10" F/8.75 truss-tube Dobsonian

A while back I traded some refiguring work for a couple of 10" mirrors,

both

of which were figured, but not polished out! I spent quite a few

hours

polishing and figuring both an F/5.5 and an F/8.75 mirror, and then

when

they were finished they proptly were wrapped up, placed in a container

and banished

to

a closet while I finished up other projects (like a 12.5" Cassegrain, a

16.25"

Cass., and many other refigures). This summer I decided I would

finish

this long-focus dob in time for Mars, and I set a self-imposed deadline

of

Sept. 7th, the day before the start of Astrofest 2005 (for a report, click

here).

Well, starting at the beginning of August I got to work. I

decided

to build the major parts of both the F/5.5 and the F/8.75 scopes at the

same

time, thereby saving time. I made the mirror box, mirror cell,

and

diagonal cage for both scopes early in the month. First light for

the

F/8.75 was achieved on Sept. 6th when I viewed some brighter stars in

the

northern sky from my driveway. Through haze, the star test looked

excellent,

and the focal plane was found to be at a spot where all my eyepieces

could

come to focus. For once I didn't have to trim the truss poles!

Anyway, Astrofest 2005 was good for planetary viewing, and I enjoyed

some

excellent views of Mars in the early morning hours. Those views

made

all the work of the scope worthwhile, and I now have a great

appreciation

of the images that can be deliverd by such a long-focus Newtonian.

The

scope has excellent contrast on deep-sky objects, even with the truss

tube construction and no shroud. The cage is fairly well baffled,

and will be even better soon.

