Secondary Mirror Fabrication

The secondary mirror for the 16.25" F/12.5 classical cassegrain will be

5" in diameter, with a radius of curvature of 50.21". Its conic

constant is -3.44, and its amplifying power in the Cassegrain system is

3.32 X. The mirror and test plate (tool) will be ground and

polished at the same time. Then the test plate will be figured,

and the mirror will be matched to the test plate using interference

testing.

Oct. 21, 2004:

The glass for the secondary mirrors arrived today. I will be

doing the club 5" secondary in parallel with my own 4" secondary, for

my future 12.5" F/12.5 classical Cassegrain. The F/4.2 primary is

currently being refigured. My secondary has an ideal ROC of

47.33".

Nov. 7, 2004:

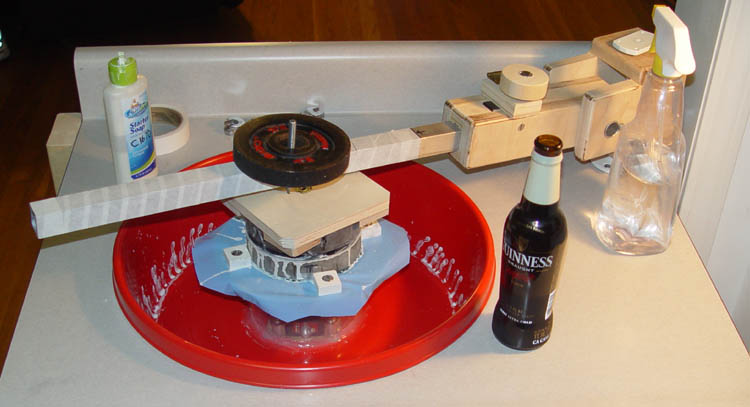

My grinding spindle is now complete and operational. Today I

started grinding the secondary mirror and test plate with 80 grit

carborundum. I hogged out the F/5ish curve in about 1.5 hours,

while learning how to use the spindle best. The spindle speed was

between 60 and 90 RPM.

The mirror still has an unground spot in the center

that's about 1" in diameter and shrinking. When it is gone, I

will grind the backs flat and hog out the curve of my 4"

secondary. I finished refiguring my primary on Nov. 3rd, (mirror

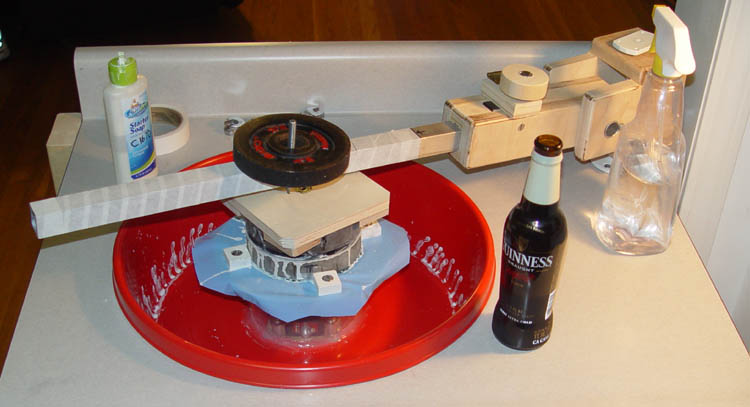

#14 for me!). Here are some small pictures of the

turntable. The first picture shows the view - I can sit

comfortably and grind mirrors while watching TV (Yes, that's Red Green

on the screen). The second picture shows a larger view of the table top

and speed control (grey box at lower right). The two larger

blanks are the 5" secondary and test plate, the smaller ones are the

4". I can sit with my legs under the machine, so there's no

strain on my back. Three hours of work causes very little

fatigue, which is quite different from three hours of "walking around

the barrel".

As of 11:30pm, the mirror has a low spot in the

center about 1" in diameter that hasn't been ground yet.

Hopefully another hour of grinding will eliminate it. The test

plate has been ground over the whole surface. The sagitta is

still very close to the desired value of 0.0622".

Nov. 9, 2004:

As of this evening, I'm done with 80 grit on both secondaries and test

plates. The backs have been ground flat, and the curves are close

to their ideal values. Time to move to 120 grit. I also put

together a first working version of a spherometer tonight, and it's a

very convenient way to check the curves. I'll post a picture of

it soon, and I already know I need a more accurate dial indicator for

it.

Nov. 11, 2004:

After the CUAS meeting I finished 220 grit on both mirrors. Time

to move on to 25 micron aluminum oxide. My spherometer (pictured

below) indicates that the sagittas of both mirrors are near their ideal

values. After some fine grinding, I'll verify this with the

flashlight test.

Here's the spherometer, sitting on a cheap

optical window that I use to zero it. The spherometer uses a 4"

diameter pulley as a base, with a 3/8" bushing pressed into the 1/2"

bore of the pulley. The dial indicator fits in the bushing.

