Building an open-tubed 12.5" F/12.5 Classical Cassegrain

By Michael E. Lockwood

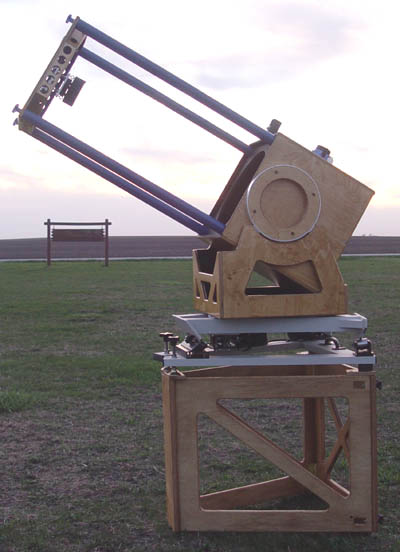

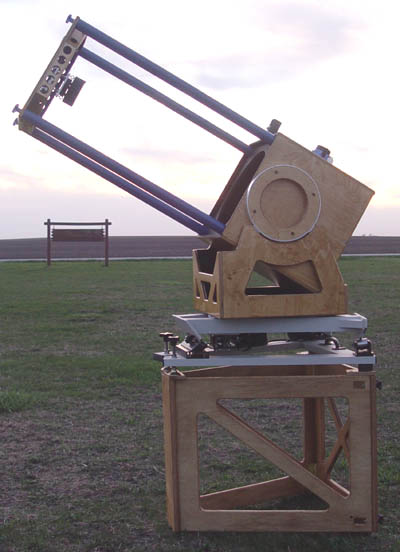

Figure 1: Telescope,

equatorial platform, and support platform,

waiting for darkness in the fields of Illinois.

Introduction

I've enjoyed watching the sky ever since I was a child, growing up in

the dark woods of northern Michigan. My father has always been a

builder of things (houses, hobby projects, etc.), and I am the same way

- I am always creating something. So, building telescopes

naturally grew out of my love of the sky. With some help, I built

three telescopes in high school, and used them quite a bit. After

finishing college and grad school and some house rennovations, in early

2002 I decided to finish a

mirror making project that I had started in 1989. With a little

advise, it came out quite well. My first

mirror, an 8" F/3.9, is something that I will never sell.

Fast forward three years - after making many Newtonian telescopes and

after grinding, polishing

and figuring about 20 parabolic primary mirrors (by hand), Mike Conron

and I made a 30" F/3.8 mirror with the aid of his grinding

machine. We did the final

figuring by hand. I had figured some very good fast mirrors

before, so I ended up taking charge of the figuring of this very big,

very fast mirror.

(Mike C. tended the machine through virtually all the grinding

and

polishing.) We put in a lot of time, and had a lot of fun (not to

mention

a few beers!), and when that mirror was done I was thrilled. (See

the end of the article for a link to my web site, which has a section

on the 30".)

But what could be the next challenging project after making such a big,

fast mirror?

My friend decided to thank me for the figuring help by giving me a

full-thickness, Pyrex, perforated 12.5" F/4.2 Cassegrain primary that

needed refiguring. That was the start of the project. Up to

that point, I'd only seen one amateur-made Cass, and one non-commercial

cass made by a professional optician, so I figured it must be a

challenging project to get both the

optics and the mechanics right.

I like a challenge.

Additionally, this type/size of long focus telescope can be used with

your feet firmly planted on the ground (no ladders), and often viewing

can

be done from a VERY comfortable seated position. More detail can

be

seen when you're comfortable. Putting the whole scope on a

tracking

platform would further increase viewing enjoyment, and would make

waiting

for that second of steady seeing much more bearable. The price

for

the convenience of the viewing position is that you must make a highly

precise convex mirror.

Cassegrains do have disadvantages - they can be difficult to baffle,

collimation requires a laser collimator and practice, there are more

optical surfaces to scatter light, and their mechanical construction is

not as easy as a Newtonian. I chose not to worry about the

disadvantages, and focus on the positive aspects of the design. I

wanted to use the scope and judge it for myself at that point, not

before.

After a lesson in the equations that define the design of a Cassegrain

telescope, I wrote a short, simple computer program to calculate

several designs with different focal ratios. Taking into account

the fact

that I wanted the focuser to sit on top of the mirror box, rather than

behind

the primary, I settled on a design with a focal ratio of F/12.5, about

as

fast as was practical given the primary's focal ratio (which I wasn't

about

to change!), a secondary of 4" in diameter, and a 32% obstruction

ratio.

The fully illuminated field has a diameter of 0.6". A 1.53"

elliptical

tertiary mirror, the same type as is used as a secondary mirror in a

Newtonian,

was located just in front of the primary mirror, and sent the light

path

out the top of the mirror box to the focuser. That is, instead of the light passing through the

hole in the primary mirror, it is reflected upward into a focuser

placed on top of the mirror box. This places the eyepiece

in the comfortable viewing position.

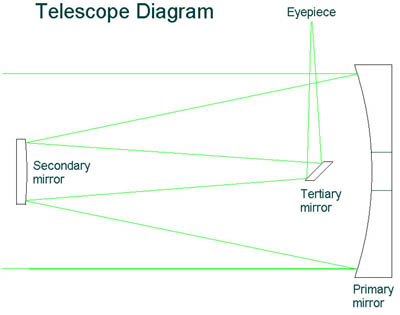

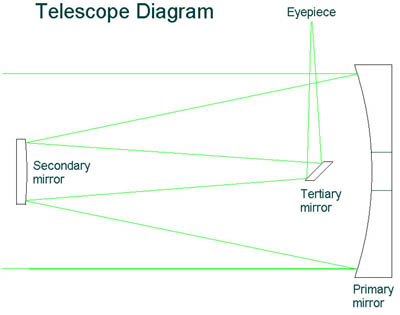

Figure 2: Telescope diagram

- green lines represent light path.

Primary mirror is concave, secondary mirror is convex, tertiary

mirror is flat. Not to scale.

