Mike's Mirror Making Musings

Copyright Michael

E. Lockwood, 2005-2007.

0.0 - Introduction, disclaimer, random info

This document is intended to help mirror makers take some of the

mystery out of figuring, and to make the process more tolerable.

After making

a good number of mirrors, some techniques float to the surface and

just

seem to work better. It is my goal to mention these here.

Some things just don't seem to work well. I'll try to

mention

those too.

The advice given is intended to help those working on mirrors

from 4" to 12" in diameter, with focal ratios between F/5 and F/8.

Faster or larger mirrors may require different techniques and

often

subdiameter

laps. Slower mirrors are ideally figured with very gentle

techniques

that remove glass very slowly, or they can be left spherical if that is

desired. Advice on topics other than figuring may be applicable

to mirrors that don't fall in the range given above.

DISCLAIMER:

There are many, many ways to make a mirror.

What I'm describing here is my particular flavor. There are

no absolutes in such a bizarre undertaking that involves making one of

the most precise surfaces ever crafted by a being on planet Earth.

I've taught mirror making classes, and these techniques worked

well there. The problem is there are so many variables involved

that each person will have to control a slightly different set,

depending on their work habits, environment, choice of materials and

how they work their hands and arms. So, to reduce the chances of

missing some critical bit of information, I

also expect that you've read at least two other pieces of literature on

mirror

making before you start relying on my instruction for making critical

figuring

decisions.

If you have any doubts about whether I'm right or not, remember one

thing - it's MY web page and I'm always right here! All

temperatures are

in degrees Fahrenheit, and all dimensions are in inches.

Edit 2019:

I commonly see people on online forums asking for advice.

They then receive advice from several (or more) people, and that

advice often conflicts with other advice, and the potential mirror

maker becomes confused. They are probably already confused

enough, and they don't need more confusion and indecision about how to

proceed.

So, my advice is as follows: Pick one mentor

and one method and learn all of its little tricks and finish your

project. If you want to learn another technique, do it on a

different mirror, or do it only after you and your mentor agree that

the original approach will not work for your project. Learning to

make a difficult mirror on an online forum is like trying to herd cats

remotely with a radio-controlled toy. (End Edit 2019)

Now for some instruction to make the art of figuring a bit easier and

hopefully faster, too. First I'll lay a bit of ground work on

fine

grinding, polishing, and lap pressing. Hopefully this will help

the reader get successfully

through polishing with a mirror that's more likely to be in a state

that's

ready for figuring.

0.1 - Fine Grinding

I recommend taking the time to fine-grind the backs of the mirror and

tool.

It will make polishing easier later on. What, you're

ignoring that previous statement?! DON'T!

If your mirror is at all thin for its size, grinding the back of the

mirror is just as important as grinding the front! If the back is

not flat, the mirror will warp during grinding and polishing, and you

will probably end up with ASTIGMATISM, and there is no reason for this,

other than carelessness. No matter how well you figure the

mirror, if it has significant astigmatism you will never be happy with

it, and it will not perform. Also, a smooth mirror back will

allow the mirror to slide around in the mirror cell more easily, which

makes it less likely to "hang up" and get stuck in certain

positions. This can affect performance by pinching the mirror,

and it can cause collimation to intermittently shift. A smooth

mirror back helps avoid these problems. It also looks better!

Grind the back of the mirror agains the back of the tool or against

something else (a piece of glass, or flat piece of metal) until you

don't see much difference from GOOD straight edge. Better yet,

use a good spherometer to check the curvature. Keep grinding the

back up through at least 12 micron, making sure it stays flat.

You don't have to grind as long as the optical surface, but try to

remove most of the pits of the previous grits.

Fine grinding is your last chance to get rid of pits from 220 grit (or

worse), which will NOT polish out before your run out of time,

patience,

and cerium oxide. My grinding sequence is typically 80, 120, 220,

320, and then I begin fine grinding with 25 micron. I HIGHLY

recommend

MicroGrit aluminum oxide - it's really good stuff. When you make

the transition from 220 or 320 carbo to 25 micron aluminum oxide, spend extra time at 25 micron and

make DAMN SURE that

no 220 or 320 pits remain. (You can use 40 micron instead of 25

micron,

or use 40 micron and then 25 micron.) There will always be some

larger pits, but

should

change locations after each wet or two. These come from the

subsurface cracks produced by grinding with carbo, and must be removed

with the aluminum oxide. Spend at least an hour

here

if this is your first mirror, preferably more. Use the time to

tweak

the sagitta and get the focal length closer to what you want.

I've

spent several hours on 25 micron, because sometimes 220 pits can take a

while

to remove.

Carbo and aluminum oxide are different materials with different

characteristics, after all. So, I check carefully for pits after

320 grit (looking for generation marks or 220 pits) and then do a

serious cleanup and grind with 25u for an extended period to remove

subsurface fractures until the grind looks excellent.

Alternatively one could use 500 grit, but I prefer to save a carbo

cleanup step and just run with 25u longer. This also gives time

to tweak the focal length a bit if necessary, and to get the blank nice

and spherical before moving on..

When using fine abrasives, take several teaspoons and put

it in a

squirt

bottle. Add about 8 ounces of water. The mixture should be

like

milk when shaken, containing a good amount of abrasive. Shake up

the

mixture, and squirt on a small puddle about the size of a quarter, and

gently

set the mirror on the tool. Watch the layer spread out between

the

two disks. Take a few gentle strokes. A little

water/abrasive

should ooze out the edges, but most should stay between the disks if

you've

used the right amount. Start working, but with fingertip pressure. In other words,

don't push down on the

top

disk - merely let the weight of the mirror or tool do the work.

