Large Grinding Machine

The 32" F/4 mirror requires a large machine to grind and polish.

John

Pratte wanted a machine for himself, so we decided to scale it up just

enough

to handle the 32". The machine was built by John in his shop with

help

from Bob, and the turntable was used to dewedge the blank. After

this,

the machine was disassembled, painted, and brought to my house, where

it

was reassembled in my basment where the work will be done. Here

is

a photo of the parts in the van parked in my driveway (with Bob Holmes

and

John looking on), and a photo of all the bolts that had to be installed

to

put the machine back together.

The frame was assembled without too many incidents in the basement.

It

is shown below at the left. Bob Holmes is standing on the left,

John Pratte is on the right. The rest of the assembly of the

shafts,

bearings, pulleys, gearboxes and other parts went mostly without

incident,

but a little "under the chassis" debugging was required to quiet a

noisy

coupling, and this work is shown in the next photo.

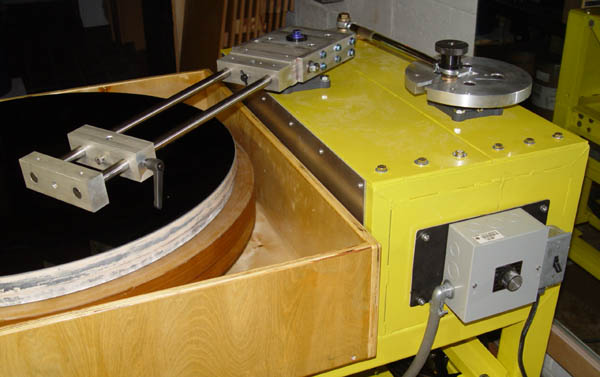

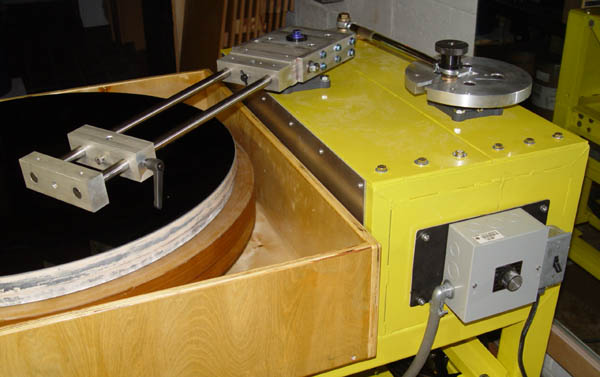

Finally, below is a photo of the completed machine, complete with

turntable,

wooden drip pan, and the 32" mirror sitting on the turntable for

completeness.

Lastly, here are some photos of the drive shafts, belts, and gearboxes,

and

the drive arm and eccentric.

Bob also built a nice tilting test stand out of steel tubing so that

the mirror can simply be slid off the turntable onto the stand and

tilted nearly vertical for testing.

Now it is up to me to finish the mirror so Bob can finally get his

scope

operational and doing research. It is long overdue (due to no

fault of ours), and I can't wait to see it producing

images. It will be fun to work on a big mirror again!