Mirror Removal and Initial

Inspection

Here are some pictures from our

"mirror removal party", on the evening

of September 23, 2004.

A nice sunset, as we get ready to disassemble the scope. Those

present were Guy Hampel (who brought lights and extension cords), Phil

Wall, and myself.

We fired up

the generator for lighting and took quite a few measurements of the

scope and the mirror positions. Next, I did a quick star test of

the optics, and Guy tried to snap some photos of the patterns through

the eyepiece with his digital cameral. With the documentation

finished, we proceeded to remove the primary

mirror and cell.

A view down the tube, looking at the primary mirror and baffle.

The secondary mirror is above, a bit out of focus. The secondary

mirror was not centered in the tube and could rattle around in its

holder, and neither mirror appeared to be

in proper collimation based on a visual inspection of the secondary

tilt and the star test. The second picture is the mirror and

cell, after removal from the tube assembly. Phil Wall is standing

behind it. The mirror is 3.5" thick, about 16 3/8" in

diameter, and weighs about 50 lbs. It's one beast of a mirror.

I took the mirror and cell home, and washed off as much of the dirt as

I could. I placed the mirror on my large test stand to take a

look at the figure, but the shadows weren't right - there was a huge

amount of scatterred light. Immediately I knew the coating, 6

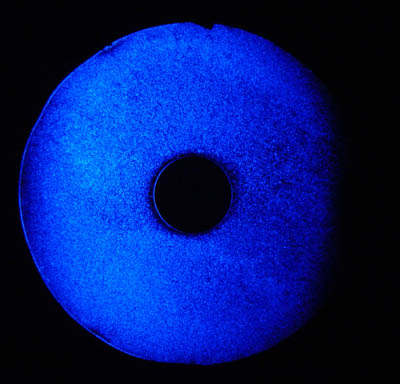

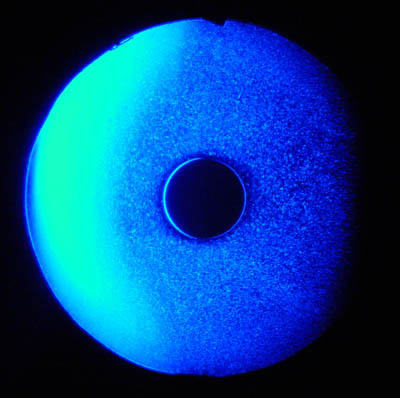

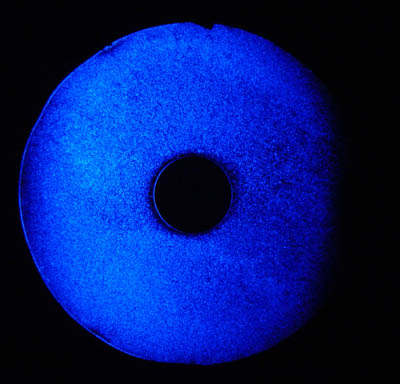

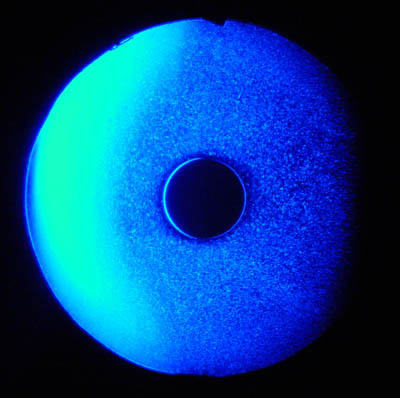

years after Clausing did it, was finished. Above are two views of

the mirror under the focault test.

Illumination

source is a blue LED. For the image at left, the light spots are

reflective portions of the coating that are scattering light out past

the knife edge. Dark portions are either failed coating areas or

areas that are not scattering light. The image at right has the

knife edge removed from the beam more, so that the left edge of the

mirror is more intensely illuminated. This mirror has obviously

experienced

a severe coating failure.

In the interest of documentation, I wanted to illustrate just how bad

it was. So, I came up with a quick way to illustrate the

failure. Here are some pictures of the coating inspection, using

a lamp to

illuminate the mirror from behind The whole-mirror view shows my

reflection. The closeup shows the true extent of the coating

loss.

Some have told me that Clausing coatings (at least the Beral variety)

fail when exposed to salt air, and when exposed to temperatures above

100 degrees F. Moisture could also be a culprit. In any

event, I am quite sure the coating has been in bad shape for some time

now, likely at least a year or longer. So, I'll rate the 5-year

lifespan of this coating as poor, and the coating itself as

unacceptable. I will recomment overcoated aluminum for the next

coating, from L&L Optical Services in CA, Spectrum Coatings in FL,

etc.