On the underside of the pulley are three 0.375" diameter bearings,

epoxied into three holes that are as close to the same distance apart

as I could get them. The bearings are approximately 1/4" in from

the edge of the pulley. They are also as equidistant from the

center hole as I could get them.

The dial indicator is new

and dependable and reads to 0.001", but I am shopping for one with a

resolution of 0.0001". The blanks next to it are the 5" secondary

and test plate and my 4" secondary and test plate.

Nov. 14, 2004:

I have finished 25 micron on both mirrors. Initial tests with

light indicate that the ROCs of both mirrors are fairly close to their

ideal values, in agreement with the spherometer measurements.

(The spherometer was calibrated by measuring mirrors of known

ROC.) I

will get more accurate tests after grinding with 12 micron.

Nov. 16, 2004:

I have FINISHED FINE GRINDING both mirrors/test plates. The

sequence was 25, 12, and 5 micron (MicroGrit, which is great stuff, by

the way) aluminum oxide. The

ROCs are within approximately 0.125" of their ideal values, on the

shorter side. This was the desired result. The quality of

the finished grind is quite good, with no noticeable defects. The

last two abrasives only required 20 - 30 minutes of work, not including

slight ROC adjustments accomplished with 5 - 10 minute MOT or TOT

grinding spells. At 12 micron, it appeared that 10 minutes of TOT

shortened the ROC by about 0.25". Lengthening the ROC takes

longer since more glass must be removed.

Polishing will be done MOT until an accurate ROC can

be determined with the Focault test. Time to make some pitch

laps! Also, I need to polish the backs of the blanks (using a

high speed method) so that interference testing is easier.

Nov. 19, 2004: Poured

and channelled the four pitch laps for the two mirrors and test

plates. I also drew plans for an adjustable manual overarm for

the machine, and started glueing together the wooden parts.

Nov. 21, 2004:

Finished the overarm and installed it. Polished the 5" test plate

for about 2.75 hrs with the machine. It is very nearly polished

out! Machines are great! ROC is just under 50 inches, a

little low. Some more TOT (test plate on the bottom) polishing

should correct this and result in a complete polish. Here's a

picture of the overarm during polishing. All the items in the

picture are critical for the successful completion of the project.

Nov 28, 2004:

The secondary and test plate are polished out. The test plate has

been partially corrected (about 40%), and I'm bringing the radius of

the mirror closer to that of the test plate. The test plate is

essentially a 5" F/5

mirror with 3.45 times the normal correction (with respect to a

parabola). The ROC has held at 49.9", about 0.3" short of the

ideal value. This error is within tolerance, and will make the

focal ratio of the instrument F/12.55. This effectively

adds a small amount of back focus, which is fine.

Dec 2, 2004:

The 5" test plate now has a wavefront error of around 1/3 wave P-V

(peak to valley). The goal is 1/10 wave P-V wavefront error or

better. Not far to go now.

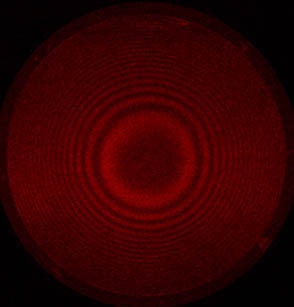

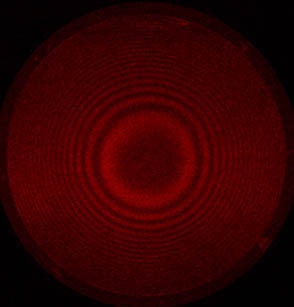

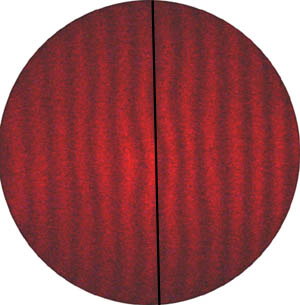

Dec 6, 2004:

The 5" test plate is DONE. Two focault test masks, one with 5

zones and one with 4 zones (centered on the borders of the 5-zone mask)

were used independently to check the figure. Both indicate a

wavefront accuracy of 1/18 wave or better, P-V. This is quite

good. What remains now is to match the secondary mirror to the

test plate using interference testing. Currently there are about

17 fringes of difference between the two, as shown in the image to the

right. The test plate is concave relative to the mirror, so I

will be working the outer part of the mirror to make it more convex.

Dec 6, 2004:

The 5" test plate is DONE. Two focault test masks, one with 5

zones and one with 4 zones (centered on the borders of the 5-zone mask)

were used independently to check the figure. Both indicate a

wavefront accuracy of 1/18 wave or better, P-V. This is quite

good. What remains now is to match the secondary mirror to the

test plate using interference testing. Currently there are about

17 fringes of difference between the two, as shown in the image to the

right. The test plate is concave relative to the mirror, so I

will be working the outer part of the mirror to make it more convex.

