July 16, 2019: Testing Large Flats

All text and images copyright Michael E. Lockwood, all rights reserved, unless otherwise noted.

Testing large flats is not simple.

For modest-sized Newtonian flat secondary mirrors, shaped like an ellipse so that they look round when they are angled at 45 degrees, the simplest way is to use contact interference testing, or place them directly on a reference flat. Typically I use a quartz or Zerodur reference flat. To get an accurate test, one must wait for the mirror under test to equilibrate with the reference flat and air. See my older article here for some flats tested with this method, and also note the green interferogram in the heading of this article.

The contact interference testing method works well if one is patient and the temperature is steady. However, testing larger flats can become quite difficult and risky due to the mass of the test mirror and limited size of the reference flat. At some point, when flats become larger than 7" or 8" minor axis, the major axis (long axis) is then 10" or larger, and it can overhang the reference flat and be difficult to test. Also, the flats can start to flex significantly, and any dirt caught between the two mirrors can cause scratches or other damage.

I had originally planned to build a 12" Fizeau-type interferometer with a 12" quartz flat as a reference element. This would allow non-contact testing of up to 12" round flats. However, with my purchase of a 4D PhaseCam recently, that opened up the possiblity of a larger Ritchen-Common test arrangement. The 4D is a very powerful instrument, and it allowed me to to test and make a 24" f/2.4 quartz sphere that was approximately 1/20th wave, as measured over an average of over 600 measurements! The analysis software also has a built-in analysis algorithm for Ritchey-Common testing, making things even simpler.

In R-C testing, the diverging test beam from the interferometer, with its focus located at the radius of curvature of the sphere, first bounces off the (possibly uncoated) flat under test, which is positioned at an angle that sends the light toward the sphere. It then bounces off the (coated) sphere, off the uncoated mirror under test a second time, and then returns to the interferometer. This makes it a double-pass test, so errors on the flat are multiplied by two for extra sensitivity. With proper calibration of the interferometer, this means that large, very accurate flats can be made.

While

not much light returns to the interferometer due to two uncoated

bounces off the mirror under test, the typically 45-degree angle of the

mirror under test actually reflects more light than at normal

incidence due to polarization effects, so this makes testing somewhat

easier than other

arrangements with two bounces off an uncoated mirror (such as testing a

Cassegrain system with an uncoated secondary mirror).

While

not much light returns to the interferometer due to two uncoated

bounces off the mirror under test, the typically 45-degree angle of the

mirror under test actually reflects more light than at normal

incidence due to polarization effects, so this makes testing somewhat

easier than other

arrangements with two bounces off an uncoated mirror (such as testing a

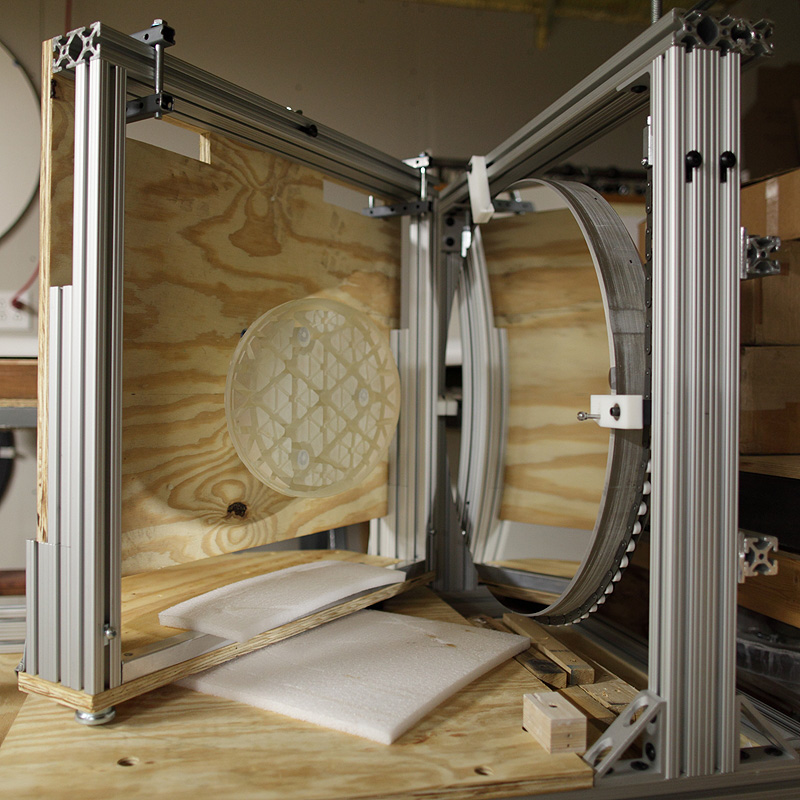

Cassegrain system with an uncoated secondary mirror).In order to implement this test, we had to build a custom holder for the sphere and the flat under test, and I wanted to allow varying sizes of flat to be tested. The setup is shown above in the larger image, and obviously the coated sphere is on the right. The flat holder can be rotated to face the sphere and then tilted down to horizontal so that larger flats can be placed in easily and safely for testing.

Our first R-C project (with this sphere, others have been done in the past with a long 10" sphere) was a 10.6" cast cellular elliptically-shaped flat. It was already rough-polished, and it was hand figured to well within the specification of 1/4 wave P-V surface error. Most of the surface was far, far better than the specification, in fact. The measurements for the flat were highly repeatable with proper support of the flat. The flat under test is seen above in the larger image. Note that it is tested at the same angle that it will be used at in the telescope. This type of setup makes testing flats in holders quite simple and accurate, too.

Conveniently, the interferometer is potitioned less than 10 feet from the R-C setup. The photo at right makes the distance appear larger because it was taken with a wide-angle lens, but the setup is quite compact because the sphere is quite fast, with an f/2.4 curve and testing done at radius of curvature at f/4.8, approximately. This setup will find a permanent location in my new shop space when it is finished off.

The second project is a thick, 22"-diameter, quartz flat. The mirror is masked down to 19.5" for testing because typically professional projects are oversized so that edge issues are irrelevant. The very heavy flat was carefully move in and out of the flat holder, which was positioned horizontally so that the mirror could be place in it more easily. After it was safely secured, the flat holder was tilted up to veritical and rotated to a 45-degree angle for testing.

This setup proved quite powerful, and this flat has been tested repeatedly to around 1/20th wave. It has some slight curvature (power), but that is not an issue for its intended application as a telescope testing flat.

In the future, this sphere can be used at different angles to test much larger flats, if required, or a larger R-C sphere may be made. I have a thick 48" blank that I someday intend to make into a flat for my own testing use, and it will be tested with this method.

Please check back for future installments of "In the Shop".

Mike Lockwood

Lockwood Custom Optics