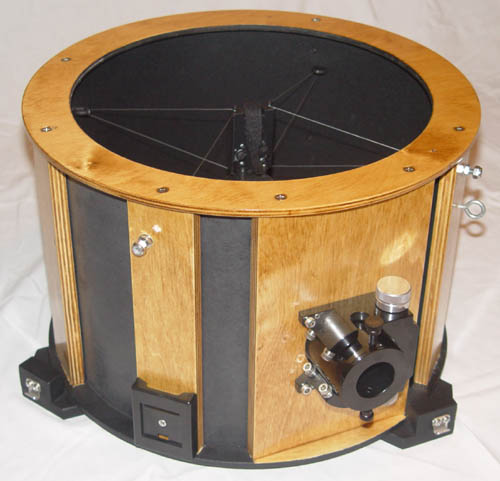

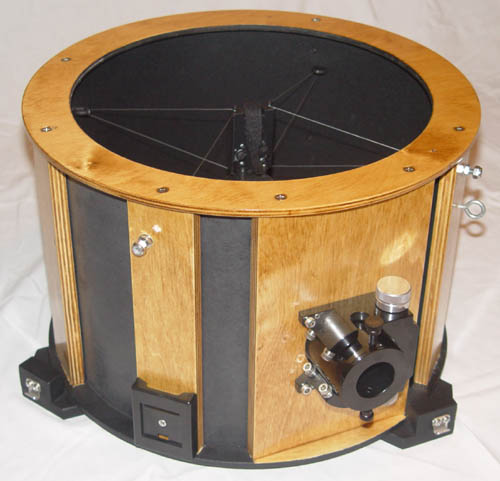

Construction

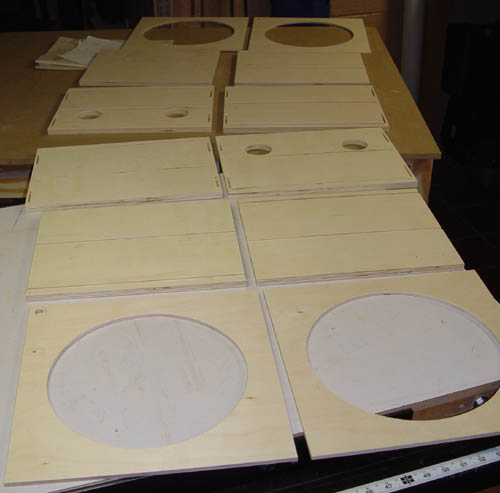

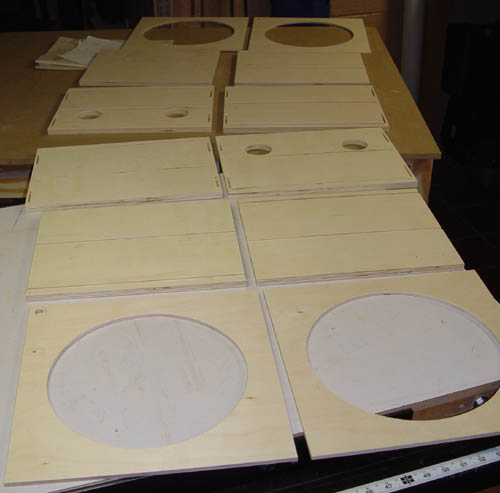

The mirror box for the scopes consisted of 1/2" Baltic Birch (BB)

plywood

sides, and two 1/4" BB baffles, one near the front of the box and one

nearer

the mirror. The parts for both boxes are shown below in the photo

at

left. The right photo shows the holes cut for ventilation fans in

the

top of the box and the dados (slots) cut to receive the baffles.

Biscuit

joinery was used to assemble the box sides, and no fasteners were

needed,

only glue.

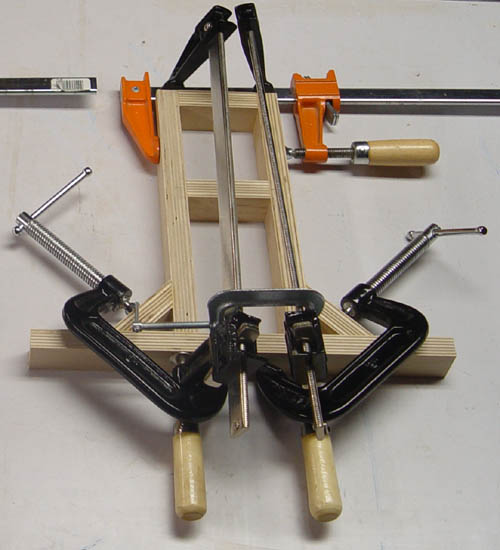

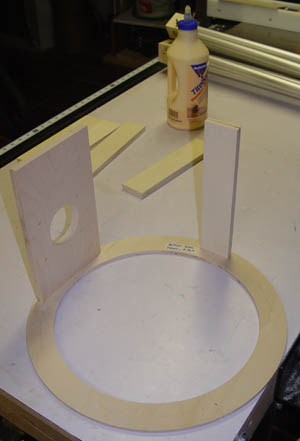

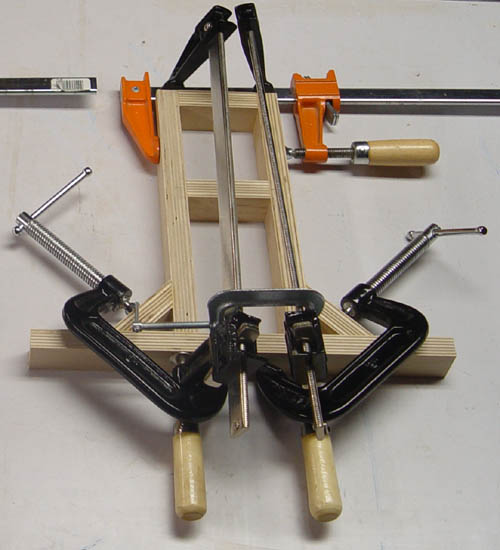

The box was assembled, and the mirror cells and diagonal cages were

also

put together. The cages and mirror cells were assembled with glue

only

first, and then reinforced with a single stainless screw into each

brace.

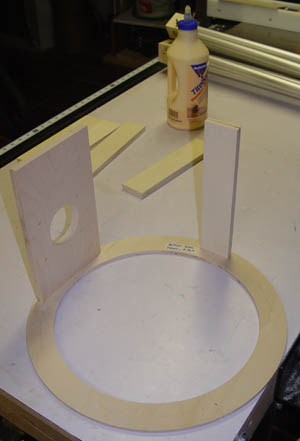

The rings of the cage are 1/4" BB, and the braces and focuser

board

are 1/2" BB. By the way, the glue, TiteBond II, has water cleanup

and

is stronger than the wood when properly used. You don't need to

use

Gorilla Glue to get high strength. (If you try to pull a joint

apart,

you will pull a layer of the plywood off!)