Another advantage of the Cassegrain design is the long focal length -

high

magnification is possible with longer focal length eyepieces with more

eye

relief, and Jupiter's moons are disks, not the "comets" that they

become

in a fast Newtonian. (Many do not realize that the performance of

a perfectly collimated F/4.5 Newtonian will be limited by coma if an

object,

such as a planet, is not well-centered in the field of view.)

Magnifications

of upwards of 400x are achievable with a 9mm Nagler. On the other

hand,

A 41mm Panoptic provides 96x, which is low enough to make finding

objects

fairly easy, and viewing the entire moon possible. No vignetting

is

noticeable with this eyepiece, even with its enormous field stop!

So, here's a quick summary of why I did the project:

1) Challenge of fabricating a different

(non-Newtonian) optical system

2) Lack of amateur-made Cassegrains

3) Convenient viewing position

4) Compact telescope

5) Long focus - high magnification is easy, little coma

6) I already had a primary mirror blank that only needed

refiguring

My goals were

1) High optical quality, minimal spider diffraction

2) Ease of transport and assembly/disassembly, and

3) A unique telescope that might inspire others to make a Cassegrain.

At some point you might also wonder what tools I used. Most are

fairly standard woodworking tools. Here's a list of the power

tools:

10" tablesaw, 12" chop saw, router, jigsaw, drill,

drill press, orbital sander, biscuit jointer.

(I don't have a lathe or mill....... yet!)

Optical Fabrication

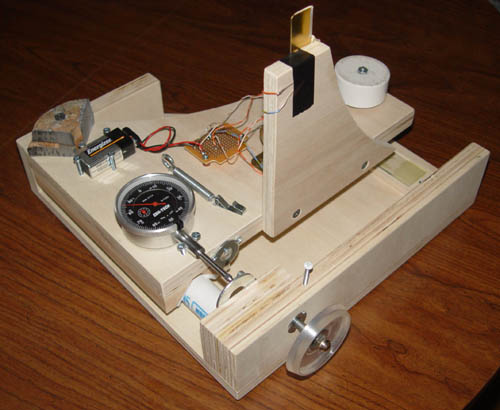

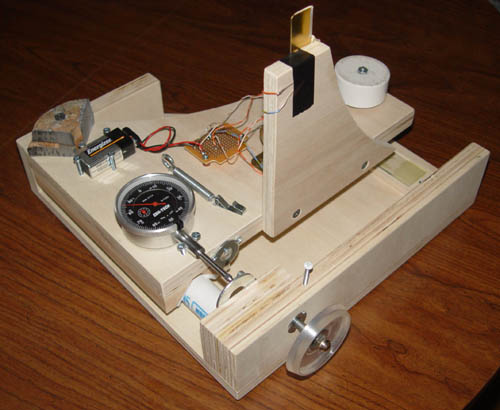

I'm an amateur optician,

working by hand. I use

the Foucault test

to test concave mirrors.

The tester was built in an

evening, and costs $20 or so, including a $10 dial indicator.

Nothing fancy here. It is pictured below. The "knife edge"

is actually a 1/16" x 1" piece of brass stock a few inches long.

The edge is prepared with careful filing and lapping against a ground

glass plate (see Texereau's "How to Make a Telescope" for this

procedure) to get a very straight, slightly rounded edge. Such a

tester, with careful use, is capable of testing optics to 1/10th wave

wavefront accuracy, or about a millionth of an inch on the

glass. This is my third Foucault tester.

Figure 3: A slitless

Foucault tester for testing concave mirrors.

This tester was used to measure the shape, or "figure" of the primary

mirror and the test plate for the secondary mirror (more on this below).

The primary mirror refiguring was no different than a normal parabolic

mirror, except that it had a hole in the center! The subdiameter

lap that I made was made just large enough that it could be pressed

between

the hole and the edge of the mirror. At the beginning of a

figuring

spell, the lap was used gently after the press until it no longer

grabbed

when passing over the central hole. The severely undercorrected

outer

zones were corrected gradually, and the mirror was soon done with a

smooth

figure accurate to significantly better than 1/10th wave wavefront

error, according to my measurements.

Focault testing

was done with a six-zone Couder mask.

Here's

a photo of the coating being stripped off the primary mirror before

refiguring, and of the

subdiameter

lap being pressed into contact.

Figure 4a: Old coating

being stripped. Masking tape dam keeps the

chemicals from running off the sides, or down the hole.

Figure 4b: Subdiameter lap

being pressed under water jug and weight.

The secondary was the critical

component in the scope. It had to

have the right curvature so that the focal plane was located in the

proper place. This is important - moving the secondary in and out

can move the focal plane around and give more or less back focus if

necessary, but one should not deviate too far from the ideal spacing.

Moving the

secondary too far inward towards the primary results in

undercorrection.

Moving it too far out results in overcorrection. For this

adjustment,

1/8" of change in the spacing makes a big difference in star testing

results. The moral of the story is, get the secondary curvature

right, or you will have to redesign your scope!

The secondary mirror and grinding tool both began as 4" Pyrex

blanks.

With grinding, gradually one becomes concave (the test plate), and the

other convex (the secondary mirror).

Because I wanted to make more Cassegrain secondaries in the

future and other small mirrors, too, I built a small turntable that I

could sit comfortably at

while grinding or polishing. Cost was under $150. A

geared-down 1/3 hp DC motor drives

the turntable via a belt. The motor is powered via a variable

transformer

(a Variac) and a full-bridge rectifier, which converts the 120VAC from

the wall to anywhere from 0 to about 90VDC. I wired it up

myself. This homemade speed controller

spins the turntable anywhere from 0 to about 250 RPM. (I plan to

add

a driven arm to this machine very soon, so it can polish mirrors up to

about

13" in diameter for me while I watch!) As pictured, though, it

has a manual overarm. I hold onto the arm and move it back and

forth while the turntable turns the work. The top of the machine

is a

piece of formica-covered countertop that I had on hand, and the red

splash

pan is a water tub for farm animals, purchased for a few dollars at

Farm

and Fleet.

Figure 5: The turntable,

with manual overarm, polishing a 5" mirror.

