November 19,

2011: How

to pack a mirror properly (my way)

This

is how I usually pack mirrors up to and including 24" in diameter.

A 26" would probably be OK, too. Larger mirrors use similar

methods, but are packed in wood crates and shipped via freight.

The keys are - use a strong box, tape it securely, and make sure there is at least 2" of foam on all sides of

the mirror. It's nice to have 3" on the sides if possible.

For small mirrors, 1.5" might be enough. Sometimes

other high-quality,

flexible foam is used (the white crumbly stuff is weak, annoying junk),

and occasionally cardboard is stacked on top to help fill

up a box if there is empty space at the top.

Some

shippers might promote the "squishy box" theory - that is, cushion the

blow. However, I'd say that I promote the "foam brick" theory.

The blow may not be cushioned, but a truck could run over the box

and the mirror would probably survive. The harder foam also

resists penetrations a bit better than softer stuff. Admit it -

you've received a package with a nasty-looking hole poked in it at some

point, so think of that when packing your mirror.

In this example, a 24" x 1.5" mirror is packed into a 30" x 30" x 6"

(inner dimension) heavy-duty Uline box. The box was cut down in

height from its original 30".

Uncoated mirrors are easier to clean and less delicate than

coated mirrors, because the coating is more easily scratched. In either case, the mirror should be cleaned before

shipping so that dust or dirt do not harm the surface during the

vibration and shocks/drops of shipping.

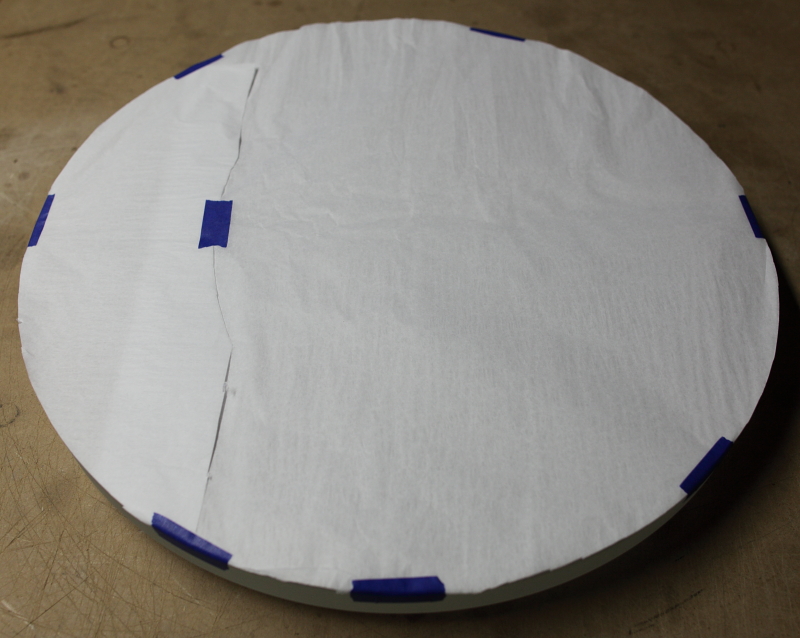

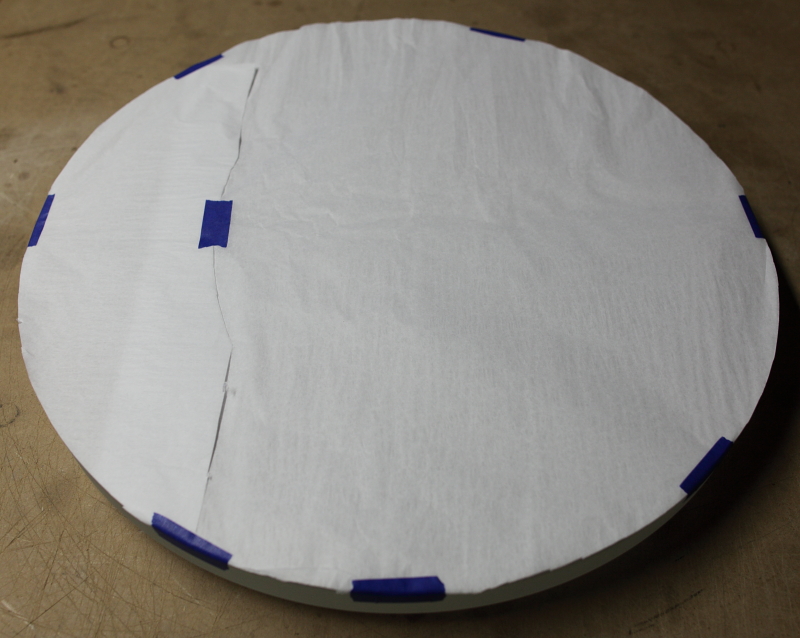

First,

the mirror is cleaned. Then a few layers of acid-free paper is

taped over the clean mirror's surface (below). The paper should

not be able to move around. Acid-free paper will not react with

the mirror's surface if the mirror is not unpacked or shipped promptly.

