More Information

Why purchase your mirrors from Lockwood Custom Optics?

Before we begin to answer this question, we want to say that yes, according to our testing and experience, there is a significant difference in optical quality and testing capability between suppliers. There, we said it. At LCO, we are not going to beat around the bush, and we are going to be honest with our clients.

The reason LCO has a good reputation and repeat clients is that optical sets from Lockwood Custom Optics simply outperform other optics when conditions allow. Often the differences are obvious, though sometimes great conditions are required to see it, and those great nights with superb seeing are exactly the time that you want optics that allow you to take advantage of those conditions.

-We have the most accurate and advanced test equipment in the amateur astronomy industry, and we take pride in using it properly and honestly.

-We have the most experience making fast optics and 24" and larger optics.

-We use only good quality glass that we have confidence in.

-Our products are priced lower than some competitors who have far less experience, and less advanced metrology and measurement techniques.

This means our slower mirrors and mirrors under 24" also benefit from our large/fast mirror experience and our testing methods, and they will provide you with the best images possible when conditions allow.

Our experience is extensive, and our Projects Page shows just a small sampling of the projects/optics that we have created or been involved with.

If you're considering another supplier, we suggest that you ask them how they test their mirrors, and specifically what hardware they use. We also suggest that you ask them how many mirrors they have made that are similar to what you have in mind. (This is particularly important for very large or fast mirrors.) You might get some very interesting answers.

We have worked hard to develop a test methodology that produces superb optics, we have continuously improved our process over time, and we have invested in modern metrology to measure our optics with the best accuracy in the industry.

Our process takes a lot of time, and this increases the cost of our products. However, it produces smooth, accurately corrected optics that don't show any astigmatism even when the substrate is quite thin.

It's

common to

see online questions about mirror quality and the price of that

quality. Mass-market, imported telescopes are so tempting at

their bargain-basement prices, and for some, these are the right

choice. However, for those who want the best substrate, accuracy,

coating, and support, it makes sense to spend a bit more. Quality

costs money, plain and simple, but in the end it saves time and trouble.

However,

we have also seen optical shops that charge significantly higher prices

than we do, while they have far less experience and practically no

investment in modern test equipment.

Over nearly 20 years of mirror making, founder Mike Lockwood has learned what is important in making a mirror and what details are most important. Here is a more detailed description of what we do, and why you may want to choose us as your optical supplier.

Quality glass is non-negotiable!

Let's start with the glass. To use an analogy, you wouldn't put a substandard, poorly-constructed foundation beneath an expensive, top-quality house. So, when LCO makes a mirror, we start with a quality piece of well-annealed glass. A properly annealed blank, properly machined so that it has very little wedge and is accurately round, will allow a high-precision shape to be polished into the glass, and it will hold that shape virtually forever if undamaged mechanically and chemically. As of late, such a piece of glass is not inexpensive.

A

poorly

annealed

blank may change shape over time, thus undoing the precision optical

work that was done on it. We find that most inexpensive import

telescopes use inexpensive, poorly-annealed glass. A mirror made

from such glass can also show a

significant amount of astigmatism or other upredictable distortion

while the mirror is cooling. Differences in temperature within

the

glass due to cooling cause temporary changes in the shape of the

glass. This is perfectly normal, but it puts temporary internal

stress

in the glass, which interacts unpredictably with the internal stress

left by a poor or non-existent anneal. This results in a

time-varying amount distortion

(often astigmatism) that is worst early in the night, but which often

never completely goes away. There is no cure for this behavior

unless

you completely re-anneal the glass and regrind, repolish, and refigure.

Most of the mirrors produced by LCO are made from monolithic (one piece) borosilicate glass, such as Pyrex or Supremax, or quartz, which are all fairly hard. Thus, it is more difficult to polish roughness into the optical surface, as often happens in large-volume production of inexpensive import mirrors using softer, less expensive, lower quality glass. (When it comes to glass, you do get what you pay for.)

Borosilicate will change shape temporarily as it cools. Softer, less expensive glasses such as plate or BK7 have a coefficient of thermal expansion that is several times higher than borosilicate, and they will change their shape by several times more than borosilicate. Quartz is of similar hardness to borosilicate, and is far more stable in its shape under cooling, having a coefficient of expansion that is roughly six times less than Pyrex. Naturally, it is significantly more expensive than borosilicate, and desirable as a substrate if one can afford it.

Again, when it comes to glass, you do get what you pay for.