All equipment on top of the machine is vital!

I ground the secondary mirror and test plate from 120 grit Carbo down

to 5 micron Aluminum Oxide, measuring their curvatures frequently with

a crude spherometer made from a pulley, some ball bearings, and an

inexpensive dial indicator.

The concave tool later became a test plate, a polished optical surface

that is figured to a concave hyperboloid that perfectly matches the

convex

hyperboloid that the secondary will become. Below is a photo of

the spherometer, sitting on a fairly flat surplus optical window,

zeroed and ready for measurement of the curvature of mirrors. The

large bolt is tightened by hand, and holds the dial indicator

stationary in the bore of the pulley. To the right are both 4"

and 5" test plates and secondary mirrors. The 4" became the

secondary for this telescope. (The 5" secondary later went into

our club's 16.25" F/12.5 Cassegrain - it was another large project in

it's own right. See my web site link at the end of the article

for more info on that scope.)

Figure 6: Spherometer being

zeroed, future 4" and 5" secondary

mirrors and test plates. (The 5" was for another telescope.)

The concave test plate

can be tested using the Foucault test, and figured just like a small

primary

mirror, however it has several times the correction of a parabola of

comparable

size and focal ratio. (For mirror makers, this one had about

four

times the correction of a 4" F/6 parabola - not too bad.) I

finished

figuring the test plate in a few evenings of work, and I noted that I

had

a small, slightly depressed ring just inside the edge of the mirror.

This

would be important later, when I was trying to make the secondary

mirror

match the test plate to within a millionth of an inch.

Once the test plate was done, I had to polish the secondary mirror out

without having the curve drift too far from the curvature of the

already-finished test plate. Using the machine, the secondary

polished out less convex than it should have been, so I had to use a

special lap to wear down the

outer part of the mirror until the curvatures matched approximately.

The

lap had some of the pitch carved out from the center, so that the edge

would

wear more than the center, thereby making it more convex.

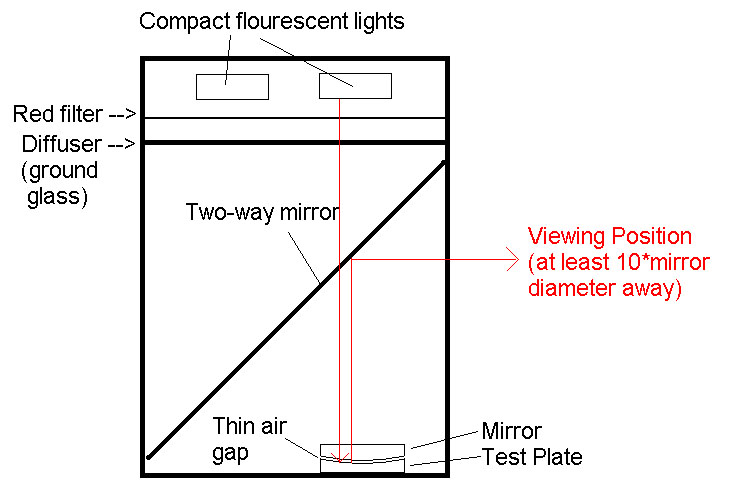

After polishing sessions, the curvature of the secondary was compared

to that of the test plate

(both polished) using a simple Newton interferometer, which consists of

a few compact fluorescent lights, a diffuser screen, a red filter (for

lighting effects), and

a

two way mirror. This is homemade gear, costing about $40 to build

from plywood. It is NOT an expensive

commercial

interferometer. To perform a test to see how the mirror and test

plate fit, the mirror

and test plate are cleaned, and then placed in contact with each other

under

the interferometer. They settle into intimate contact if they

are

clean, separated by an air gap only a few wavelengths of light thick,

or

about

100 millionths of an inch. (That's why they must be clean!)

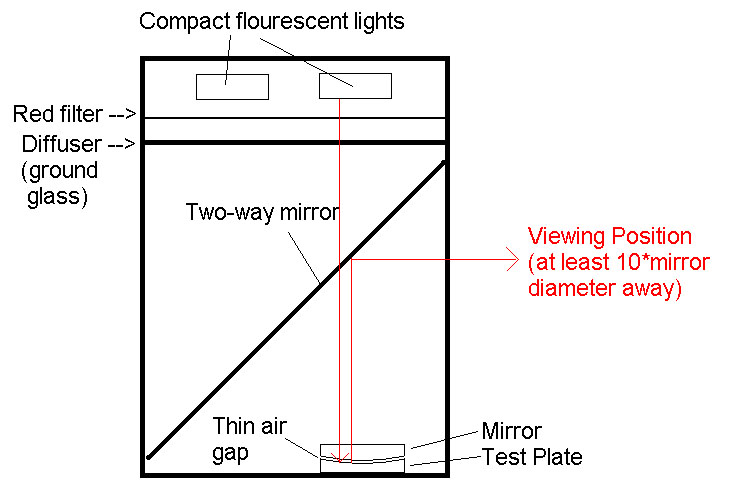

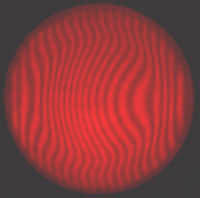

Figure 7: Diagram of simple

Newton interferometer. Convex mirror

sits on top of concave test plate, separated by a thin air gap.

The simple setup produces a fairly good source of diffused

monochromatic

light, which allows the differences between the secondary and test

plate to be observed in terms of interference "fringes", the dark bands

seen between bands of

red below. The spacing between each dark fringe represents 1/2

wave

of surface error (about 14 millionths of an inch for the red light used

here),

which is one wave of wavefront error. The fringes are viewed from

several feet away to avoid parallax errors, which distort the fringes

if you view them from too close to the tester.

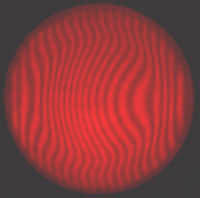

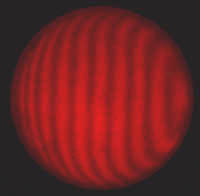

In a nutshell, curved fringes mean there is work still to be done -

they

mean that the mirror and test plate don't match exactly. The

appearances of the

fringes

themselves means that the top piece is "tilted" with respect to the

bottom

piece. It is easy to observe the "squiggles" and curves in the

fringes.