(This

is your time to relax and rest your hands and arms before the labor of

polishing.) You'll start to hear

the

abrasive biting in after a minute or two - that's when the grinding

begins. Friction will be quite low. At this point, note if

there is any slip/grab tendency -

if there is, there is more asphericity than there should be or a

mismatch between the shape of the tool and mirror. Keep going,

but be gentle.

After 10-15 minutes of grinding

there

should be no bubble in the center (a sign that the tool and mirror do

not

mate

yet), and the surfaces should thus be in full contact. (If not,

go back to the previous abrasive and get it spherical.) Clean off

the

glass

"sludge" every 15 minutes or so. Add a little water if the

mixture gets too dry. You don't

need

too much abrasive - it doesn't wear out that quickly. You

will

need

less abrasive as you continue grinding, as the surfaces will mate

closer

and closer and you won't need as much to fill the gap.

The way I do it, fine grinding is a

much wetter process than coarse (carbo) grinding. With

MicroGrit, this method works very well, and the grind is quite

efficient. Drying out the grind is asking for nonsphericity, in

my experience. (If you have your own techniques that involve very

dry wets during fine grinding, that's fine, but I never do it that way.)

When there are no bubbles of

air trapped between the blanks, you're probably removing pits on all of

both

surfaces. You can verify this with the sharpie test - draw a grid

of lines such that they create approximately 1" squares on

the surface of the mirror. Then grind for a bit - ideally the

lines

will go away uniformly if you do a few minutes of MOT and then a few

minutes of TOT work (or TOT then MOT, it shouldn't matter). You

can usually go on to the next abrasive if the lines

have been worn away a couple of times, provided you don't find

abnormally large pits. Looks very carefully at the edge and

center of the blank with a loupe. Try to find pits that are

several times larger than the background small pits. If you find

these, chances a previous grit's grind wasn't quite complete. If

you find them only at the center or edge, then the radius of curvature

of the mirror has changed a bit since that larger grit was used, and

you should not start polishing until you're sure it is spherical.

After all big the pits from carbo are gone (and you've looked very hard

for

them!) due to 25u grinding,

I usually go to 12 micron, and then 5 micron. Each should take

1/2 to 1 hour if 25 micron was done correctly. Do more if

you

have any question in your mind about remaining pits. Use a 10X

power

eye loupe or magnifier to inspect the surface - it should be VERY

uniform in pit size over the entire surface of both disks, and free of

scratches. If you

finish 5 micron

MicroGrit with an excellent uniform grind and no scratches, polishing

will go much faster. Be gentle in all fine grinding, but be

very

gentle at the end of 5 micron. Add water only if you can get away

with

it during the last 15 minutes of 5 micron work. Keep the work

from

drying out or there may be contact problems. Use fingertip

pressure

to move the tool/mirror. A good 5 micron grind will ensure fast

polishing. If you know what you're doing, you can use 3

micron. I find that finishing with 3 micron abrasive speeds up

polishing over 5 micron. Just be careful and gentle with the

grinding.

A few last tips about fine grinding:

1) Near

the end of fine grinding, when using 9u or 5u, don't use too much ink

for the sharpie test. Opt for a thin line rather than a

wide line produced by some permanent markers. The ink itself can

affect the contact between the tool and mirror, so keep it to a

minimum. The lines should grind away quickly and uniformly.

Be especially concerned if the lines near the edge of the mirror have a

tendency to not go away as quickly as other areas of the mirror.

If you work both TOT and MOT and this happens, you need to looks for

pits, grind longer, and check your grinding stroke for the proper

length/technique. Redraw the sharpie lines and grind gently until

the lines near the edge of the mirorr disappear just as quickly as in

other areas. Then be grateful - you have just saved yourself many

hours of polishing!

2) Clean off the sludge for the last

5-10

minutes

of grinding with each fine grinding abrasive and randomize your

stoke a bit to help get as spherical as

possible before switching grits. This will help avoid grinding in

a low outer zone, which takes a LONG time to polish out (as mentioned

in hint 1). This is especially important for the last grit - you

want a sphere accurate to 1u at the end of 5u grinding, which you will

obtain automatically with proper technique.

0.11 Glass- and tool-specific

advice

- For grinding glass on glass (usually by hand), I often finish

with 3u and 1u, which leaves an incredible surface that polishes in

much less time than a surface finished with 5u. This can save a

lot of work if you ware working by hand. A nice 1u grind is a

beautiful thing to behold. This is not recommended for a first

mirror, as some fine grinding experience is recommended to make 3u and

1u work properly.

- For tile tools grinding pregenerated

Pyrex, I typically go with 320, 25u, 12u, 5u. I find that I often

get scratches with 3u with tile on Pyrex. If the generation is

really nicely done (typical for United Lens blanks) then I start with

320 and just grind for a bit longer to get rid of the generation

marks. For glass on pregenerated Pyrex, keep going with 3u and 1u

if you wish.

- For BVC ground with a tile tool, I stop at 9u. I find that

tile on BVC with 5u leads to scratches, even at slow grinding speeds.

- You can use finer abrasives with tile tools if you stone or bevel

the edges of the tiles to remove the sharp edge. I usually don't

bother.

