Fixing the Cassegrain Mount

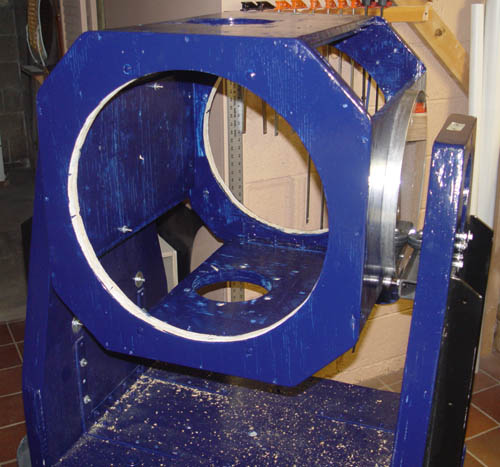

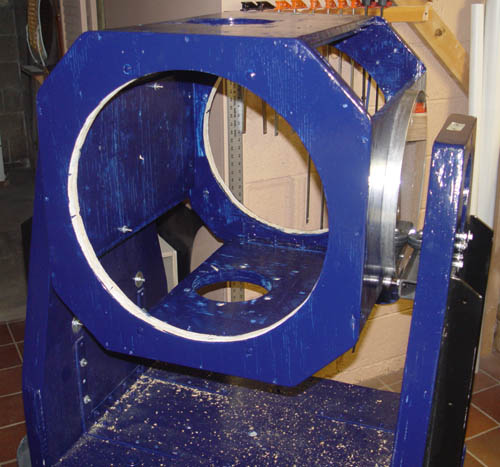

Well, after much work on the optics, it's time to fix the mount for the

Cassegrain.

The old declination bearings were just plain worn out.

Here's

a picture of the tube cradle, tube, and the old declination bearings

after

disassembly. A picture of the massive right ascention shaft is

shown

next.

Mike Conron took the tube cradle and the fork to his garage for

cleaning,

sanding, and a new navy blue paint job. The cleanliness of his

hands

was sacrificed so that the wooden scope parts would be protected from

the

elements, as shown in the next photo. Then the "movers" pictured

brought

the fork into my basement for further work.

I obtained two 14 3/4" diameter by 1" thick aluminum disks from S&S Machine

in California for a very reasonable price. They are machined

round,

and the faces are polished, as shown in the next picture. (No,

the

reflection did not break the disks.) These were then bolted to

the

newly-painted tube cradle, which sits on rollers in the fork mount

(next

photo). Great care was taken to make sure the disks were

concentric

and as parallel as I could get them.

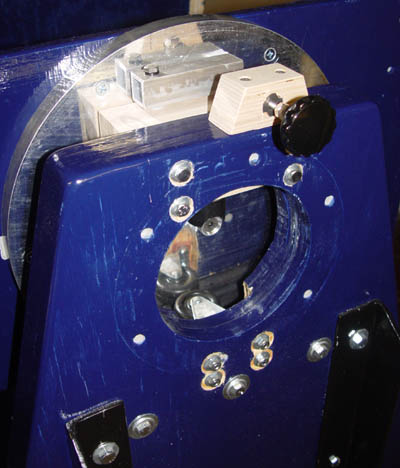

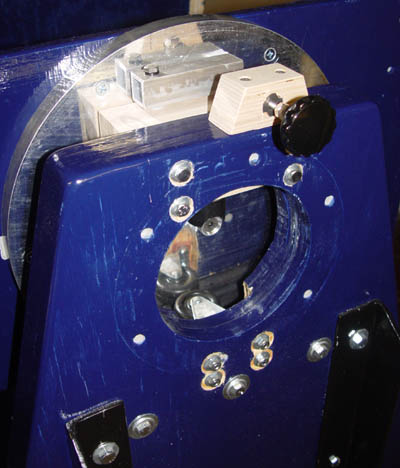

The next two pictures show the rollers and caster which constrain the

movement

of the aluminum disks. The rollers are mounted to 1.5" square

steel

tubing (3/16" thick wall) on the inside of each of the fork arms.

The

rollers bear the vertical load, and the casters support the lateral

load

which is at a maximum when the scope is pointed to the east or west.

The

second picture is a closeup of the disks and rollers together.

After this, I made the two "keeper" assemblies that make sure the disks

stay

seated on the two lower rollers. These were simply two bearing

assemblies

that attached to the center of each disk. One utilized a 5/8"

bearing

with a 5/8" aluminum cylinder inside the bearing that was bolted to one

of

the disks. The other bearing was a 1" diameter aluminum cylinder,

bolted

to the other disk, with a piece of nylon, cut out to match the 1"

cylinder,

which constrains movement. Both bearings were attached to the

fork

using pieces of plywood (Baltic Birch). This permits a slight

amount

of "give" if the center holes in the disks are off slightly. I

also

added a device to vary the friction of the declination motion.

Here's a closeup of one of the bearings and the friction adjustment.

The result is that the declination axis motion is very smooth, and most

of

the physical construction on the telescope is done. Now we need

to

drill the new mounting holes in the tube for the mirror cell and one

fan,

paint the new parts and touch up the fork and cradle, install fans, and

reassemble.