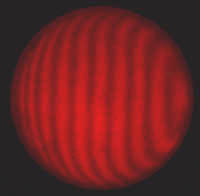

In the photos below, where the lines curving to the right

represent

a high spot. Thus, in the first photo, a high ring exists at

approximately

the 70% zone, that is, 70% of the way from the center to the edge.

(This

is normal in figuring a Cassegrian secondary.) In the second

photo,

the outer areas are high. Photos are taken at a distance with a

digital camera - this is exactly how it looks to your eye when looking

into the tester.

Figures 8a, 8b: Photos of

interference fringes during testing.

Fringes curving to the right indicate high spots.

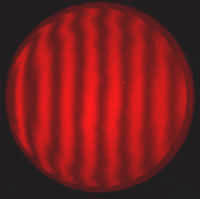

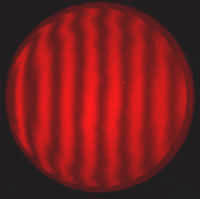

Figure 8c: Interference

test for finished mirror.

The fringes gradually get straighter, and the final result is shown in

Figure 7c. The larger "wiggle" in the fringes about

3/8"

inside the edge is due to a depression on the test plate, not the

secondary,

so the figure of the mirror turned out quite well. A perfect

mirror/test plate

match would show perfectly straight fringes. The test plate is

safely packed away in a closet, ready for use if I

ever need a secondary mirror with the same specifications.

With both mirrors finished, the optics were off to L&L Optical

Services for coating with enhanced aluminum. For this type of

Cassegrain, which has three mirrors, having 95% reflectivity (enhanced

alumimum) on each

optical surface provides about 86% light throughput, versus 70%

throughput for three mirrors with

89% reflectivity (standard aluminum). That's a big (almost 20%)

difference, and worth the extra cost.

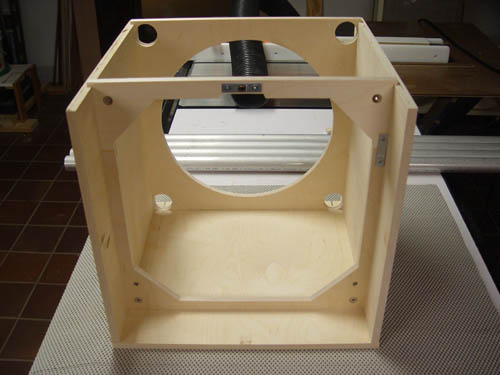

Telescope Construction

While my primary goals for this telescope were high optical quality and

a convenient viewing position, I also wanted a telescope that I could

easily disassemble, and which would not take up too much space.

The solution for me was an open tube with oversized tubes at the

four corners of the mirror box.

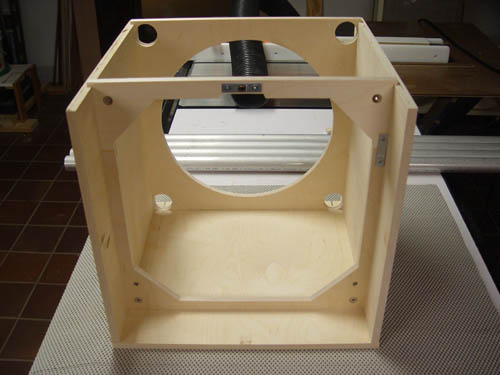

The mirror box was made of 1/2" baltic birch plywood. It features

two baffles, one each near the top (front) and bottom of the box, which

fit in

dadoes (slots) that are cut in the inside of the box sides. The

box sides are joined at the corners with biscuit joints - slots are cut

in the wood which accept small wooden "biscuits". These biscuits

align

the joint and strengthen it. When glued with good quality wood

glue, the biscuits and dadoes form a very strong box with no other

fasteners required. This means no screw or nail holes to patch.

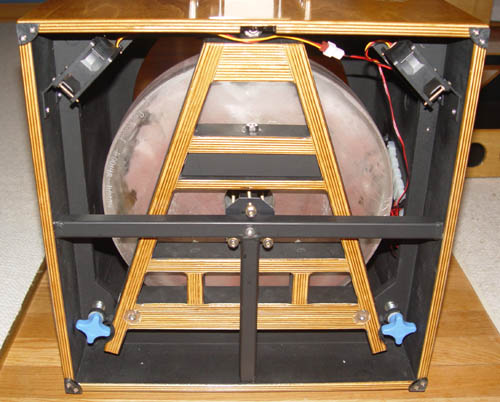

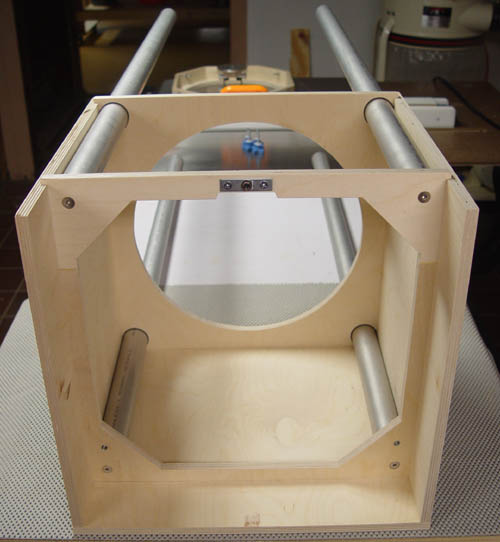

Here's a photo of the mirror box, viewed from the rear, assembled

without glue to check the

fit of the parts. Note the holes in the front baffle to

accomodate the 1.5" diameter aluminum poles. The edges of

the holes don't line up exactly with the insides of the box - this

bends the poles slightly when the scope is assembled, and thereby

creating a

stiffer tube structure. The poles are stuffed with

styrofoam

peanuts to damp vibration, and have threaded inserts in each end.

