Tests of a 6.0" x 0.8" quartz disk

by Michael E. Lockwood

Earlier this summer a seller of quartz disks offered to give a 6"

diameter disk to anyone who would test it and post results. I

thought this would be an interesting piece to test by various methods.

I sent the seller

a note and offered to perform some tests. The seller agreed, and

the

disk arrived less than a week later. No other payment was

received

in exchange for this work.

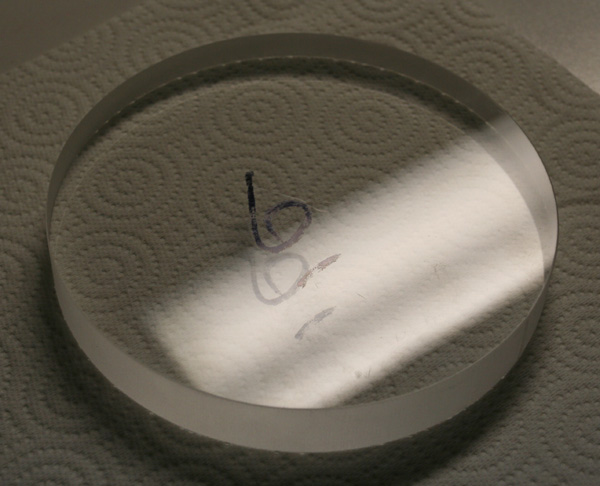

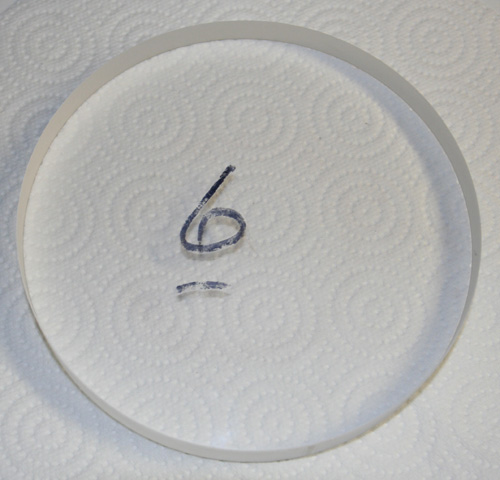

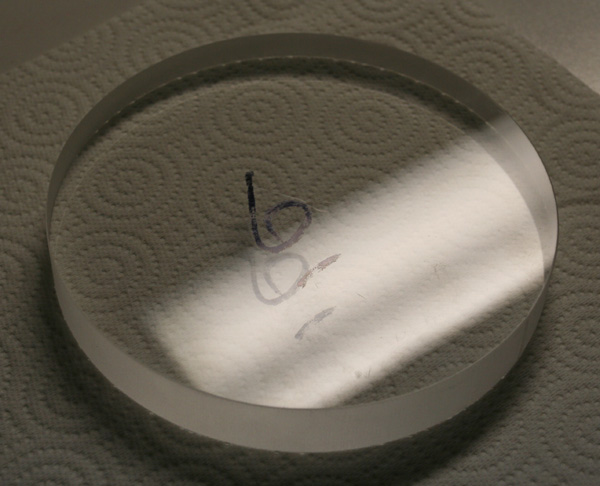

Packing, phsical description

The disk was received, packed very nicely in foam in a box. A

couple

of photos of the disk are shown below, along with an image of the

package

and packing that it arrived in in excellent condition.

The disk was polished on both sides. Both sides had light

scratches and pits on the surface, but overall the disk was in very

good condition.

The edge was fairly smooth and the disk had a slight bevel to

prevent

chipping, but some texture from cutting the disk remained on the edge

in

the form of smoothed bumps.

The physical dimensions of the disk were measured with calipers and a

micrometer, and are summarized below:

Diameter - between

5.990" to 5.998"

Thickness -

between 0.8001" to 0.8018", wedge of

0.0017"

The wedge is enough that the quartz could not be used for an optical

window

without reduction of the wedge through grinding.

