30" F/3.8 Dobsonian, a.k.a. MBM

(Mike-Bob-Mike)

This summary is only the beginning of a big page that will have many

more pictures and many more details of the process, including some

video clips. The story of

the scope is just beginning, with the fall observing season coming

up. It will be great on deep sky objects, but I really can't wait

to stay up until the early morning hours and catch Saturn rising in the

east, and eventually mighty Jupiter.

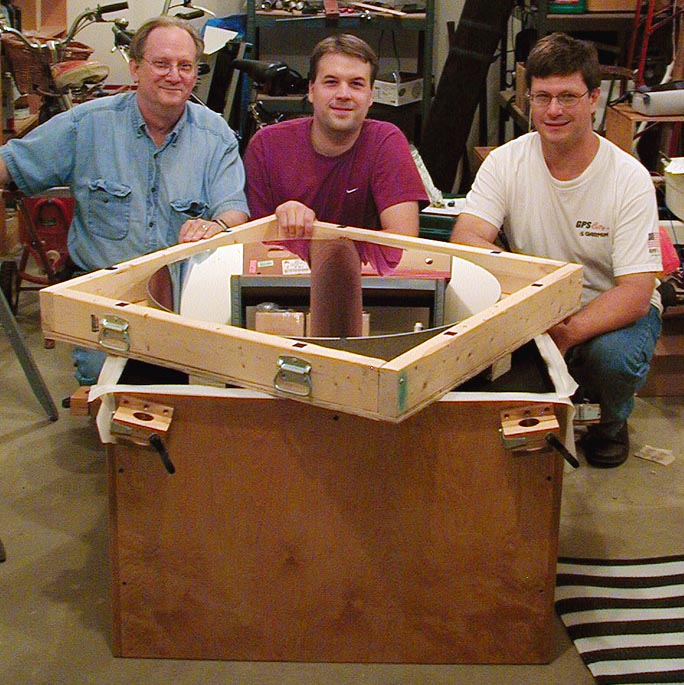

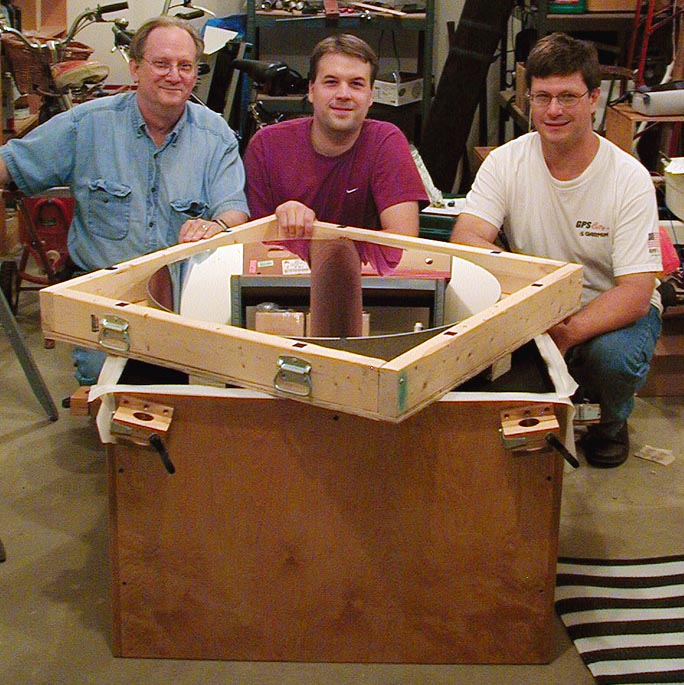

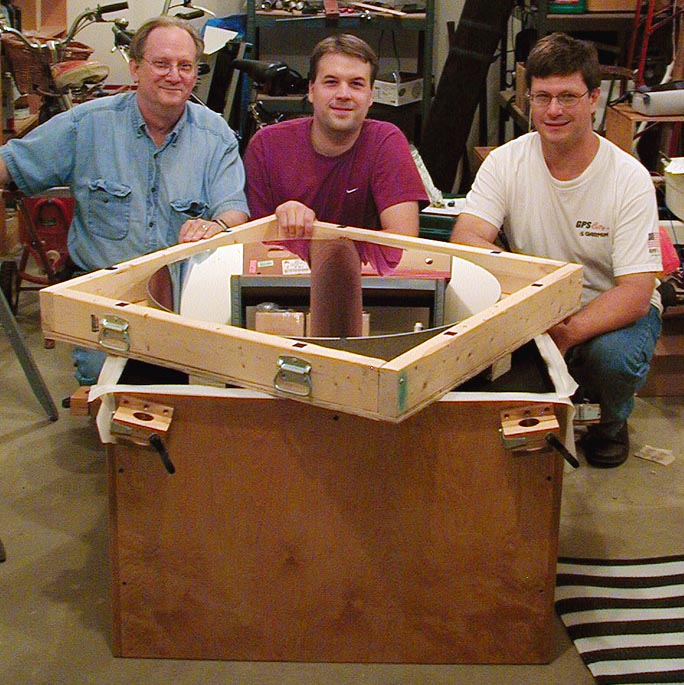

Here's a picture of (from left to right) Mike Conron, myself, and Bob

Nonnemann. The mirror sits in its transport box, on top of the

freshly painted mirror box.