The threaded inserts screw on to four bolts inserted in the the

back baffle in the mirror box. The heads of the bolts are visible

at the four corners of the back baffle (nearest in this photo).

Figure 9a: Mirror

box partially assembled. Top of box has been removed.

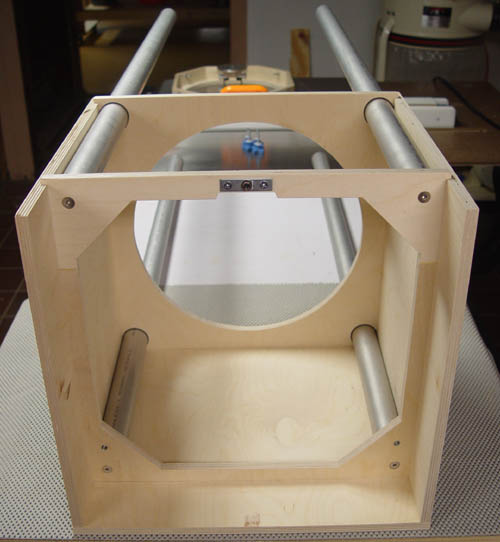

Here is another photo of the box, again without the top, with the poles

inserted and threaded onto the bolts. The metal bracket at the

top of the back baffle serves to reinforce the attachment point for the

mirror cell.

Figure 9b: Mirror

box partially assembled. Poles installed.

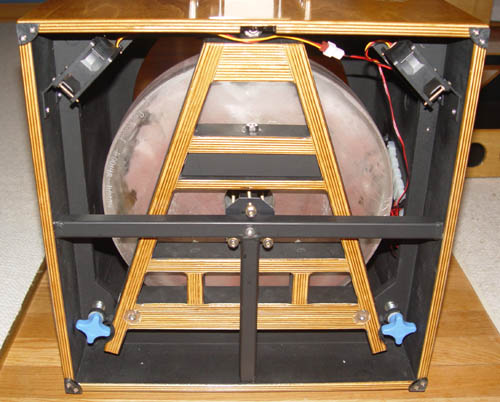

The mirror cell was made mostly of 3/4" strips of baltic birch plywood,

laminated together in places for strength. Its triangular frame

is

attached to the back baffle in the mirror box (above) with a bolt and a

type

of rod end that allows a bolt passing through it to pivot with very

little

mechanical slop. The bottom two attachment points also employ the

same

part of rod end, but these points are movable to allow for collimation.

Threaded knobs allow tweaking of the primary collimation at the

eyepiece, using a star.

The primary mirror is supported with a four-point mirror cell. A

photo of the nearly finished, painted mirror cell is below. The

top two contact points (white plastic squares) are mounted on a piece

of aluminum tubing which is supported at the center - this is

effectively a teeter-totter. The bottom two points are fixed.

This supports the full-thickness mirror enough to prevent

detectable flexure of the primary mirror. The two L-brackets that

support the bottom of the mirror were later replaced posts made of 1.5"

diameter Nylon. A teflon contact point was added to the top

bracket, and PVC mirror clips were fitted to all three brackets to keep

the mirror in the cell. In this type of cell, the mirror clips

move with the mirror, so the mirror need not have lots of room to

rattle around.

Figure 10: Mirror

cell. 4-pt. support is enough for the full-thickness primary.

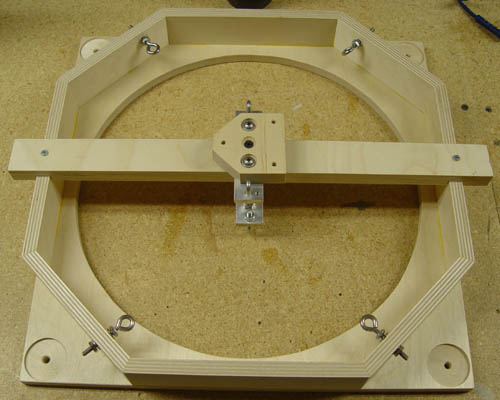

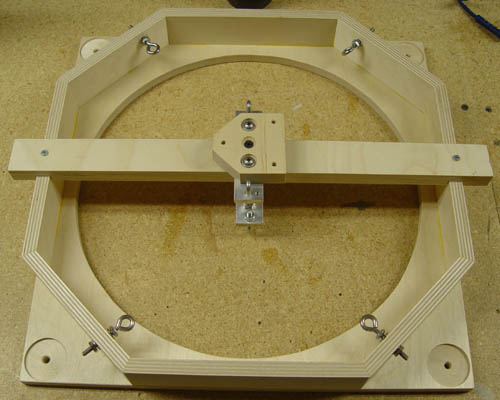

My goals for the secondary cage were light weight, low wind profile,

and minimal diffraction caused by the secondary support. This

meant using a spider that was made of thin wire, something I had never

seen done with a Cassegrain telescope. Additionally, the spider

attachment points on the central hub are offset to resist rotational

vibration of the secondary. (The

offset spider concept was introduced decades ago in Texereau's book,

"How to Make a Telescope"; still, few people realize its

advantage.)

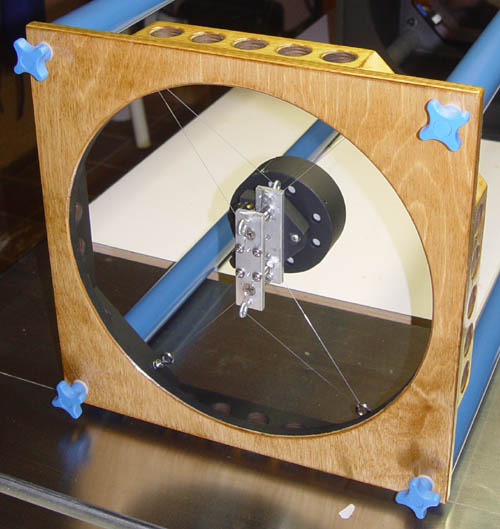

For the secondary cage, I chose to make a square front board with a

circular

hole to define the telescope aperture, reinforced with an octagonal

frame that would serve to anchor the spider. The four

poles attach at the corner of the squares, sitting in recessed

holes.