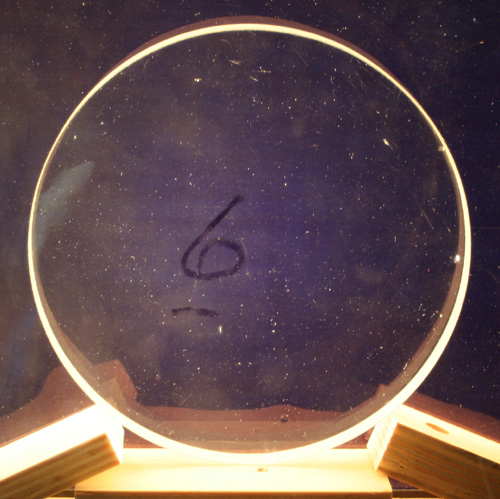

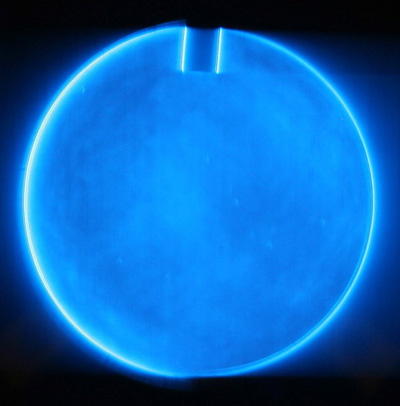

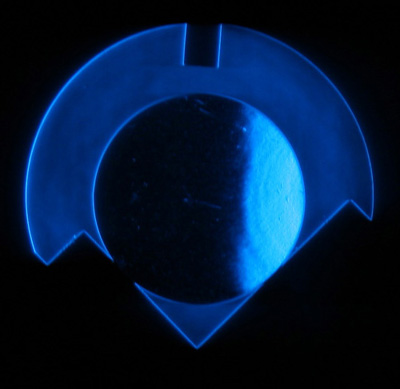

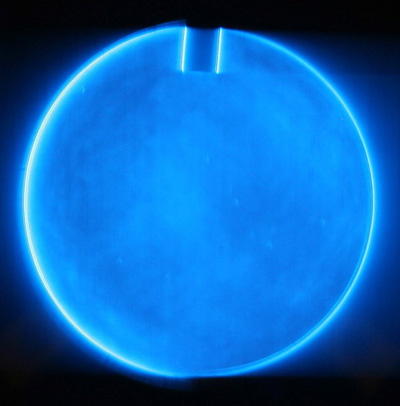

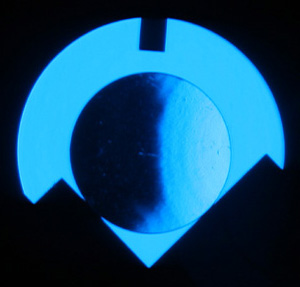

Strain Testing

The disk was tested for strain and no

strain was detected. A

photo

of the test is shown below. Uniform darkening indicates an excellent

anneal.