A short summary of a very LONG process

This project started off last year (2003) when Mike Conron (a

mirror-maker and seasoned TM) and Bob

Nonnemann (a deep-sky junkie) decided (with the help of some beer) to

build a large telescope. After a bit of reasoning they decided on

an aperture of 30", and an order was placed for glass. The 2 1/8"

thick blank

was received 7 MONTHS later from Newport. (Note - Mike and Bob

own the scope, since

they bought all the parts.)

Mike C. took on the mirror grinding job (primary AND secondary), and

started modifying the

mirror grinding machine he had had for many years..

Bob took on mechanical construction, and started acquiring parts, such

as side bearings, mirror cell parts,

truss tubes and clamps, a focuser, and lots of baltic birch.

I heard about the project and volunteered to help with whatever I could

for the sheer

experience of it, (and so they'd call me when they went out observing).

Having made several F/4-ish mirrors before and having a knack for

figuring fast mirrors, I gravitated towards the mirror making

aspect. I had never worked with a machine, but Mike C. had used

his extensively, so I just observed for a while, watching him trek

through finer and finer grits. Mike C. improvised some clever

devices to make moving and lifting the mirror and the hydrostone tool

quite safe and easy. We proceeded through fine grinding into

polishing.

Mike C. made the 5.5" minor-axis diagonal

himself, including trepanning of the elliptical blank out of a 10"

Pyrex blank. This was done before he started working on the

mirror, while he was waiting for the blank to arrive. It was a

good use of time, and resulted in a fine looking diagonal.

About this time (late winter) Bob and I built the mirror box in my

basement in about

a day's time. I have a nice cabinet saw, so making precision cuts

is a

breeze. I used my biscuit jointer to add strength to the joints

and to align them. Bob stained and finished the box, with little

bits of help and advice from me. It looks great.

The mirror polishing hit a snag - Mike's machine had two

problems. First, we found out the turntable had warped, giving us

a huge case of astigmatism. Second, I found out that the 18"

polishing tool was wood, realized the problems this was causing and

would cause in the future, and I gave Mike 50 lbs. of Hydrostone which

he cast into a great 22" tool. With the turntable trued up with

plaster and duct tape (the mirror maker's secret weapon) and the tool

no longer flexing and warping, Mike tended the machine and slowly and

skillfully

polished out the blank and the remaining astigmatism. The final

polish was a beautiful thing to behold, and the knife edge images were

incredible.

I directed the figuring, and we began with the 22" lap, followed by a

16" lap (on a plaster disk used for my 16" F/4) using Mike C.'s

machine. After adding

significant correction the machine couldn't

perform the strokes we required, so I suggested we make a manual

overarm. Mike C. quickly crafted this from a 2x4 and some eye

bolts. We used the overarm with the 16" lap and hand-pushed it to

add

correction. It was tiring, but a huge amount of fun.

Finally, I finished the figuring with an 8" lap that I

had used on a previous mirror and had stored in the refrigerator for

several months. We ended up with a very smooth surface.

Testing in Mike's garage really makes quantifying the wavefront error

difficult due to temperature issues, but we're quite confident the

wavefront error is less than 1/4 wave P-V, and likely much less.

Bob and I assembled the secondary cage truss and mirror box and

balanced the tube assembly one very long day in late August. I

built the rocker box and turned it over to Bob about a week

later. He completed

the spider and secondary holder and diagonal cage assembly with a

little help from me.

On the evening of Sept. 7th, we removed the cardboard and cotton

covering from the

mirror, revealing the pristene coating for the first time. That

moment is immortalized in the picture above. The

polish is

wonderful, no scratches or pits that we know of. Champagne was

uncorked for

this occasion.

Final finishing and painting was left to Bob, and we reassembled

everything to try out the scope.

First light

First light occurred at approximately 8:30 pm on the evening of

Wednesday, September 15th, 2004. I aimed the scope at my best

guess for the location of M22, and found it after only a small

correction. Holding a 32mm Plossl inside the focuser (the truss

poles were slightly too long), I was able to achieve focus. It

was a very beautiful and satisfying sight. Nine months of work

were nearly complete. Here's a photo taken just after the event,

after I had to run off so as not to be late for another

appointment. By the time I got back, of course, it was raining,

and the scope was in the garage..

The following morning (Thursday) we made the necessary

modifications to the truss poles and rocker box to make the scope focus

properly and be able to point lower in elevation. We made a light

shield for the upper cage and did all the other stuff necessary to get

us ready for Astrofest 2004, which started that night!!! By 4pm

we were packed up and ready to leave. Here are a few photos of the completed scope

at Astrofest 2004.

Here's

a link to Mike Conron's excellent page on the 30" F/3.8 MBM scope.