After adding various other parts, the mirror boxes and cages were

stained

and painted. The fans were installed in the box and wired up.

A

plastic cover was added to the back of the mirror cell, to block stray

light

and allow air to only enter from the bottom, encouraging air flow up

and

around the mirror. Below is a photo of the front of the mirror

box

with the mirror cover off, and the back of the mirror with the back

cover

removed and installed.

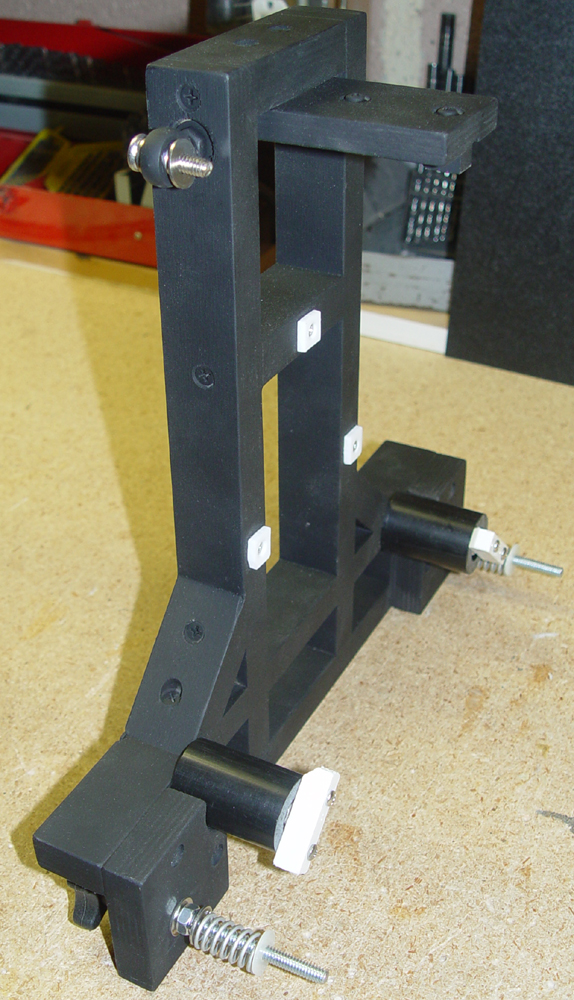

Here's a large photo of the mirror cell without mirror, showing the

ball swivel and the two adjustmend bolts and their associated springs,

etc.

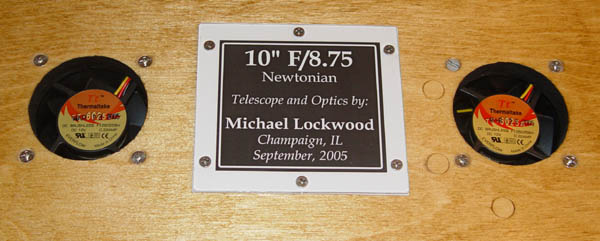

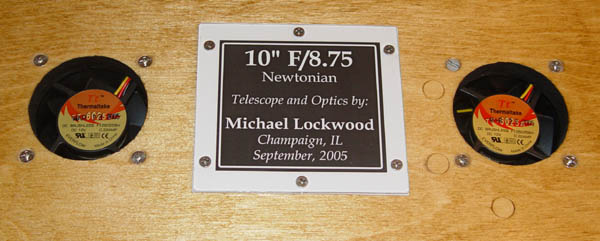

Here is a photo of the front of the box with the cover on. Note

the

dowels and latches that locate the truss poles. The second photo

is

a view of the name plate that I made for the scope from a transparency

printout

sandwiched between a piece of white plastic and a piece of plexiglass.

Yes,

I made it.