However, this means that the cost of a high-quality, well-annealed, and nicely machined borosilicate mirror blank (just the raw machined and annealed glass) can be comparable to the cost of a finished mass-produced import mirror, or a significant percentage of what some cut-rate shops are offering optics for.

Thus, the quality of the glass is

one obvious reason for the difference in price between "premium" and

mass-produced mirrors. Any glass might have some internal bubbles

(which are of no concern for reflecting optics), but with a good anneal

it will not

change shape in strange ways as it cools, or more importantly, the

figure will not be at risk of changing over time

Thus, the quality of the glass is

one obvious reason for the difference in price between "premium" and

mass-produced mirrors. Any glass might have some internal bubbles

(which are of no concern for reflecting optics), but with a good anneal

it will not

change shape in strange ways as it cools, or more importantly, the

figure will not be at risk of changing over time

Additionally, LCO does not use substrates that are fused together from multiple pieces of glass. Slight variations in the properties of different pieces of glass and the risk of strange behavior and failure makes us leary of such substrates. If one fuse point fails, the mirror is basically ruined.

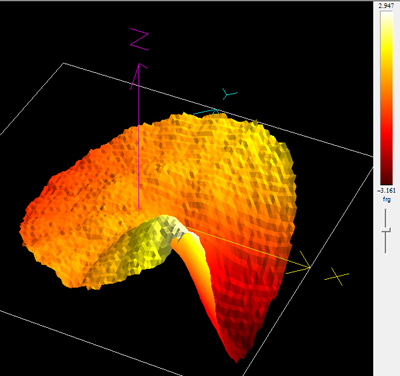

We have seen failure of such blanks this in the past. The image at right is the 3D profile of a mirror's surface after a fuse point failed, as measured with an interferometer. The peak-to-valley error is three waves, clearly resulting in a ruined mirror. We made a replacement mirror for this unfortunate client.

Therefore, we only work on single pieces of high quality glass, including

cast cellular substrates, which are one piece of glass cast in a mold

so that they have ribs and other structure. (See our Information

page for a photo of such a substrate.)

The

Process

With a

good

foundation to start on, we first grind

the back of the mirror for at least several hours, often more, in order to remove asymmetric shapes.

This ensures that it has a regular shape, that it will get uniform

support while on the turntable of a machine, and thus that

strange distortions will not be ground and polished into the front of

the mirror due to the shape on the back. A fine-ground mirror

back slides easily and with little friction on a

properly made mirror cell, and this means the cell can work properly

and support the mirror with little friction and thus lower distortion of its carefully-crafted shape.

Next, we grind and

thoroughly

polish the front surface. We

check the figure of revolution of the mirror and eliminate any

significant astigmatism, trefoil, or other distortions at this time.

Many opticians skip this step or use tests that have poor sensitivity

to these issues, and it is one reason why we have to take many mirrors

that we are refiguring back to a near-sphere. In that process, we

can make the mirror a good figure of revolution, a point from which it

can be figured.

This

testing is done with our 4D Technology PhaseCam 6000, a state of the

art interferometer capable of almost instantaneous phase shifting

measurement. LCO obtained this instrument to improve measurement

capability to achieve similar accuracy to the leading (and much

more expensive) optical shops in the world. No other optical shop

making telescope mirrors for the amateur market has anything close to

this measurement capability.

After a good figure of revolution is achieved and verified with our

modern metrology, we can then do the

figuring work that creates an extremely accurate parabolic shape on the

mirror. This work must be done patiently so that the surface is

kept smooth. Many fast-working opticians leave surface roughness,

and this will scatter light and degrade images. This is common in

lower-cost optics, and is another reason that you get what you pay for.

Also, the figuring must go right up

to the edge of the mirror without turning it.

For many cheap mirrors, the time available to produce them is limited,

so the outer zones are very nearly spherical, and the figuring work

never makes its way to those very important areas of the mirror.

This will degrade images later on when conditions are superb. In

contrast, we spend most of our time working on getting the shape of the

outer part of the mirror right, because this is critical to obtain the

best performance and images.

In fact, many mirrors that we have refigured have been fairly far

along

in figuring, but were left undercorrected in the outer zones, sometimes

to save time, and sometimes in a futile attempt to compensate for the

change in mirror shape that happens as a mirror cools off. This

means that we have

several days of work to do to fully correct the outer parts of the

mirror and finish off the rest of it to my standards. This

extra time and labor is partly why our prices are higher than other

vendors, but it is vital to get the best performance out of the optic.