0.2 - Pitch and Lap Tips

I use Cerox 1670 from Salem Distributing. It cuts fast and

leaves a fairly smooth surface. It can be used for figuring if

you use

a lot of water. However, refined Cerium products are better for

figuring -

they

leave a smoother surface, work slower (and therefore are easier to

control), but cost more. Other

ceriums

may work just as well as the one I recommended. (However, I have

heard

of several people having some scratching problems with Cerium from

Willmann-Bell, myself included.)

I recommend Gugolz 64 pitch for polishing at around 70 degrees

Fahrenheit for moderate F/ratio mirrors (F/5-F/7). For a

Texereau-style pitch hardness tester, G64 has a fall rate in the range

of 0.030" to 0.100" in five minutes (1 kg mass, point ground as

described by Texereau in an appendix).

At this hardness (for Gugolz 64), the pitch channels will close up in a

few hours of work. I have found that one of the best

indicators of the hardness of a pitch lap and how well it is working

with the operator's tecnhique is the time it takes the

channels in the lap to (nearly) close under normal hand

polishing conditions. For me, pitch that flows enough in 1

hour to nearly close the channels is quite soft (like Gugolz 55,

mentioned below), and a lap with channels that close up only after 10

or more hours is really hard. My preferred range for

work with a full-size lap is a channel closing time of 1.5 to 4 hours.

I like Gugolz 55 for subdiameter figuring laps at this temperature,

especially for use on mirrors faster

than F/5 (which I am not discussing here). G55 is also good for

polishing in the winter, when I'm cheap

and only heat the house up to 65 F. Figuring an F/4 mirror larger

than 8" with a full-sized lap requires using unconventional methods, so

I

use soft subdiameter laps for this. Subdiameter laps are a whole

other

animal, and I'm not covering their use in this document. The fall

rate for a Texereau-style tester is closer to 0.080" or 0.100"+ for

Gugolz 55.

Gugolz 73 works well for making optical flats because it's DAMN hard at

65-70 degrees. The channels close up quite slowly, in 10+ hours

of work. Sometimes they never seem to close!

Note - the hardness of pitch can vary depending on how old it is, how

it has been treated, and by who manufactured it and how well they

control the hardness in their manufacturing process. If you are

having figuring problems and suspect the pitch, I encourage you to take a few hours and build a simple pitch

tester - it will help you identify what hardness of pitch you

are working with.

0.21 - A few lap-making

thoughts:

I make my mid-size laps by cleaning the mirror and placing a layer of

tin foil over the mirror. Wrap a wall of masking tape around the

mirror, over the foil. Pour the pitch on the mirror. WARNING: if your mirror is plate glass,

this may cause the glass to crack if you haven't warmed it up gradually

to about the same temperature as the pitch!

After pouring, the

pitch should flow out to be at least 1/4" thick at the edge of the

mirror. I like a lap thickness between 1/4" and 3/8".

Thicker is fine too, but it requires more pitch. Before the

pitch cools

too much, set the tool on the pitch, making sure that one edge contacts

before the other. The tool will "float" on the pitch if it's not

too hot.

(If it is too hot, some pitch may be forced upward between the masking

tape and the tool.) Make sure the tool gets into contact with the

pitch over its entire surface - this may require you to press down the

tool into the pitch using your hands or weights. Once the tool is

in full contact with the pitch, remove any weight you have placed on

the tool. Let the pitch cool, remove the masking tape,

and slide the pitch

lap

off the mirror. (That operation may NOT be easy, but it will

eventually

slide off.)

Once the mirror and lap are separated, the foil should peel right off

the pitch. If it doesn't, run some cold water over it for a few

seconds and it will. Voila, we have a lap that will be in full

contact almost from the beginning, as long as there weren't too many

wrinkles in it. Channel it by your choice of methods.

0.3 - How to Press a Lap

My motto is "When it comes to pitch laps, contact is everything".

NOTHING will work as it should if you don't have contact.

Here's how I get it.

A warm press is done when a lap does not conform well to the mirror

(facets off by 1/16" or more in height), or when you are pressing a

very hard pitch lap. Warm pressing involves heating BOTH the lap

and mirror to about 90

degrees in a water bath. Do it in a clean container, not in a

dirty sink.

Use a thermometer or you can easily overheat the water. If

you're using plate glass for the mirror or tool, raise the temperature

of the water gradually or you may fracture the glass - you have now

been warned twice! From

here on,

I'm assuming everything is Pyrex. Once both pieces

are

heated,

remove

them from the water and apply polishing compound liberally to the

pitch.

Don't be afraid to wet the pitch and then sprinkle on a little

Cerium. Be wary that a little goes a long way, and don't waste

it.

Spread it out with your finger.

You want to get some Cerium

pressed into

the pitch right now. Put the lap on top of the mirror, which has

also

been wetted with some polishing solution. For an 8" lap, apply

about

15 - 20 lbs. to the back of the tool. After about 10 minutes, I

usually

remove the weight and separate the lap and mirror. Then I set the

lap back on and add the weight again. This presses even more

cerium

into the pitch. Press for a total of an hour and the lap should

be

in good contact. Have a tasty beverage and relax while the weight

does

the work. If the pitch is really soft and the channels close up a

lot, you are probably done with pressing. It should appear that

some of the polishing compound has imbedded itself in the surface of

the pitch over all of the lap. For Gugolz pitch, which is black

in color, this pitch will take on a grey, matte finish, rather than

black and shiny.