The secondary cage assembly was glued together, and this proved

fairly

complicated. Here's a picture while the glue dried.

Figure 11: Assembly of

secondary cage. You can never have too many clamps....

The forest of clamps was removed, and holes were later drilled in the

octagonal frame to lighten it and allow wind to pass through.

Before this, though, the holes for the four stainless eye bolts

that anchor the spider were drilled. As the spider is of the

offset variety, these holes are not equally spaced around the octagon.

The central hub consisted of two 3.5" x 1" x 0.25" aluminum bar,

connected by two stainless bolts which were threaded all the way to the

countersunk head. The bars were locked onto the bolts with nuts.

Four small screws serve as anchors for the ends of the two pieces

of wire that form the spider. A piece of baltic birch is attached

to the aluminum bar. Three adjustment screws pass through the

wood and secure the aluminum secondary holder. Here is a closeup of

the central hub. The front is at the bottom.

Figure 12: Central

hub of the wire spider. Secondary mirror

attaches to wood block at top.

To string the spider, a jig was made consisting of one strip of baltic

birch, with holes drilled so that the central hub could be

securely fastened to it. Stainless steel wire, 0.015" thick, was

secured under one screw and washer on the front of the central hub

assembly. The screw was tightened securely, and the wire was

threaded through one of the eye bolts on the front of the central

hub. It then passed through an eye bolt on the secondary cage

(wrapping completely around it once),

back to the central hub and through the eyebolt on the back side

of the central hub, through another eye bolt on the secondary

cage, and finally through the eyebolt on the back of the central

hub. The wire was pulled fairly tight, and secured under another

screw and washer. This formed the bottom two legs of the offset

wire spider. The sequence was repeated for the top two legs,

with another piece of wire. The wire was then de-tentioned by

loosening

the eye bolts on the secondary cage, the jig removed, and the wire

re-tightened.

Thus, the spider was completed. Here's a photo of the

secondary

cage, central hub, and spider jig before stringing.

Figure 13: Secondary cage

and spider stringing jig. Ready for wire.

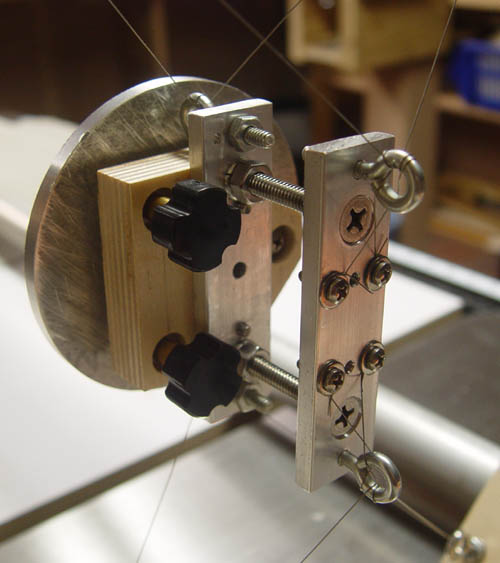

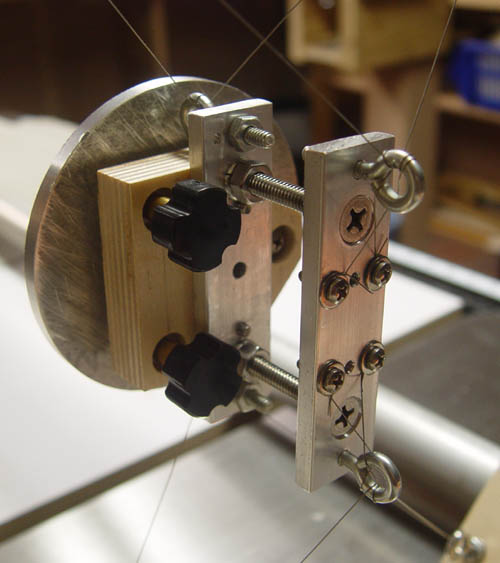

The next photo shows a closeup view of how the wire was wound and

secured on the central hub. Where the wire passed through the

screw

eyes on the cage (seen in the photo above), it was wrapped once around

the eye before going back to the hub. The two black knobs are

used to adjust the tilt of the secondary holder. Compressible

rubber washers are placed between the aluminum disk seen in the photo,

which is part of the secondary holder, and the piece of wood.

Later, a strip of aluminum was bent around

the aluminum disk, a lip was bent over on one side, and it was secured

to

the disk with screws. The secondary sits inside this assembly,

with

polyester batting behind it to press it gently against the lip, much as

is done with many secondary holders in Newtonian telescopes.

Figure 14: Closeup of

central hub, suspended by wire spider.

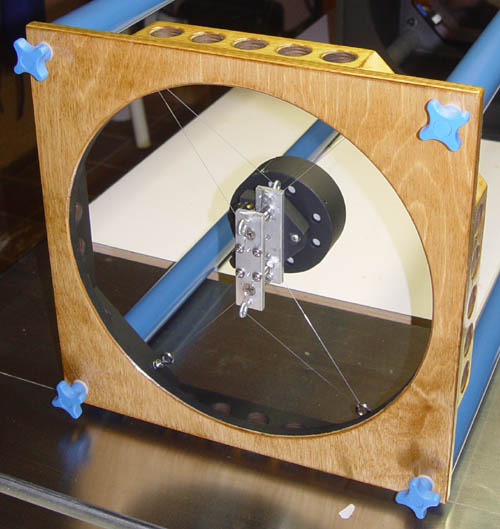

Finally, here's a photo of the finished secondary cage, complete with

painted secondary holder, and a painted and stained cage. The

blue

knobs attach the poles (by threading into the threaded inserts in the

tubes),

to which the cage is attached in the photo. Note holes in the

sides

for weight reduction.

Figure 15: Finished

secondary cage. Blue knobs thread into inserts in

the poles. Unpainted aluminum in hub is not visible to the

optics.