Figuring the test plate was not easy, but I managed

it with only the full-size lap. About 7 waves of glass were

removed at the center of the test plate to add the correction.

The knife edge (KE) movement (for a moving-source tester) was about

0.170". For comparison, with the same tester my 16" F/4 had

~0.240" of KE movement, and the 30" F/3.8 had a bit over 0.500".

So, for a small mirror, it's quite corrected. The key is that it

is of good figure, and after matching the mirror to it we will have an

excellent secondary.

Convexing the mirror will start in earnest tomorrow

night.

Dec 8, 2004:

I made a harder lap and carved out the center, and made tapered facets

that got wider toward the edge. After 1 hr. of using this on the

turntable, (mirror on the turntable, rotating about 60 RPM, lap held in

my hands and not turning), I am down to 12 fringes of relative

concavity around the outer 1" or so, and a 4-fringe bump in the middle.

Dec 10, 2004:

Now it's 8 fringes around the edge, and a small bump in the

center. Thanks to Bob R. for the "polishing fuel", in the form of

a Guinness 6-pack. I enjoyed talking with everyone at the CUAS

holiday party.

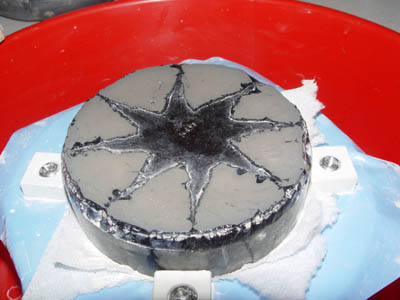

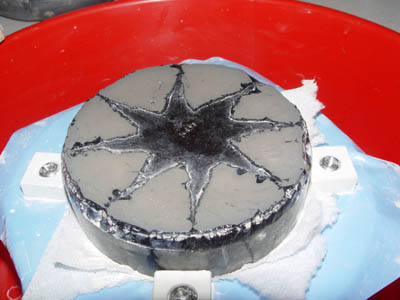

Here's a picture of convexing lap versions 1 and

2. These were used to wear down the edge and make the secondary

more convex to match the test plate. With these I went from the

previous fringe picture to about 2 fringes of error fairly quickly and

painlessly. Some polishing with the full lap was intermingled to

keep things resonably smooth. The turntable was indispensible in

this process, in my opinion. (Hold lap in hands, move about 1/4"

stroke, watch mirror spin underneath at 45 RPM, watch TV, let spindle

do the work!)

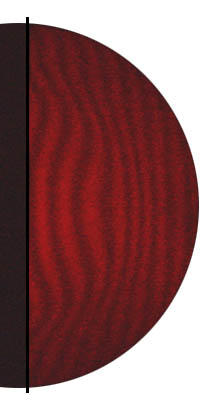

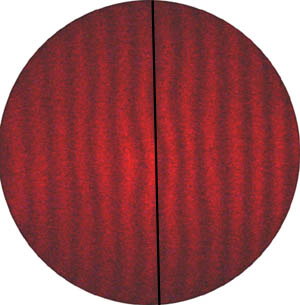

Dec. 13, 2004:

Well, it is a good day. I think I can now say that the new optics

are now at the same level of accuracy as the old optics were, that is,

about 2/3 wave of error on the wavefront. The secondary now has

about 2/3 fringe of error (and fringes ARE the wavefront).

I have been using the second convexing lap to

carefully work down the edge, and smoothing from time to time with the

full lap, 1/3 of 1/4D stroke with heavy pressure and slow

strokes. Pressing is done every 5-10 minutes. There were

also some figuring strokes done to reduce the raised zone at the 50%

zone.

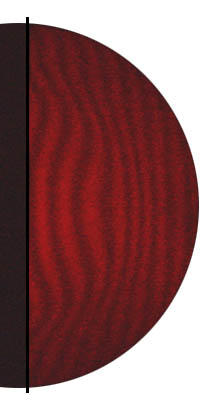

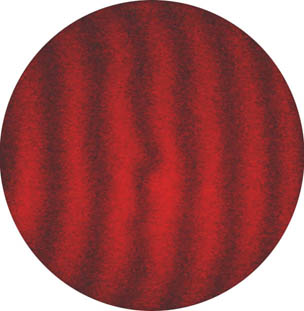

Here's a picture of the fringes, taken right after

my last work session (last night). Curvature to the right

indicates a high zone in the mirror. As of today, the error

has decreased about 1/3 fringe from the picture. The right half

of the mirror is shown, and the black line is my digital attempt to

provide a straight reference line. A bump is visible at the 50%

zone, and there is a slight turned edge. The edge is coming back

with continued work.