I use warm pressing when I need to "move" the pitch around a lot.

This

technique is dependable, controllable, and quite useful. Once

contact

is estabished at the beginning, you shouldn't need to warm press unless

you

don't use the lap for a while (a week or more). A lap that

requires

warm pressing every time you use it is probably TOO HARD. (Again,

that's

my opinion, and this is my web page.)

A cold press is NOT an option before ANY polishing or figuring session

-

you MUST do it. Raise your right hand and swear an oath that you

will

not start polishing without a proper cold press. Skipping the

press

is just asking for unpredictable figuring and worse.

Generally, I press with the mirror on the bottom, because the mirror

acts

like a bowl that retains liquid/moisture better. Spread some

polishing

mixture on the mirror surface. Spritz on some extra water with a

spray

bottle. Set on the lap, and add weight. You will have to

learn

to judge when the lap is in contact - for a medium softness lap 8" in

diameter,

intimate contact is obtained at the earliest after 1/2 hour. Want

a full hour if you have any question.

After time has passed, remove the weight and flip the mirror/lap over

if you are going to polish mirror-on-top (MOT). Do NOT separate

the lap and mirror. If the mirror/lap have dried out, decenter

the lap

or mirror slightly and spritz on the water or polishing mixture.

Gently rotate

the mirror or lap to distribute it, and start polishing.

Important - you should feel even, significant drag when polishing.

It should be the same in all directions and parts of the stroke.

You

should also feel drag if you spin the lap/mirror - it shoudn't spin

like

a top! If it spins easily, that's a sign that the center of the

lap

is in contact, but not the edge, or that the polishing mixture is too

thick.

If you have doubts on lap contact, stop and press, dammit!! This

is less critical during initial polishing when you're just removing

pits,

but SUPREMELY critical when your are spherizing or figuring.

NOTE:

For strongly aspheric surfaces (F/4 parabolas and faster), the

lap

drag will decrease as you decenter the lap during figuring. For

the

mirrors I'm discussing here, the drag may vary a little during

figuring,

but not too much. At any point, slipping/grabbing is a sign of

problems,

and pressing should be done immediately. Stopping to press is

encouraged

- it gives you a break from the labor of polishing, and encourages the

formation

of spherical surfaces. Press every 1/2 hour if you like,

esepecially

later in polishing. Pressing is often overlooked by those seeking

a

spherical surface. Without pressing, the lap shape can get out of

control

(especially with hard pitch) and the figure will follow!

0.4 - Polishing

For 4"-12" mirrors, I like to stick my palm to the back of the mirror,

and push the mirror forward while applying lots of downward pressure

through

the center of the lap/mirror. For larger mirrors, you can apply

both

palms. A 4" is challenging for anyone with large hands.

Just

a little moisture will allow your hands to adhere to the fine-ground

back

of the mirror (you did fine grind the back, right?). Another

option

is to use some of the rubber material that you put in the bottom of

drawers

that is intended to keep things from sliding. Try not to apply

pressure

with your finger tips or the back of the heels of your hands - make the

pressure

go through the center of the work through your palms.

I will note here that, especially later in polishing, you can often

feel when

the mirror isn't spherical if the lap is in good contact - the friction

will change slightly during the polishing stroke, indicating that the

lap and mirror don't mate perfectly for some position. My most

frequently obtained defect is high outer zones (also referred to as

TUE, but more than

the edge is turned up), and I can feel the just-pressed lap digging

into

it as the lap moves away from a centered position. After

polishing

a bit, this sensation is gone. This is because the pitch has been

pushed

up at and inside the edge of the lap, and the edge is not being worked

as much.

This

is a good time to stop and press, and then work on the TU zones some

more.

(Texereau's method of TUE removal has been very effective for me

for

high outer zones.

Vary the length of your strokes, and the side swing. The normal

polishing stroke is a stroke with a slight W to it, averaging 1/3 the

diameter of

the mirror (1/3 D) in length total. Do some longer, some shorter.

For

some reason, I get my best spheres with softer pitch, polishing MOT.

If

the edge is turned up at the end of polishing, I widen the W a bit to

make

the center deeper and head towards a sphere.

Trim the lap channels when they get narrower than 1/8" or so.

Keep the edge of the lap beveled. Try to be neat with

trimming.

After about 5-6 hours of polishing an 8" mirror, most of the pits

should be gone. Check the figure with a Foucault tester.

You should

begin practicing your testing skills now, and take enough time to learn

to take accurate readings. Others have covered Foucault testing

in

excellent articles - I assume the reader has attained a reasonable

degree

of testing ability, and can repeat readings to within a few thousandths

of

an inch for a moving source tester.

If the edge is turned down (TDE), I encourage some tool-on-top (TOT)

work. Volumes have been written on TDE, and I will let you read

them. In my experience, TDE is from imperfect contact, which is

often caused by the lap "riding" on top of a raised defect in the

mirror, such as a turned up outer zone (see my oblate sphere page), or

a layer of water and cerium oxide that is too thick. The layer of

polishing compound might be floating the mirror, causing the mirror to

tip slightly, and planing off the edge. If the polishing is done

without enough water, the lap and mirror can dry at the edge and more

wear then occurs there, causing a TDE. If you press down on the

edge of the lap without knowing it, or apply pressures that "tip" the

lap or mirror slightly as you polish, this can cause TDE. So,

keep good contact, spray on water when needed, and press down in the

center of the mirror.