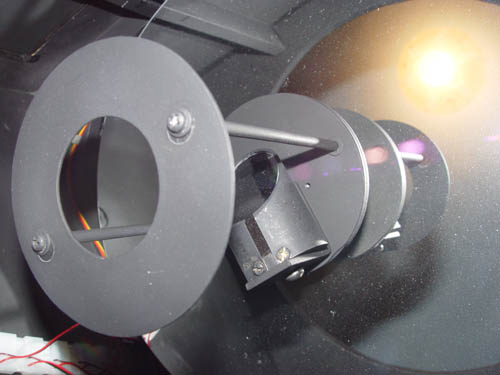

For the tertiary mirror holder, I wrapped a thin piece of aluminum

sheet

around a 1.5" dowel, and used a chop saw to cut it off at a 45-degree

angle. The aluminum was slid down the dowel a little bit, and a

lip was created around the 45-degree hole. This would hold the

tertiary mirror in. A metal plug was inserted into the other end

of the aluminum, and a bolt passed through and angle bracked and into

the plug, securing it to the tertiary assembly.

The tertiary assembly tilt is adjusted via sections of threaded

rod

that can be accessed from the rear of the telescope. These act as

push bolts, and there is a central pull bolt attached to the tertiary

holder assembly. (Tyipcally,

this

mirror is quite stable and needs no adjustment.) A photo of the

tertiary

holder is shown below, installed in the scope, in front of the slightly

dusty

primary. The round disk attached to the two standoffs is a ring

baffle,

which blocks stray light from reaching the tertiary. This is much

simpler than a traditional round baffle, and is much easier to

implement. A classic "pipe" type baffle would probably work

slightly better, but its inside must be carefully baffled to prevent

reflections at grazing incidence. For my use, this baffle works

well.

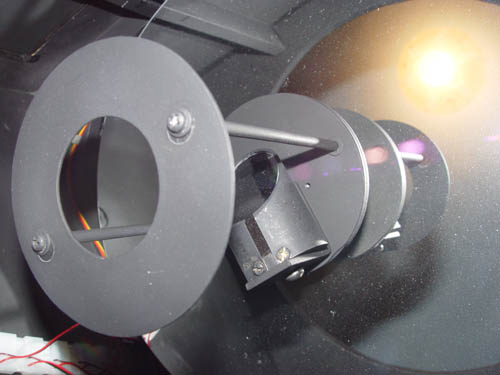

Figure 16: Tertiary

mirror in 45-degree holder. Ring baffle is to

the left. Light from the secondary passes through the hole in the

ring. Disk behind tertiary is plexiglass, painted black.

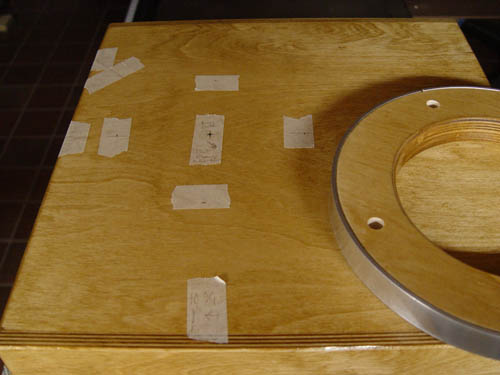

The various wooden parts of the telescope were stained and

polyurethaned. Internal parts were painted Krylon Ultra-Flat

Black. Teflon and formica were installed on the rocker box, and

the side bearings were bolted on the mirror box. The side

bearings are 1" thick, composed of two thicknesses

of 1/2" baltic birch. 1/8" x 1" aluminum bar stock was bent

around

the outside edge with waterproof glue underneath. Screws secure

the

bearing at various points around the circle. The glue fills in

any

gaps under the aluminum, filling in any slight void and eliminating any

tendency

of the scope to "bounce" when move small amounts in elevation.

Below

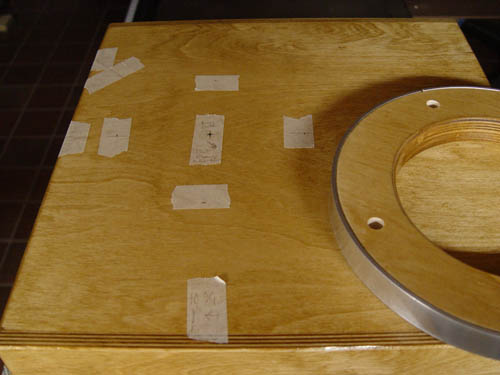

the masking tape layout is shown for the side bearings, with the

balance

point of the scope marked. Four bolts secured each side bearing.

Figure 17: Marking the

balance point and installing the side bearings

The focuser is a blue-anodized 2" Crayford model from Moonlite.

It sits on top of a wooden platform on top of the mirror box. It

is smooth in operation, and the blue color matches the blue of the

tubes and the collimation knobs. This blue color goes well

with the golden color of the woodwork. The focuser can be seen in

the photos of the assembled scope below.

First Light

First light happenned in my driveway near the beginning of April of

2005. I set the rocker box on a piece of plywood, which was

placed directly on the concrete of my driveway. I knelt to look

in the eyepiece, and located a bright, poorly collimated image of the

waxing moon. Two friends looked too. I realized it was time

for some serious collimation work, installation of light baffles, and a

folding platform to privide that convenient viewing position that I was

so fond of. The equatorial platform arrived soon afterward, so it

was time to build a support platform for it.

Folding Platform

The folding platform was my idea and creation. It folds up (to

about 24" x 20" x 5") for

easy storage. When unfolded, two threaded knobs are installed,

locking the

sides

together. It is triangular to match the shape of the equatorial

platform

that I bought from Tom Osypowski; with the equatorial platform sitting

on

top of it, it is extremely rigid, and does not vibrate much at all.

Here are

photos

of the platform being unfolded. Note the selective removal of

wood with bracing remaining intact.

Figures 18a, 18b: Support

platform folded, and partially unfolded.

Figure 18c: Support

platform with locking knobs installed.

The space inside the platform is a very convenient place to place the

17

amp-hour battery (a "jump start" power pack) that I use to power my

telescopes. It sits completely out

of

the way, and no one can trip over the cords!