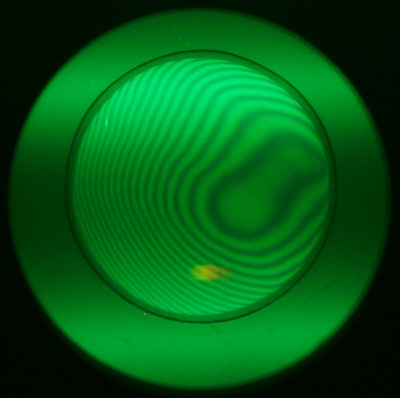

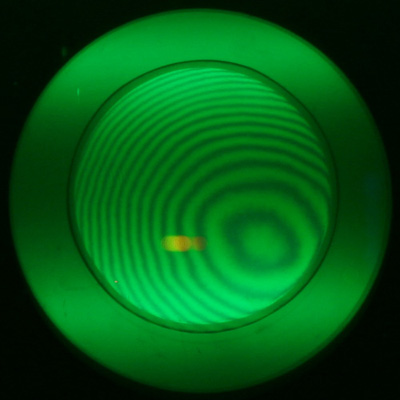

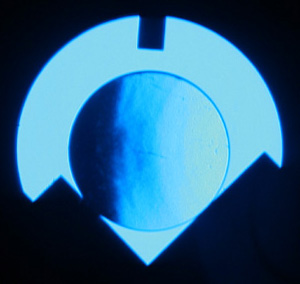

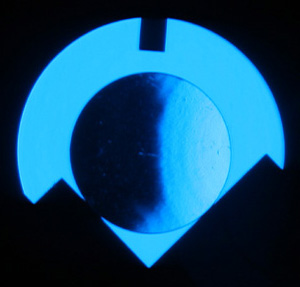

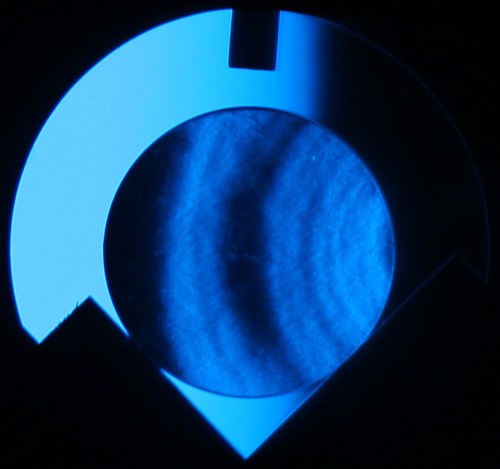

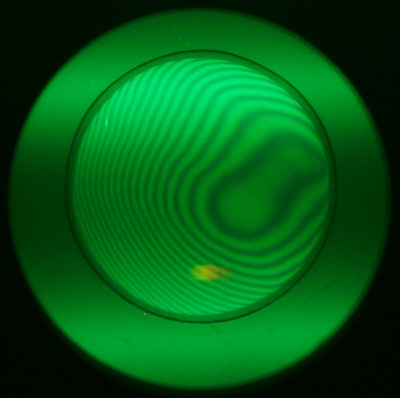

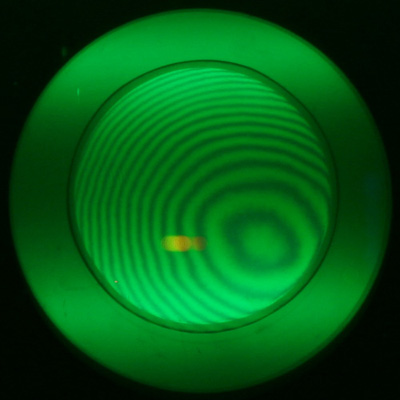

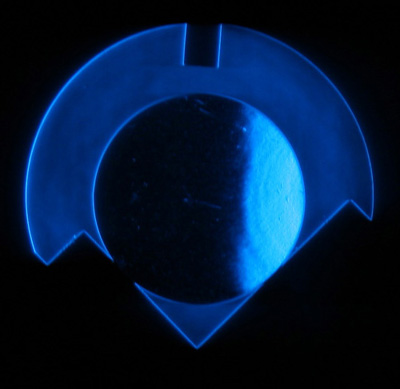

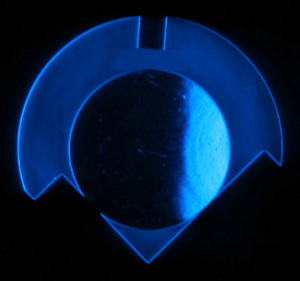

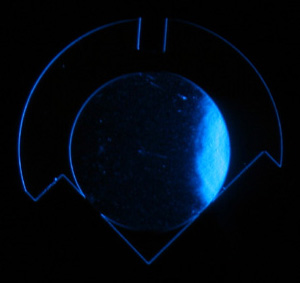

Surface Flatness

Next, the flatness of each surface was measured by placing an optical

flat

in contact with it. Both sides

were found to be significantly

convex,

on the order of about 7-8 fringes, or approximately 3.5 to 4 waves.