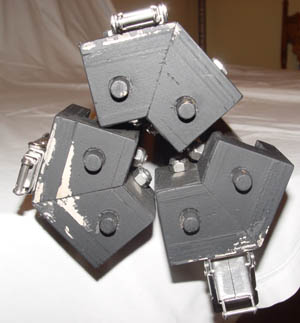

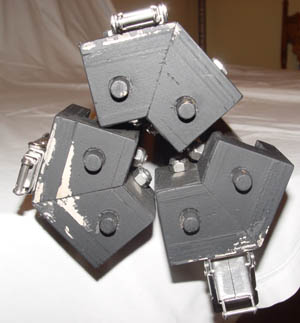

Next, the 6-pole truss assembly was made. This assembly collapses

like

a folding camp chair into a compact clump of poles. When

expanded,

holes or dowels (depending on which end you look at) locate the wooden

"hinges"

, to which the poles are attached, on both the rocker and diagonal

cage.

Then six stainless, spring-loaded latches are snapped and the

scope

is assembled. Here are photos of the poles and closeups of the

"hinges".

The hinges are made of mainly 1/2" BB. First, a long length of

"U"

channel is made from the BB, and then pieces are cut, with one end of

each

piece cut at a 30 angle. When two pieces are glued together, this

forms

the 60 angle that is required for the poles to fold up. This

angle

can be see in the left photo in the second row below. The dowel

pins

are also visible, and these slip into holes in the secondary cage.

The cage is pictured below. Two of the attachment points for the

trusses and the attached "clips" for the latches are visible at the

bottom left and right of the cage. Focuser is a MoonLite single

speed crayford.

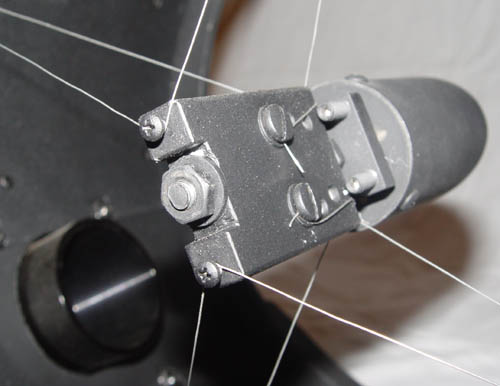

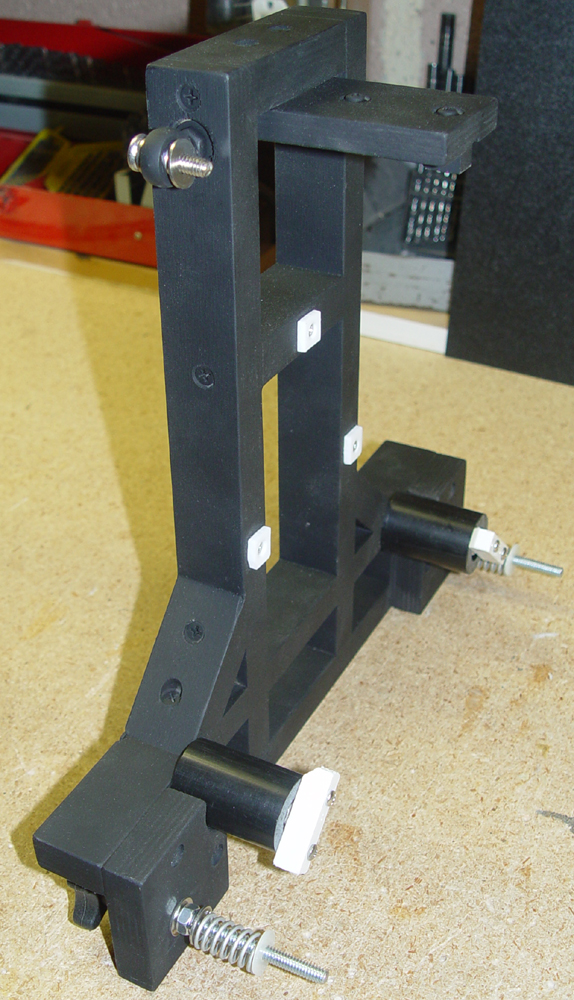

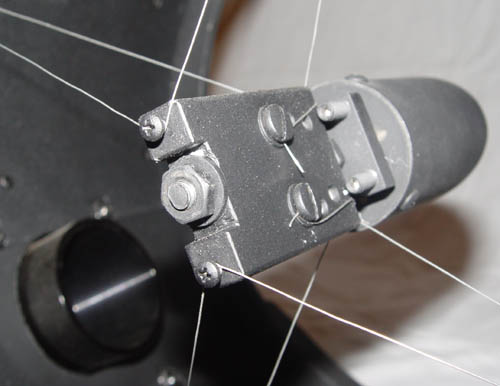

Yes, that's a wire spider. To string the spider, the central hub

was

bolted to a piece of plywood that was temporarily clampted to the top

of

the cage. Below is a photo of the central hub and the jig clamped

in

place.