TDE is different than a longer focus outer zone. Technically, the

edge of the mirror is the outer 1/8" or 1/16". That does

NOT include the outer zone!!!!! The outer zones

are the outer 1-2" of the mirror, and represent a large percentage of

the surface area of the mirror. Starting figuring with outer

zones that have a longer ROC than the central zones can actually be

beneficial, since some of the edge correction is already done. If

you don't see a diffraction ring all the way around the mirror, chances

are you have a TDE. It should be fixed before figuring. If

the outer zones have a longer ROC than the center, do a zonal Foucault

test and evaluate the figure of the mirror. You might be farther

along than you think. I have started figuring a few times with an

outer zone that's on the order 20% corrected, while the edge of the

mirror was good.

0.5 - Avoiding scratches

I have never strained pitch. I reuse it many times until it

becomes too hard and then it gets tossed. Getting pitch hot

enough to strain releases much of the volatile compounds that make it

soft and useful.

Scratches are caused by:

1) Incomplete polish - particles catch

in pits and cause scratches. The solution is to polish longer and

see further causes below.

2) Cleanliness issues - keep laps covered when not in use, and simply

wipe the mirror with the edge of your hand before polishing.

3) Poor quality cerium - decant bad cerium or buy better quality cerium. (I think this is the most common cause.)

4) Hard pitch or poor lap contact - use softer pitch and make sure laps are in full contact.

5) High polishing pressure - reduce polishing pressure. Often hard pitch and heavy pressure make for lots of sleeks.

Dust falls constantly, but I have never, ever seen a scratch from

it. Laps just absorb it, or it gets carried away by the cerium

slurry. Most sleeks during polish are from poor cerium, I believe.

This assumes a reasonably clean environment. What is clean to some

is not clean to others. If it doubt, just vacuum a lot and try to avoid

having strong breezes blowing through kicking up dust. Reasonable care must be used here.

You should worry more about the bigger particles that doesn't get

airborne. They have to get on the lap or mirror somehow.

So, just keep whatever is over the mirror clean. For me that's

the machine arm and tool, for polishing by hand that is the hands and

arms and sleeves.

1.0 - Figuring a mirror with a full-size lap

In order to start figuring, the following conditions should be met:

1) The mirror is polished out - no pits can be

detected.

2) You are comfortable with Foucault testing and can get

reasonably accurate, repeatable readings.

3) You know how to analyze data, or are comfortable using the

excellent free software available. (I use FigureXP.)

4) The lap is in good condition, of acceptable hardness, and in

good

contact. This is NOT the time to make a new lap.

5) The edge of the mirror is not turned down, and the surface of

the mirror appears smooth (not rough) under the Foucault test.

6) There are no major raised areas or depressed areas on the

mirror (zones). A TUE or raised center are okay, in moderation.

Every figuring step starts with a cold press long enough to obtain full

contact. This is not negotiable. Remember, contact is

everything.

Figuring is the process of making a fairly spherical mirror into one

that isn't a sphere. The parabolic shape that we desire is either

"deeper" than a sphere in the center, and matching at the outer edge,

or "flatter" than a sphere at the edge, and matching at the center.

A non-spherical shape in the mirror implies that the pitch must flow in

order to conform to the shape of the mirror once the mirror is

decentered

from the lap. While centered, the lap and mirror mate.

As

soon as a stroke starts, the pitch must flow to maintain contact, and

the action of the lap is

not

nearly as predictable. This is why figuring is so mysterious -

it's

tough to predict just where the contact between the pitch and mirror is

the

most intimate, and this is where the most action, or wear, is

occurring. Therein lies the art of making optics.

1.1 - Basic strokes - the normal

stroke

Let's start with the basic strokes - 1/3 D, COC. That's a stroke

that's a total of 1/3 the diameter of the mirror long, and the centers

of the mirror and lap coincide at some point during the stroke - COC =

center-over-center. Some side-to-side motion is fine, the stroke

doesn't have to go exactly

COC. There are two varieties of this stroke - MOT (mirror on top)

and

TOT (tool on top). Either stroke can be used to obtain a

reasonably

spherical mirror.

Figuring strokes are SLOW and deliberate, and gentle. Start and

stop

the strokes smoothly. Going too fast will cause the mirror/tool

to

slip and grab, indicating that you have lost contact. Slow and

smooth

strokes are a necessity, and allow the lap to stay in contact and

encourage

smooth optical surfaces to form. Smooth is important,

particularly

if you want to do demanding planetary observing.

When the pitch is reasonably soft and in good contact, and the two

surfaces are fairly close to a sphere, the area worked by the lap can

be assumed to

be most of the mirror, with more wear occurring near the edge of the

mirror

when the lap is on top, and more wear occurring near the center when

the

mirror is on top. Thus, a mirror with high outer zones (often

called

TUE) may be remedied by doing some MOT polishing to deepen the center,

thus

shortening its radius of curvature (ROC) to that of the outer zones.

This

may be quicker than wearing down the outer zones, and less likely to

turn

the edge.

However, when used on a non-spherical mirror, the results are not

as predictable. In general, the overall effect is similar,

though.

After a good cold press, MOT normal strokes (not parabolizing

strokes)

will generally help remove defects near the center of the mirror.