The

figure was also a bit irregular. These are more reasons that this

quartz

could not be used for a window in the condition it was received.

Images

of the contact interference testing using monochromatic light are shown

below

for both sides of the disk.

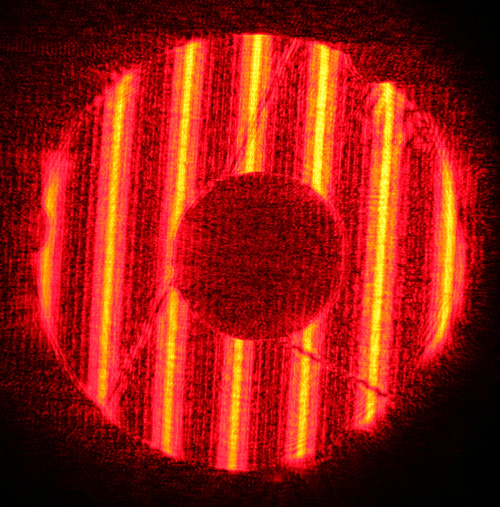

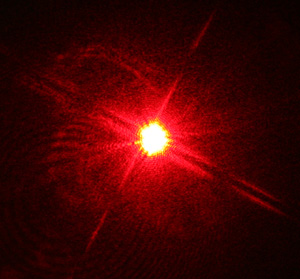

Transmission - collimated laser light

The first test of the quartz in transmission

was done by placing it

between

a 4.25" F/4.5 Newtonian telescope (see my telescopes page) of known

good

quality and a source of collimated (parallel) laser light. Below

is an image

of

the 4.25" system (only) under test showing its good correction with a

ronchi grating near the focus.

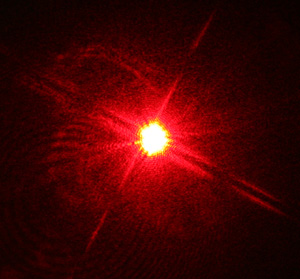

This laser light is just like light coming from a star - it is

parallel,

and is focused by the telescope into a star image. The image

formed

by the telescope was photographed as best I could through an eyepiece,

and then the

quartz

was introduced between the telescope and collimated light and

the star

image

photographed again. The introduction of the quartz caused a

noticeable

defocus of the image (due the convexity of the faces) and some

asymmetry

in the image (due to wedge and irregularity of the convex sides).

As this 4.25" F/4.5 is a very low-power telescope, it is not a very

tough

test for a window. Therefore, failure in this test indicates that

the quartz

was

not suitable for use in transmission without further work to flatten

and

parallelize the two faces. The focused image is shown on the left

below

without the quartz, and on the right with the quartz between the

telescope

and collimated light.

Transmission - using reference sphere

Finally, the disk was tested in transmission using a very accurate

spherical

mirror with a radius of curvature of 246.5". The quartz was

positioned

in front of the sphere approximately 1" away from it. A photo of

the test setup, the

(coated) spherical mirror with the quartz sitting in front of it, is

shown

below. Thus, this constitutes a double-pass test in transmission

for

the quartz disk. The light from the test device passes through

the

quartz, bounces off the spherical mirror, and then passes through it

again

on the way back to the tester/analyzer.