Near the end of figuring, I

take many very careful readings as I tweak

the figure to the best accuracy that I can achieve without spending

obsessive amounts of time removing tiny defects that will never have an

effect on an image, even on the best of nights. Such obsession

would drive prices even higher and not produce any gain at the

eyepiece. Still, the final

tweaking can take days,

and this is another reason my prices are higher. However,

redundant testing at this phase ensures that most errors are caught

before the mirror is shipped for coating. With figuring

complete, I do a last check of the figure of revolution to make sure

nothing abnormal has popped up during the figuring process and produce

a final test report using the unparalleled 4D Phasecam system.

Near the end of figuring, I

take many very careful readings as I tweak

the figure to the best accuracy that I can achieve without spending

obsessive amounts of time removing tiny defects that will never have an

effect on an image, even on the best of nights. Such obsession

would drive prices even higher and not produce any gain at the

eyepiece. Still, the final

tweaking can take days,

and this is another reason my prices are higher. However,

redundant testing at this phase ensures that most errors are caught

before the mirror is shipped for coating. With figuring

complete, I do a last check of the figure of revolution to make sure

nothing abnormal has popped up during the figuring process and produce

a final test report using the unparalleled 4D Phasecam system.

With the

optical work complete, we clean the back and sides of the mirror, touch

up the bevel if necessary to eliminate any sharp edges and reduce the

risk of chipping if it were banged into part of a mirror cell or

something else. The last step for the glass (if it is not a

perforated primary) is to carefully and accurately center it on my

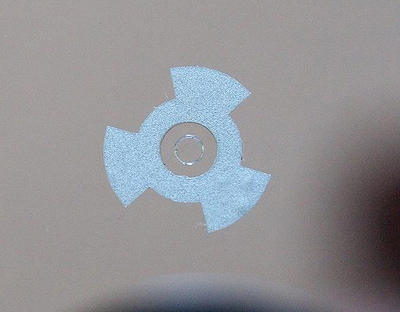

turntable and scribe

in small circles that are exactly centered on the mirror.

See the photo from one of my clients above at right.

These permanent, precision

markings

make it possible to apply a center spot very, very accurately

marking the center of the mirror. This allows very accurate collimation to be achieved with a good quality laser even for very fast

optical systems. In the image below at left the adhesive center

mark is very, very accurately centered.

Many

LCO clients use a Glatter laser and TuBLUG to collimate very fast

optics quickly and very accurately. Our center spot ensures that

this will work very, very well. Our clients spend less time

collimating and more time observing over the life of the telescope.

This saves significant time and improves image quality,

obviously, due to better collimation.

One might think that my job is done now, but it isn't. The final step for the optic itself is to receive a good quality coating, and I recommend coaters based on my experience working with 10+ coating companies over my career. I provide a clean mirror to the coater so that their work is as simple as possible.

Remember, you are responsible for the safety of your mirror during future recoating, so choose carefully, and please consult LCO before you send out your LCO mirror for recoating. It might save your mirror.

Test Reports

If you are looking for a test report that shows a perfect mirror, we suggest you look elsewhere. If you are looking for an honest report, you are in the right place.

Test reports are offered by some opticians, while others do not offer them. At LCO, for less aspheric mirrors, our 4D PhaseCam 6000 can produce a supremely accurate virtual null test. This means that many optics can be provided with a test report generated by the 4D system. Note that this is a test report produced with a professional interferometer, which is calibrated using 1/50-wave calibration spheres. This report may be done at additional cost due to the time involved, and it consists of hundreds of averaged tests.

If you are considering other sources for your mirror, consider this - a test report is just a piece of paper. It can be generated from many kinds of data, and that data may not necessarily come from an interferometer. Some terms or data might be disabled and not included in the final report. If you are unsure, ask the optician what instrument generated the data and report, ask what terms have been disabled, and ask how many measurements were done to create the report.

At LCO, we take steps to avoid including test stand distortion (due to gravity), but sometimes this is impossible. Our advanced metrology easily detects this distortion, but it is not always possible to remove it from the test data. Therefore, we find that our reports make an optic look slightly worse than we believe that it actually is, while we find that other optical reports often make a mirror look better than it actually is. We prefer pessimism.