Matching a convex surface to a concave reference is

an excellent way to observe the effects of different figuring strokes

and techniques. This is lots of fun. Right now the entire mirror

is convex with respect to the edge, so I just have to wear away the

"high spots" as they appear.

Dec 14, 2004:

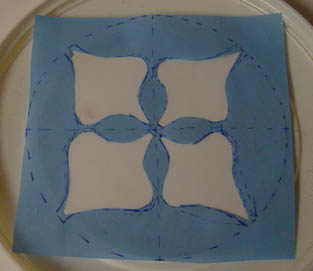

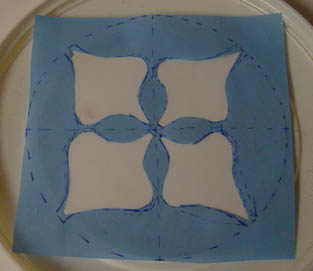

I made a petal lap to work down

the high 50% zone. It worked quite well, and the outer edge

continues to come up. Two 8-minute sessions were done, as well as

a few sessions of slow MOT polishing to remove some slight

convexity. Here's a picture of the petal lap pattern, cut out of

a piece of blue plastic, that was used to press in the pattern.

The pattern was freehanded, just using my judgement, no fancy computer

design. After the work the picture to the right below was taken

of the fringes. The straight black line was added digitally for a

straight reference line. (The goal of the figuring is to finish

with straight fringes.)

The center of the mirror is about 1/3 fringe

high, and the 60% zone is about 1/4 fringe high. Another petal

lap will be made to work these areas down a bit. Working time

will be on the order of minutes. Now the figure is at the point

where the atmosphere and thermal effects will be the limiting factors

in performance on most nights. Stay tuned.....

Dec 15, 2004:

The figure has improved farther, but the temperature in the house

hasn't been stable enough to get the mirror and test plate equalized to

take a picture. I used a couple more petal laps to bring down the

high zones seen above. This morning I did a quick figuring

session to work on the last remaining "up" zone near the edge, and I

will see the results when I get home.

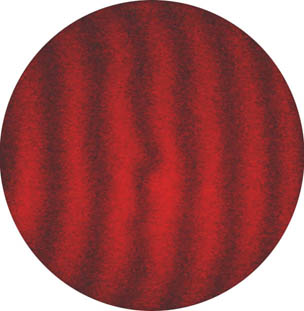

Dec 16, 2004:

Well, this should be the final fringe photo. Ignore the small

bump in the center, it's hidden by the secondary's shadow. The

fringes are slightly curved, but this curve is smooth. This

indicates that the mirror is slightly convex with respect to the test

plate, but this small difference in ROC only changes the correction

insignificantly. Thus, the mirror is a nice hyperbola, but a

slightly more convex one than the test plate. Additionally, the

fringes indicate that the surface of the mirror is smooth. What

does this mean? The mirror is accurate, smooth, and

DONE!!!!! Now we just need an improved declination axis, and some

cooling fans......

That's all

folks. Time to pack up these optics and get them off the coater,

and start polishing my own Cassegrain secondary. I'll have to

start a page for that scope, which will start construction as soon as

the secondary is done.

That's all

folks. Time to pack up these optics and get them off the coater,

and start polishing my own Cassegrain secondary. I'll have to

start a page for that scope, which will start construction as soon as

the secondary is done.

THE

END

Dec 6, 2004:

The 5" test plate is DONE. Two focault test masks, one with 5

zones and one with 4 zones (centered on the borders of the 5-zone mask)

were used independently to check the figure. Both indicate a

wavefront accuracy of 1/18 wave or better, P-V. This is quite

good. What remains now is to match the secondary mirror to the

test plate using interference testing. Currently there are about

17 fringes of difference between the two, as shown in the image to the

right. The test plate is concave relative to the mirror, so I

will be working the outer part of the mirror to make it more convex.

Dec 6, 2004:

The 5" test plate is DONE. Two focault test masks, one with 5

zones and one with 4 zones (centered on the borders of the 5-zone mask)

were used independently to check the figure. Both indicate a

wavefront accuracy of 1/18 wave or better, P-V. This is quite

good. What remains now is to match the secondary mirror to the

test plate using interference testing. Currently there are about

17 fringes of difference between the two, as shown in the image to the

right. The test plate is concave relative to the mirror, so I

will be working the outer part of the mirror to make it more convex.

That's all

folks. Time to pack up these optics and get them off the coater,

and start polishing my own Cassegrain secondary. I'll have to

start a page for that scope, which will start construction as soon as

the secondary is done.

That's all

folks. Time to pack up these optics and get them off the coater,

and start polishing my own Cassegrain secondary. I'll have to

start a page for that scope, which will start construction as soon as

the secondary is done.