High

spots or low spots, such as a raised ring outside the center or even a

central

hole, can be "smoothed" using MOT normal strokes. The overall

correction

of the mirror will DECREASE, though, but this is remedied by switching

back

to the parabolizing stroke. Using the TOT normal stroke, defects

in

the outer zones can often be smoothed. In general, MOT normal

strokes

will reduce correction near the center earlier (as the central area is

more

likely to spherize) than the edge, and TOT normal strokes will reduce

correction

in the outer zones more quickly than the inner zones. This is not

a

hard and fast rule, but I have found it to be reasonably dependable.

So,

overcorrecting the outer zones can be remedied by TOT normal strokes.

A

hole in the center can be helped by MOT normal strokes.

With the purpose of normal strokes now understood a bit better, it's

time

to start figuring. If have started figuring from spheres, from a

shape

with a raised center and partially corrected outer zone, and from

variations

of these. So long as the deviations from a sphere are fairly

smooth

(no deep troughs) and are only 20% or 30% of those of the ideal

parabola,

figuring can generally begin, as long as the edge is good.

1.2 - Alternative parabolizing

strokes

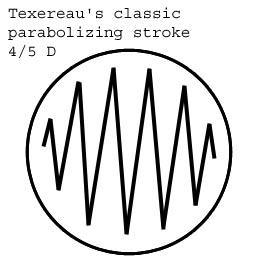

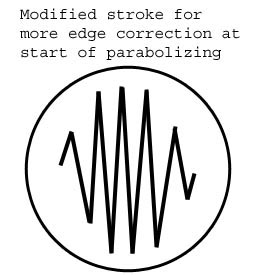

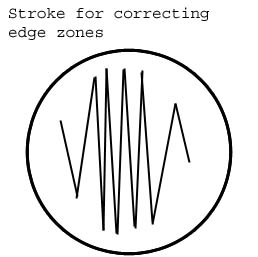

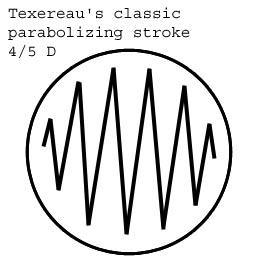

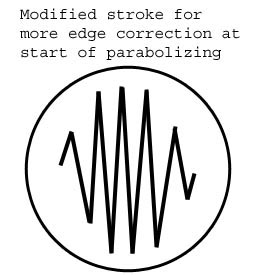

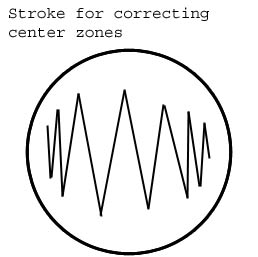

Below on the left is a picture of Texereau's recommended parabolizing

stroke.

On the right is my recommend parabolizing stroke to start

with.

Both are done MOT, with slow, smooth strokes. The line

depicts

the travel of the center of the mirror over the lap.

The most common error I see with parabolizing with a full-size tool is

polishing

a deep central hole into the mirror with little edge correction added.

So,

until the worker knows how the lap is going to act, start with the

stroke

on the right. This will add more correction in the outer zones of

the

mirror. Hopefully, smooth correction will be added from the edge

to

center. Center correction is EASY to add by decentering the

mirror,

and we can do that later, after the edge is in good shape. I

recommend

working with the stroke to the right for about 10 minutes. Keep

the

mirror/lap wet to slow down the polishing action, and keep the strokes

slow

and smooth. The weight of the mirror is all the pressure that is

used.

Towards the end of the 10-minute session, you may feel differring

amounts

of friction when the mirror is centered and when the mirror is offset.

This

means the lap/mirror have changed shape, and a cold press will be

useful

soon.

So what is correction? Correction is departure from a sphere.

In

our case, while all of the mirror surface is being polished, the most

glass

is being removed near the center. This means that the central

zones

will have shorter ROCs than the outer zones. Starting with the

central

zone and moving out, each zone has a longer ROC than the one before.

I

define the difference in ROC between two zones as the "difference" or

"delta".

Example 1.1:

We are figuring an 8" mirror with a full-size lap. It's of

moderate

focal ratio.

We are using a 4-zone Couder mask for the Foucault test. The

ideal readings

for the Foucault test are: 0.000", 0.020", 0.040", 0.060".

We note that the total correction is 0.060" - that is, the difference

in

ROC between the outermost and innermost zones is 0.060". The

difference

between any two adjacent zones is 0.020". (Getting the same

"correction",

"difference", or "delta" between each adjacent zone is possible by

designing

the mask openings such that each annulus (ring) has the same surface

area.

The mask opening shows a part of this annulus.)

Let's say the stroke I described above works well. We might see

the

following readings after doing the Foucault test: 0.000", 0.005",

0.015",

0.030"

Now we compare the differences between the zones (deltas) to the ideal

deltas.

The measured deltas are: 0.005", 0.010", 0.015".

Divide each measured delta by the ideal delta (0.020") and multiply by

100

to get the percentage correction. We get: 25%, 50%, 75%.

If the mirror tested perfect, we'd see 100% for all three. These

percentages

represent how much the slopes of the two adjacent zones differ.

The Foucault test measures slope, and in figuring we make the

zones have different

slopes. The slopes get shallower of "flatter" as we move out from

the

center. As it is, the corrections we measured are higher as we

move

out That means the slope differences are greater as we move out

on

the mirror, and closer to the ideal relationship. We would say

this

mirror has more "outer (edge) correction" than "inner correction".

This

would be the ideal outcome of using the stroke I described above.

The

next step in figuring this particular mirror would be to adopt as

stroke

that introduced more center correction and less edge correction, and to

sneak

up on approximately 100% correction in each zone.