With the scope able to be assembled, I put it together and made sure

the

truss poles were as close to the ideal length as possible, placing the

focal

plane about 1/4" above the top of the focuser when the focuser is fully

retracted.

Then I assembled the scope and balanced it with a 41mm Panoptic

in

the focuser. This gave me the highest possible balance point,

which

was something like 26" above the bottom of the rocker box. This

is

excellent for an F/8.75 scope. The "wings" were then made to

attach

the bearings to. The "wings" extend the sides of the 10" tall

rocker

box up to the balance point, and are removeable for easier transport.

The

wings are attached to the mirror box with plastic knobs with stainless

bolts

inserted and locked in place, forming handles with stainless threaded

shanks.

Below is a photo of the two wings with the bearings attached, one

turned

upside down. Note the black paint where it is exposed near the

optical

path. The next two photos are of the wings installed on the

mirror

box with three knobs apiece.

With the wings attached, the scope was re-balanced, and the balance

point

moved downward another 3"!! The wings were trimmed and the

bearings

moved down. Now the rocker box could be constructed, and I wanted

it

to come apart for easier handling. (My house is rapidly filling

with

telescopes, so I need things to break down and be compact!) The

base

of the rocker was made from 3/4" BB and four strips of 3/4" BB were

glued

and screwed in a square on top of it to reinfoce it. These strips

also

serve as attachment points for the rocker sides, and the T-nuts that

the

knobs screw into can be seen in the first photo. The rocker sides

were

glued together from ~4" strips of BB, and the curved sides were

attached

with screws. With only two knobs, the sides are still fairly

stiff.

However, later I will probably add a front brace/battery shelf to

stiffen

it up a bit. In any event, without a brace tracking at 450x is no

problem.

Below is a photo of the assembled rocker, with a couple of knobs

pictured

as well.

At last, it was time to assemble the scope. Here's a photo of it

set

up in my house. It is tall enough to require a good step-stool

(zenith

eyepiece height 7'+), but there is something strangely satisfying about

finally

having a scope that requires more than just a few inches for me to view

through

it. (My 16" F/4 requires about a 6" step when I point it at the

zenith

when it's sitting on my equatorial platform.) In the photo the

white

sheet is covering the 12.5" Cassegrain parts. Clearly I have too

many

scopes.

All parts (excluding bearings) are stained with Minwax "Golden Oak"

stain.

The bearings are a "dark walnut" stain by another company whose

name

eludes me. All wood parts are finished with two or three coats of

Minwax

fast-drying gloss polyurethane.

Here are a couple of photos (courtesy of Mike Conron) of the scope set

up at Astrofest

2005. The second photo shows the QuickFinder installed on the

secondary cage, the yellow flashlight counterweight that is attached

when light eyepieces are being used, and the central baffle/vibration

dampener. (The 30" F/3.8 is in the trailer behind the scope in

the photo.)

For my thoughts

on the scope, see my Astrofest

2005 report. What I will say here is

this - a friend and I compared his 12.5" F/5 Starmaster with

excellent

Zambuto mirror with my 10" scope while viewing Mars. Both scopes

had

equilibrated and were in good collimation. Comparing the view,

both

yielded excellent high-power images, but my scope had a bit more

contrast

and showed a bit more detail on the Martian surface.

Additionally,

the edge of the planet seemed a bit sharper to me. I attribute

these

differences mainly to the wire spider and smaller obstruction.

This telescope has altered my plans as to what to build next (besides

finishing

the 10" F/5.5). While I had planned to try an unobstructed

design,

I think I might shelve that project in lieu of making a larger moderate

focal-length

scope. By moderate I mean F/5. By bigger, I mean 20" or

22",

and still manageable by one person.