If you don't have it, try to find soft tissue paper free of dyes,

lotions, or other chemicals, and try to minimize the time that the

paper is agains the mirror's surface.

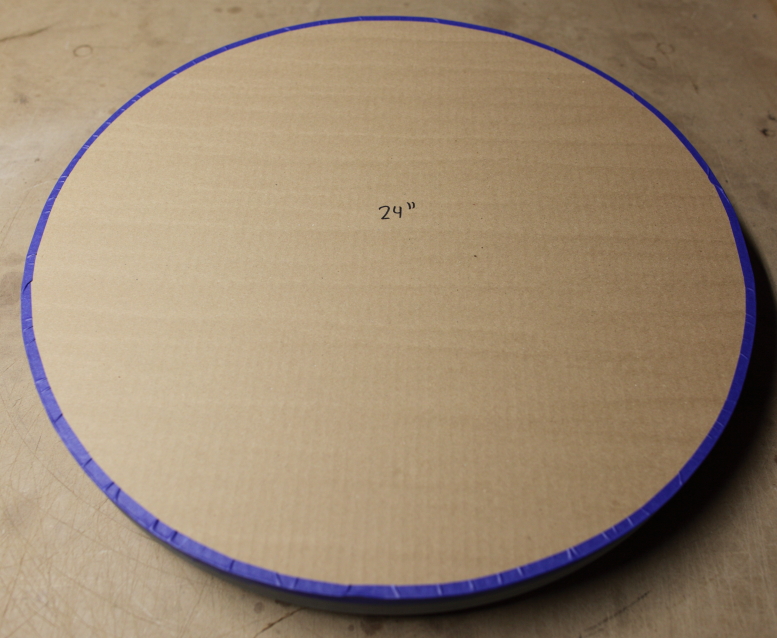

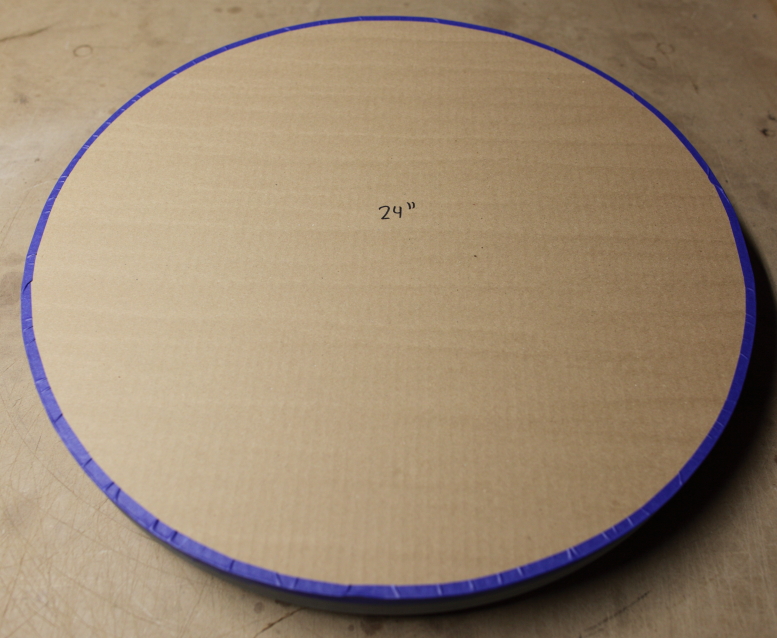

Next,

a cardboard disk is cut and taped securely over the paper, preventing

anything from getting in between, holding the paper stationary,

and protecting the surface. A coater once told me that regular

masking tape was leaving a residue and was making his job harder, so I

immediately switched to the blue painters-type tape.