Example 1.2:

For the same 8" mirror mentioned above, we take the following

measurements:

0.000", 0.015", 0.025" 0.030"

Calculating the corrections (find deltas, divide by ideal delta,

multiply

by 100), we get: 75%, 50%, 25%

We have a corollary to the case above (Example 1.1). Now, the

central

zones have more correction in relation to each other than the outer

zones.

(This is a similar to a central hole, but a central hole often

occurs

when the outer zone correction is near %0.) In this case, we need

to

adopt a figuring stroke that corrects the edge more than the center,

which

has already been described. Hopefully this can be done without

overcorrecting

the central zones. If this occurred, some MOT normal stroke work

might

reduce it. Okay, I'm getting ahead of myself.....

Okay, let's discuss the examples. In Example 1.1, the mirror

needs more

correction in the center than in the outer zones. In Example 1.2,

the

mirror needs more correction in the outer zones than the central zones.

These

are two typical results after a couple figuring sessions.

The goal of figuring is to bring the correction (differences in ROCs

between

the zones) to the ideal values at the same time. This is a bit

like

herding cats, but it can be done, I assure. The key is to SLOWLY

add

correction and CONTINUOUSLY adapt our technique. We'll sneak up

on

a nice smooth parabola and surprise it by aluminizing it before it can

get

away!

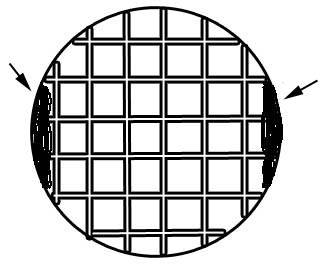

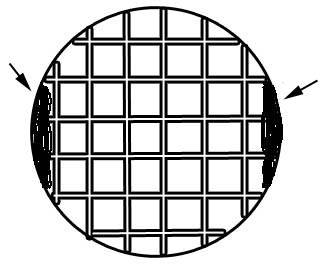

So why do we use the strokes described above? Here's the

principle

involved in parabolizing, and in lots of figuring: The

pitch

lap can be visualized as doing most of its work at the edge.

For simplicity,

I'll

refer to the figure below. So, when figuring, imagine the

indicated

parts of the lap working the most on the mirror. When the

mirror

is offset to the side, the center of the mirror is nearly over the edge

of

the lap, where the action is. Thus, the center is being worn down

more

than the rest of the mirror. If the mirror is slightly

decentered,

the area worked most on the mirror is the area just inside the edge,

like

the outer zone or two. So, if we modify the parabolizing stroke to have

more

forward and back strokes when a certain part of the mirror is over the

edge

of the lap, then that part of the mirror will generally get more

correction

added than the other areas. That's it in a nutshell - that is the

one

guideline that will let you figure a mirror!

Now this part of the lap is not the only part that is active and

polishing,

but it can be a very powerful visualization tool. If you mark the

zones

on the back of the mirror with marker, you can easily see when they are

passing

over the these areas of the lap and adjust your strokes. This

will

take practice and adjustment depending on your lap and polishing style,

and

you will have to observe where the correction happens - it may

happen

just inside or just outside where you are visualizing it, and

this

is why figuring is an art, not a science.

Remember that to add correction, you must change the slope relationship

between

two zones - if you want to increase the correction between zones 1 and

2,

then you can "wear away" zone 1. Then zone 1 has a steeper slope

than

zone 2, and the correction increases. If you wear away both

zones a much smaller change or no change in correction may occur.

With this "active" lap area in mind, we now understand why the

following strokes

work

to do what they do:

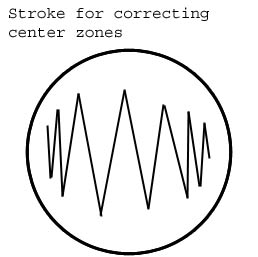

The stroke shown in the first figure may be effective in bringing the

mirror

in Example 1.1 closer to the ideal parabola. With this technique,

the

center of the mirror is over the edge of the lap. Most correction

is

added to the center.

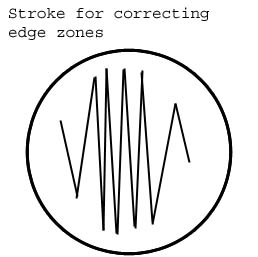

The stroke shown in the second figure may be useful for Example 1.2.

Here,

the edge of the mirror passes most often over the edge of the lap.

Correction

is added in the outer zones, mainly. Care should be used with

this

stroke, and a careful watch should be kept for signs of a turning edge.

Well, this may seem like a very short, fairly simple explanation of

figuring,

but the techniques described above are just about it. Together

with

a good computer program to reduce the date, you can make an excellent

mirror

by following these guidelines:

1) Try to add correction in the outer zones first. Test

often.

2) Modify the polishing technique to add center correction once

the

outer zones are 50% corrected or so.

3) Try to bring all zones to correction at the same point.

It

is much easier to correct the center when the edge is done than to

correct

the edge when the center is done. Try to get the edge right

first, if possible.

4) Use a computer program to find the "high spot" on the mirror,

and

(gently and slowly) wear it away using the "active lap area"

visualization mentioned above.