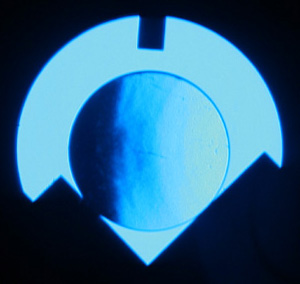

Below at left is an image of the sphere under test without the quartz

in

front of it. It shows a fairly good null. Thus, any

deviations

caused by the quartz will appear as dark or light spots when it is

placed

in front of the sphere. At right is an image of the quartz in

front

of the sphere, with the tester still positioned at the radius of

curvature

of the sphere. It is noted that one side of the quartz darkens

before

the other, indicating that the quartz has refracted the light and light

passing

through it comes to focus at a different location than the sphere.

In

this case, the radius of curvature

was shortened by approximately 2" by

the

convex faces of the quartz forming a weak lens.

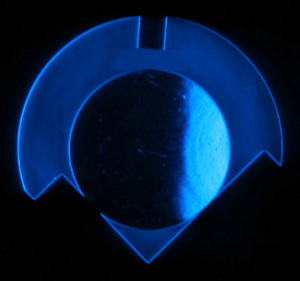

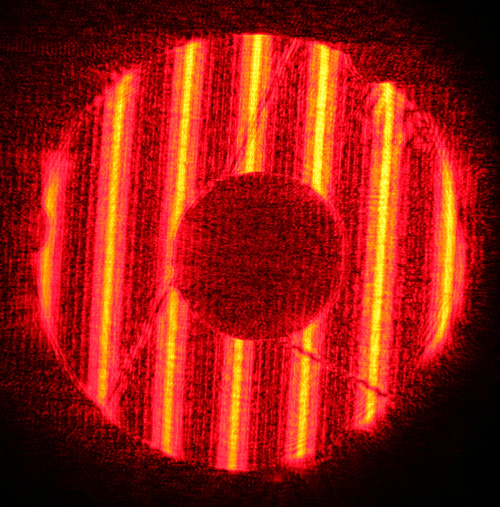

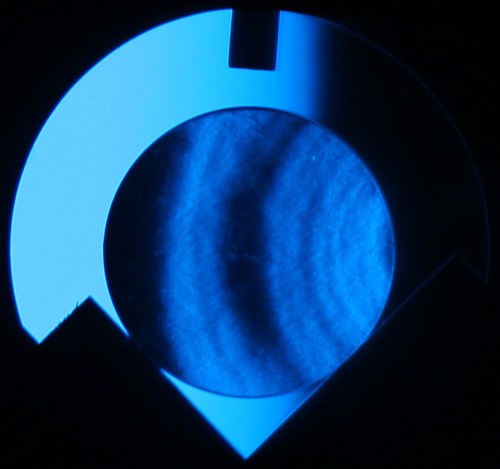

Below is a series of images taken as the knife edge is brought into the

beam,

showing some of the irregularities in the surface of the quartz disk.

By moving the knife edge toward the

spherical mirror approximately 2",

the

knife edge is close to the radius of curvature of the quartz/sphere

system,

and the surface irregularities of the quartz may be more readily seen.

The

image below shows this quite clearly. Note the semicircular

features that are

either

on the surface of the quartz or due to subtle variations in the

properties

of the glass throughout the disk. Without first de-wedging the

blank

and then figuring both sides to at minimum a figure of revolution (flat

is

best, but a figure of revolution will do), I cannot say more about the

source

of these features. I think they're on the surface, though.

I plan to de-wedge the blank and figure one side to an accurate flat in

the

future, and then figure the second side to fairly close to flat.

No idea when this will be done.

Conclusions

1) This blank would make an excellent substrate for a

flat mirror, an uncoated

optical flat (with one or two figured faces), a Newtonian primary

mirror,

or a convex Cassegrain secondary mirror.

2) While it is possible that it may work well as an optical window

after further grinding, polishing and figuring to get both sides flat

and parallel, I

could not

say for sure unless I did that work and tested it again in

transmission. I am not likely to do that - most likely I will

flatten one side or use the quartz for a Cassegrain secondary mirror.