The

mirror is placed in a box with foam cut to fit snugly around it

(below). I use a small, cheap bandsaw to cut out the circular

hole for the mirror. A knife will do a messier job, but will

work. A hot-wire cutter would be nice.

The mirror should

not be able to move around, and cardboard can be wedged in around the

edges of the mirror or box, or on top of the mirror to take up extra

wiggle-room. In this case, a few pieces of loose cardboard were

placed on top to keep the mirror from moving vertically.

Finally, the box is filled the rest of the way with foam.

The flaps are securely taped where they meet, the edges of the

box/flaps are taped, and I also run tape around the box to further

strengthen it. Any corners that appear weak are also taped.

Don't forget to check the bottom of the box, where flaps are

often not taped. Use wide, good quality packing tape. It's

worth it.

The goal is to make the box as rigid as possible - any

flexure of the box is bad, and will allow the contents to move or

shift. It will also stress the tape, corners, and other weak

points of box.

In short, it is my goal to ship a foam "brick" that can only be opened with a knife.

You

can also see why I charge for a new packing box. The foam and box

are not free, and it takes me some time to get everything to fit

properly. It is also incentive for the shipper to pack it

properly in the first place!

Shipping

insurance is an option,

but with this type of packing your mirror should withstand rough

handling and make it to its destination OK unless the truck goes up in

flames or the plane crashes. That is quite unlikely, and in terms

of statistics, the mirror is far more likely to be lost than damaged

like that.

To reduce the chance of loss, I print my shipping labels ahead of

time and drop the boxes off at a staffed location (usually

FedEx/Kinkos) when I am in town. They don't add additional

charges like the UPS Store. Having a label helps reduce address

errors and time spent waiting for a clerk to do it. I would use

UPS if there were a more convenient drop-off location near me that

didn't up-charge.

So far the only problem I have experienced was

with a small mirror shipped by the USPS, as I was instructed to do by

the client. The post office managed to get the box wet, damaging

the coating because it was not immediately dried out.

Here are some more thoughts on packing:

I have to buy 30"x30"x30" boxes in a quantity of 10 each, shipped

freight from Uline. I buy many sizes at a time, and they all show

up in flattened form on a pallet. I have forks for my tractor so

I can load and unload crates, pallets, etc. Most new boxes are

too large to ship UPS or FedEx. Then I have to custom-cut the 30"

boxes down to the right height, typically ending up about 7" tall

including the thickness of the top and bottom of the box.

I ship up through 24" and 25" mirrors in cardboard boxes. For

these large sizes, the boxes are triple wall and are taped with high

strength professional tape, such as 3" Kraft paper tape with strands of

reinforcing fibers imbedded in it, and 3" wide clear packing

tape. For lighter, smaller mirrors, double wall works fine.

I take great care in taping up the boxes inside and out to strengthen

them, and I tape the corner of the box where the seam is. Taping

properly is very important to the structural integrity of the box.