1.3 - Computer analysis programs

- A very good thing

Use software that you are comfortable with to produce an error profile

of

the mirror. Try to make the outer zone flat - that is, adjust the

ROC

in the program until the outer zone has zero error. For an

undercorrected

mirror, the central area of the mirror will appear high (possibly VERY

high),

indicating that more parabolization is needed overall to reduce the

central

error. Once the corrections are within 30% or so of 100%, take a

closer

look at the error plot. It may indicate the high areas are fairly

specific

- say a high center or a raised 80% zone. If so, work these areas

over

the edge of the lap with some side-to-side blending motion to keep the

surface

smooth.

I have used FigureXP quite a bit and I like it. The latest

version

lists % correction between adjacent zones, the same number I used in

the

examples.

1.4 - Some Final Tips

Don't forget the normal MOT and TOT strokes. If you get in a

situation

where the correction is high, then low, then high as you go from the

center

of the mirror to the edge, you have a "kink", as Zambuto has called it.

A

kink can also have low, then high, then low correction. The first

type

(high-low-high) indicates a raised area. The second

(low-high-low)

indicates a depressed zone. These should show up on the error

profile.

These kinks can be reduced by applying one of the normal strokes.

If

the kink is near the outer edge, do TOT. If it's near the inner

edge,

do MOT. Overall correction will decrease, but you will have a

smoother

mirror, and you can just start back in with parabolizing. The

normal

strokes are a "soft reset" or "undo" button.

Don't be afraid to go back towards a sphere - it will help you out.

Usually

the tough problem that you're avoid will be replaced by a simpler

problem,

like a high center. Also, you don't have to go all the way back

to

a sphere - you can just back off the correction (anywhere from 20% to

80%)

until the problem is gone, and then start parabolizing with a MODIFIED

technique,

based on your figuring experience and how you think the lap and surface

will

react. Continuous adjustment is the key. Take it slow, back

up

if necessary, press often, and you will eventually progress to a good

figure.

1.5 - Example mirror, 6" F/6

mirror figuring log

After this mirror was polished, high outer zones remained. A good

amount of TOT work was done to remove it. When I started

figuring,

the outer zone had about 0.010" of correction in it already, and the

edge

was good.

For figuring, I use a slow-acting refined Cerium oxide. Decanted

Cerium or Rouge would work fine too. Also, only very light

pressure was applied to the lap.

The pitch lap was fairly soft - 0.086" of fall were measured for a 1 kg

mass in 5 minutes. Temperature was 68 degrees. Pitch was

Gugolz

55 and some harder pitch mixed in.

Step 1: 15

minutes of my

standard parabolizing stroke (not Texereau's), with less center

emphasis.

Also, shorter strokes when going COC to avoid further correcting

edge

at this point, since it already has some correction. For the

following

Foucault readings, R = reading of KE position, R-R1 = reading minus

first

reading, and ideal is the ideal KE reading for a perfect parabola, all

in

thousandths of an inch.

Foucault readings: Zone # R

R-R1 Ideal Correction

-----------------------------------------

1 88

0 0

2 92 4

17 Z1-Z2: 24%

3 99 11

32

Z2-Z3: 47%

4 109 21

46

Z3-Z4: 71%

So, we observe that the outer zones are more corrected than the inner

zones. This is fine, since the center is easier to correct.

Step 2: 10 minutes parabolizing

stroke, with a bit of extra action for center of the mirror, that is,

when

the mirror overhangs most.

Foucault readings: Zone # R

R-R1 Ideal Correction

-----------------------------------------

1 65

0 0

2 81 16

17

Z1-Z2: 94%

3 90 25

32

Z2-Z3: 60%

4 104 39

46

Z3-Z4:100%

This step produced full or nearly full currection between zones 1 and 2

and between zones 3 and 4. The correction between zones 2 and 3

is

lagging.

Step 3: Go to short normal strokes to widen

central

hole and generally reduce correction, and even it out. Do 1/6 D

strokes

with a little side swing for 6 minutes. Do 5 minutes of

parabolizing

strokes afterward to add a little correction back..

Foucault readings: Zone # R

R-R1 Ideal Correction

-----------------------------------------

1 50

0 0

2 63 13

17

Z1-Z2: 76%

3 72 22

32

Z2-Z3: 60%

4 85 35

46

Z3-Z4: 93%

All zones reduced, but this effect was the most pronounced in the

center

zones, since we did MOT. Need to add correction outside of zone

1,

in zones 2 and 3.

Step 4: 8 minutes of normal parabolizing

strokes,

with some emphasis on zones 2 and 3. That is, when zones 2 and 3

are

over the edge of the lap, more forward-and-back strokes were performed.

Foucault readings: Zone # R

R-R1 Ideal Error Correction

-------------------------------------------------

1 65

0 0 0

2 81 16

17

-1 Z1-Z2: 94%

3 90 30

32

-2 Z2-Z3: 93%

4 104 45

46

-1 Z3-Z4: 107%

FigureXP shows ~1/30th wave P-V on the wavefront.

Surface is smooth,

and edge is good. Slight work on the transition between zones 3

and

4 could improve the figure, but at some risk. Alternatively, the

normal

parabolizing stroke, avoiding working the center, could improve the

numbers

slightly. Working time would be a minute or two. This

mirror is done.

Well, there's the process of figuring a moderate F-ratio mirror in 4

steps.

This mirror lives in my travel scope. It is a good

planetary

performer. F/6 is a good compromise for this size mirror if you

want

to observe planets and deep sky.

Hope this example was helpful. Here's a link to the FigureXP file for this mirror. Right click

to download the file ("save link as").

Clear skies

and

happy figuring,

Michael

Lockwood