32" F/4 Dewedging

Well, sometimes things just don't work out.

The photos of the 32" F/4 BVC mirror on my "Foucault Testing Hall of

Shame"

page are of a friend's mirror. Bob Holmes hunts supernovas and

minor

planets - he does real research - and his newly built 32" scope waited

for

its mirror for nearly a year and a half before we got the blank back,

wedged,

unfinished, scratched, and complete with tens of waves of astigmasitm.

The

blank had lots of wedge - 3/16"-1/4" or so. Therefore, the first

step

to finishing it was to dewedge it.

For this task, the large machine that John Pratte and Bob built was to

be

used to provide the turntable, with a borrowed diamond tool and a DC

motor

providing the grinding power to true up the blank. The motor and

tool

ride on a wooden beam that can move across the blank manually, and is

simply

clamped in place while the mirror rotates underneath. Here is a

photo

of Bob (left) and John (right) with the machine and the dewedging

apparatus.

(They

smiled when the work was done!) Also, below is a photo of the

motor

that turns the tool, hooked up to the speed control from my small

grinding

machine.

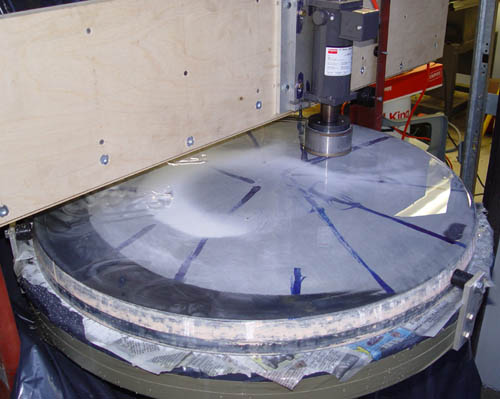

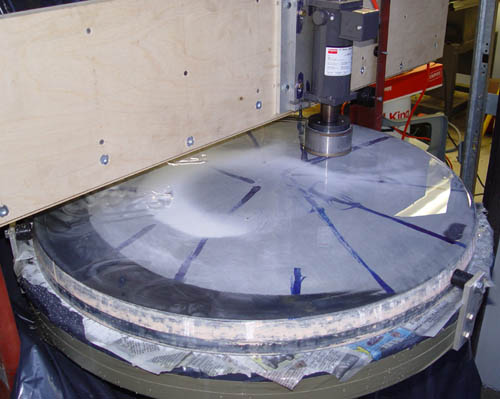

Below is a photo of the machine, covered in plastic, ready for the

dewedging

operation. On the right is a photo of the dewedging operation

after

a few passes. The left side of the mirror shows a darker area

where

the blank has been ground. The blue lines are ink that help show

where

the blank had been ground.

After quite a few hours of work, the back of the blank is now quite

flat,

and ready for regrinding and refiguring, which is my next task.

The

grinding was done slowly and with constant water lubrication to avoid

generating

dust or vapor containing glass particles. It was nice to see

ourselves producing the same sort of "generating marks" that we have

only seen on commercial blanks!