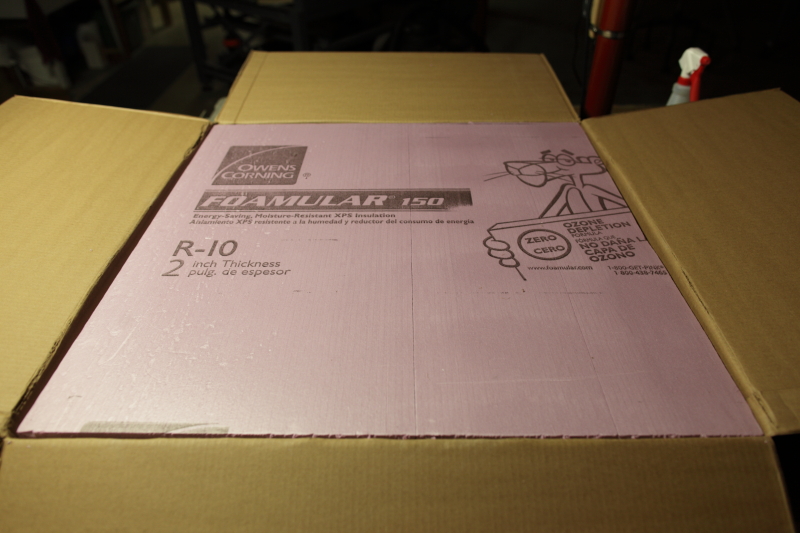

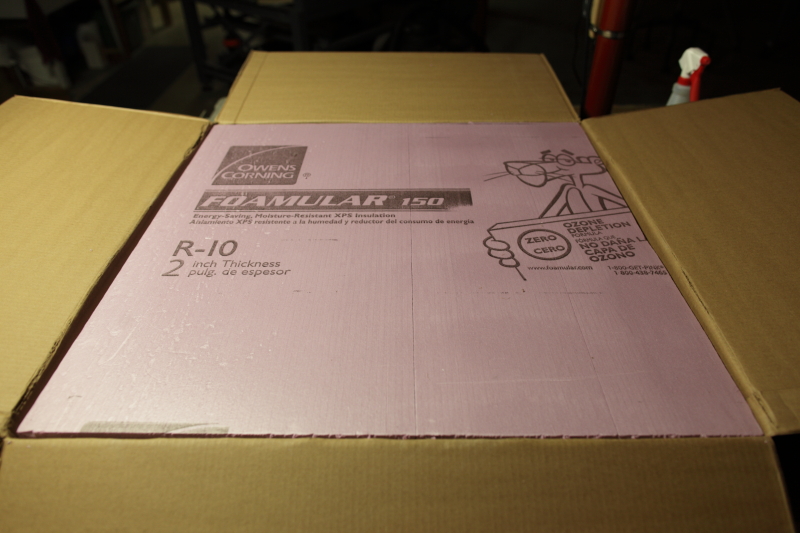

I like to have a minimum of 2" of foam on all sides of the mirror, and

3" if possible. For example, I ship a 22" mirror in a 28"x28"

box. I use 1.5" and 2" thick hard foam (typically blue or pink,

sold in 4'x8' sheets at home improvement stores) cut as accurately as

possible so that the mirror does not have room to bounce around in the

box. The less the mirror can move, the less it will beat up the

foam internally. I have also experimented with hot-gluing the

layers of foam together, and reinforcing the sides of the box with thin

plywood to help make the box more durable. Still, shipping large

mirrors in a box will lead to the box and packing eventually getting a

bit beat up.

When cutting the foam, cut a place where whomever is packing/unpacking

the mirror can get their hand under the mirror to lift it out of the

foam. I typically do this closest to the corner of the box,

cutting a ~4"x1" piece out of the layer that goes around the mirror,

and making a depression in the layer underneath so one can get their

fingers under it. This will encourage nicer handling of the

mirror and the box and foam, and this is good all around.

Shipping freight is a pain and can be expensive if you don't regularly

work with a freight company like I do, and don't have a machine capable

of picking things off trucks. Avoid it when you can.

It has been my experience that UPS and FedEx see wooden crates as a

CHALLENGE, not something that is protecting something inside!

It's like they try to find ways to break them. They also hate

handling them because they are hard to handle and because of splinters.

So, if sending a wooden box via these shippers, be nice wrap it in a

layer of cardboard or put the wooden box in a cardboard box. This

will help it to be treated more kindly by everyone, in my experience.

If you can find sheets of heavy cardboard (it is sold for packing

purposes), you can MAKE YOUR OWN BOX. Use a roller (dull pizza

cutter) to "score" a line along which the cardboard can be

folded. Buy a roll or two of high-quality, 3" wide tape and make

TWO boxes, one nested inside the other. Then put foam inside of

that. That should get your mirror there safely, and it will be

re-usable.

Lastly, insurance purchased through UPS and FedEx is expensive.

Also, you may have problems getting a claim simply because the item is

glass. So, you may be paying this money for nothing. I

typically don't insure mirrors of this size - I pack them

properly. (My business insurance covers some of this

now.) If packed properly, the primary risk of shipping is

LOSS or THEFT. So, sign up for a UPS or FedEx account and print

the label yourself. You can get better rates this way, too.

Put tape over it to protect the label. Also, put another copy of

the label inside the box, just in case. Make quite sure the

address you are shipping to is correct, and that someone will be there

to sign for it when it is received. Checking the "signature

required" option is a good idea. Likewise, ask that you be

informed when the mirror ships back to you, and get a tracking

number. If you sign up for a free service like "UPS My Choice",

you will get an email when something is shipped to you, and you have

options to have it held if you are not going to be home, etc. The

best way is simply to be there personally to receive the mirror when it

comes back. All of this greatly reduces the chance of loss.

After you ship or receive your well-packed mirror, please check back for future installements of "In

the Shop".

Mike

Lockwood

Lockwood Custom Optics