Pole Case

While I was in a building mood, I made a case for the four poles.

It

was made of 1/4" and 1/2" Baltic Birch. I made the box, and glued

the

sides to both the top and bottom. Then I cut the lid off with my

tablesaw,

ensuring a perfect fit of the lid. Here's a photo of the tubes in

the

box, complete with some strips of weatherstripping to keep the poles

from

rattling. (The end of the poles that goes inside the mirror box

is

painted flat black, the rest is Rust-Oleum Royal Blue.)

Figure 19: Pole

storage box, poles inside.

Ventilation

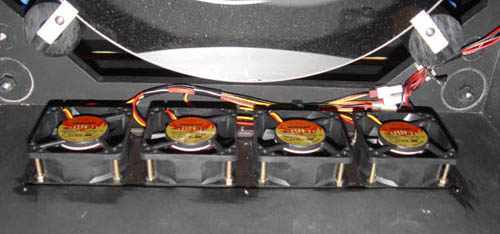

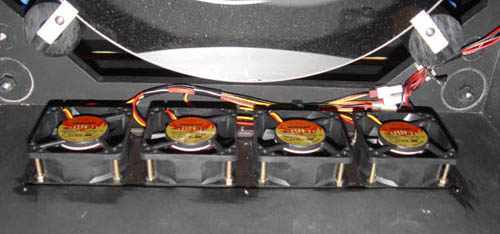

The full thickness primary mirror needs cooling. There is no

alternative.

So, I added six 60mm, double-ball-bearing 12V fans to the

mirror

box. Four push air up across the primary from the bottom, and out

through

doors in the top of the mirror box. Two fans move air across the

back

of

the mirror from the top corners of the mirror box. Here's a photo

of

the fans blowing across the primary:

Figure 20: Ventilation fans

for front of primary mirror.

Here's a photo of the back of the mirror box, showing the tertiary

support

framework (T-shaped square tubing), tertiary adjustments near the

center,

and the two fans in the upper corners:

Figure 21: Back

of mirror box. Ventilation fans at upper right and

left. Tertiary adjustments at center. T-shaped structure is

the

tertiary support, made of steel tubing. Blue knobs are for primary

collimation. Back of box is open for better ventilation.

The six fans result in much faster equilibration, and improved images

during

cooling. No vibration is noted from the fans at high power.

I have experimented with a fan blowing on the secondary from below, but

I haven't concluded whether or not it is beneficial.

Collimation

After adding flocking paper to the focuser (which resulted in the

single

largest increase in contrast of any step that I took) prevented

me from

inserting

my 2" laser collimator all the way into the focuser. So, I now

use

a 1.25" collimator. First, the tertiary is

aligned

to place the laser in the center of the secondary (this usually does

not

require adjustment). Next, the secondary mirror is adjusted so

that

the reflection of the laser returns to exactly where it originated.

Finally,

the primary mirror is adjusted while viewing a star in the eyepiece, to

eliminate

coma. The two blue knobs in the picture above are the primary

collimation adjustments.

That's all there is to it. I can have the scope collimated in a

few minutes, provided I can find a star to align the primary

with. (A barlowed laser would probably allow daylight collimation

of all the components, but some tweaking of the primary might be needed

once it got dark. I hope to try this soon)

Performance

The performance of this telescope has exceeded my expectations.

With

a 32% obstruction ratio, I expected planetary detail to be washed out,

and

reduced from what I was used to seeing in my Newtonians. I was

wrong,

especially after a little collimation practice!

Planetary detail was excellent. Saturn was sharp at 450x when the

seeing

permitted. Jupiter showed numerous bands and subtle detail.

I

could discern color in one of Jupiter's moons as it transited, and

could

follow the disk across. The central star in M57, the Ring Nebula,

flickered

in and out with the seeing conditions. The double-double (Epsilon

Lyrae)

was easily split, and diffraction rings were visible when the seeing

permitted.

Even a wheelchair-bound fellow club member was able to catch

views

of some objects (a shorter platform would have allowed him to see

nearly

all

of them), and my friends enjoyed sitting comfortably and observing.

For

public events, the intimidation factor is simply not there, compared to

large

Newts with ladders. One interesting phenomena is watching people

approach the scope; they walk over, staring at the secondary,

apparently suspended in midair! Once they get close enough they

can see the wires, and then marvel at how thin they are (0.015").

Here's a photo of the scope set up for

observing in the flatlands of Illinois, waiting for Jupiter to emerge

in the twilight. Not shown in this photo are the trap doors that

allow air to escape after being blown across the primary by the

fans. Note the Rigel Quickfinder on the mirror box - this is all

I need to find objects with a low-power eyepiece.

Ready for observing. Wish

those clouds would dissolve....

Setup and teardown require 15 and 10 minutes, respectively. All

components

of the telescope (including the equatorial platform) will fit behind

the back seat of my Subaru Outback,

along

with eyepiece cases and a tool box. Because of this, it gets used

a lot.

My conclusion is that this instrument

is a resounding success. Of

course,

my mind has already wandered to future scopes! An 18" or 20"

Cassegrain

is within reach, but it will require a faster primary (F/3.5 or less).

Such

a scope can still be extremely portable, and will have the same viewing

position

- feet planted on the ground. A thinner primary is a necessity

for

cooling and weight reasons.

In closing, I'd say that I am very happy with what I have learned in

the

construction of this telescope and its performance. I hope

that

in the future it inspires others to try the design, and shows that

Cassegrains

don't have to be inferior in terms of optical quality. If the

optics are top notch, then a scope with a well designed mechanical

structure will yield excellent images.

I'd like to thank all my friends for their

support and encouragement, my girlfriend for her understanding, John

Pratte for his help welding the tertiary support frame, Dick Wessling

for his advise regarding the optics and design, and Ed Jones for double

checking my calculations of the optical system.

Thanks for reading. Here's one last photo of the telescope and me

as daylight fades....

Photo

by John Stone

Build a Cassegrain! It's fun!

Mike Lockwood