's a picture of the diagonal mirror before refiguring, under test

on my 10" reference flat. The mirror is approximately 4 fringes

concave, with many of the fringes bunched up at the edge, indicating a

severe slope error in the outer areas of the mirror. The picture

on the right is

of the mirror sitting on top of the 10" lap that was used to refigure

it.

(This lap was first used to make the 10" Pyrex flat described

above.)

Refiguring was accomplished by polishing the mirror on the lap with

strokes

of varying length and width. Care was taken not to heat up the

mirror

with heat from my hands, and pressure was kept light. Longer

strokes

lead to a more concave mirror, shorter to a more convex mirror, but

things

can act a little differently on the major and minor axes given the

strange

dimensions of the mirror.

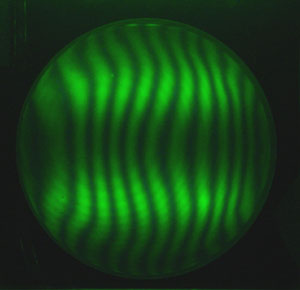

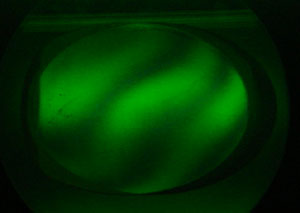

The concavity pictured above is astigmatic - the fringes follow the

elliptical

shape of the mirror. This shape gave way to overall convexity,

but

of the non-astigmatic type, with nice round fringes. From here,

the

mirror was gradually worked back to somewhat concave, and then flat

over

the course of about 10 figuring sessions.

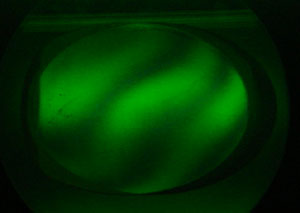

Here are pictures of the mirror and test setup in the midst of

refiguring,

and of a test where very few fringes are visible, and the test is quite

sensitive.

Both pictures show concavity in the center of the mirror.

The

test setup is my interference

tester

with a new light source - two 8-watt black lights (F8T5-BL - black

lights without the normal blue filters

on

the glass) shining through a green filter (Lee Filters - I'll check the

number) to isolate the 546 nm emission line. I like this setup -

the lights don't get hot, and I can leave it on for long periods of

time without cooking the ballasts or using much power.

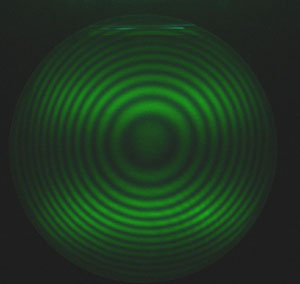

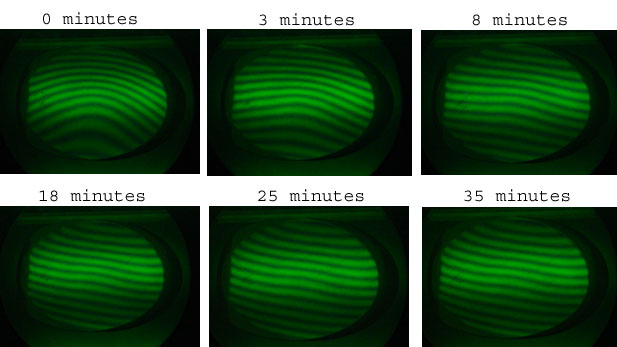

Testing this mirror revealed interesting cooling characteristics.

For

the scope (30" F/3.8) the cooling of a diagonal is nothing compared to

the

2.125" thick primary, but it's still interesting to watch. Below

is

a collection of six photos taken at various times after the mirror was

worked,

rinsed and dried. It appears the figure stabilizes fairly well

after

30 minutes. The figure goes from about two fringes of curvature

(1

wave on the glass) to less than 1/4 fringe (1/8th wave on the glass)

after

35 minutes. There is a slight depression in the center of the

mirror.

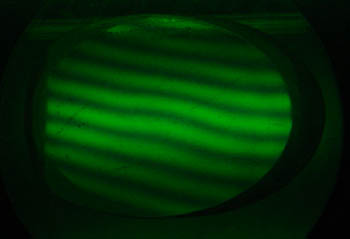

Here are the final fringe photos of the finished mirror. The

surface

is quite smooth. There is a very slight depression in the center,

but

I'm not going to risk the rest of the figure to remove it. It's a

whopping

1/10th wave deep. Can't wait to look at Jupiter and Saturn with

our

"new" scope!

After making the two flats this February and washing/drying my hands

countless

times, I will be using these:

Now it's time to finish the folding flat for my travel scope....

If only flat making

was as easy as using the item pictured to the right here....

If only flat making

was as easy as using the item pictured to the right here....