Typically our reports are the result of averaging 100-200 measurements with different mirror rotations to remove test stand distortion while showing any astigmatism that is in the optic itself. While we have only just begun to offer this type of report, our calibrated instrument is showing consistent Strehl Ratios of 0.96 and higher for our finished optics that are within the aspheric null/measurement capability of our system. Again, we believe this is a worst-case measurement value, not a lucky single measurement.

Don't forget the Newtonian secondary!

In the past, the flat Newtonian secondary mirror was almost an afterthought. However, it is really half of the optical system. As optics become larger and faster, the size of these mirrors increases, and they become more difficult to make and more likely to have issues. For these reasons, LCO began testing secondary mirrors for Starmaster a decade ago, and eventually we began fixing them.

Currently, LCO requires that we provide the secondary mirror that will be used with out primary mirror. In the case we are refiguring a mirror or making a replacement mirror for an existing telescope, we require that we test any secondary mirror that is to be used with one of our primary mirrors. (Consider it a warning sign if someone tries to get you to use a secondary that we have not tested with your Lockwood primary mirror.) By doing this, we ensure that your entire optical system will perform superbly if the mirrors are supported properly.

We also assist clients with secondary mirror mounting issues, a service that no one else provides. This is one way that we "go beyond the process" of making a mirror, which leads to the next section......

Going

Beyond the Process

Finally, the last step in my process is to help the client get the most out of their optic.

This is what most people don't consider - the service during and after the sale. We want your mirror to perform as well as it can, because if it does not, it reflects poorly on us. I also want to share my experience. So, when you buy a mirror from LCO, in addition to quality optics, you also get LCO support in bringing your fan setup and mirror cell up to modern standards (if possible). This often happens while a telescope is being built.

We can often recommend changes or vendors that can help a client maximize the performance of their instrument, and these can make a significant difference in the performance of the mirror, the stability of collimation, and the equilibration of the mirror, all of which will add up to the best images that you can achieve with your instrument.

Additionally, we have advised many clients on observatory construction, telescope storage,

telescope equilibration, and other practical issues that need to be

addressed in order to achieve maximum performance and enjoyment with a

large telescope. This information comes from Mike Lockwood's experience using

large instruments and from things that he has learned traveling

domestically and internationally and visiting clients and other amateur

astronomers.

To summarize, the above

mentioned

steps are what make my optics, I believe, the best performing optic you

can get for your money. Mike Lockwood is an engineer by training,

and after over 20 years of building telescopes he understands the factors

involved in obtaining superb performance and shares his knowledge with

my clients.

So, if you want the best performance from your large telescope, we

believe that you should have optics mirror from LCO. With your purchase, you will also have support from Mike and have his

experience at your

disposal.

Important events and firsts as told by Mike Lockwood

Note: Many of the first/events described below are listed on my Projects Page.LCO was founded in 2006.

In 2007, I began making thin monolithic primary mirrors for Dream Telescopes. These were Pyrex, 16.5" in diameter, 1.25" thick, and at that time no one was making such thin mirrors commercially.

In early 2008, Dream switched to cast cellular blanks, so I bought the blanks and began making these mirrors for Starmaster Portable Telescopes. Thus was born the well-known 16.5" f/3.7. They proved to be a sensation in the visual telescope market. It was the first production visual instrument to combine high-quality, fast, and thin optics. This telescope allowed seated (comfortable!) observing all over the sky. More on these mirrors can be seen on this page. This was called the FX Series of Starmaster Telescopes.

Later in 2008, I made the first 20" f/3 mirror for visual use, an unheard-of 1.25"-thick, made from Pyrex. Five years later, I am still the only optician making such a mirror. Starmaster Portable Telescopes built the structure, and it is still my main visual instrument. I called it the 20" f/3 MX telescope, MX standing for "Mike's eXperiment". Three articles have been written about this instrument: First look at the Starmaster 20" f/3 MX, Observing with the 20" f/3 in Missouri, The 20" f/3 goes to Florida and WSP 2009, and it has been featured in columns in Astronomy Magazine and Sky and Telescope. In 2013, JPAstrocraft built a highly customized 20" f/3 for a client using my optics. (Update: In recent years, others have copied it, but I did it first and with the thinnest, fastest-cooling glass.)

With the availability of TeleVue Ethos eyepieces and later the Paracorr Type 2, telescopes at f/3.6 and faster could be enjoyed by all telescope buyers. (When the 20" f/3 was built, the eyepieces and correctors had not quite caught up to the drop in f/#.) With the Ethos and Paracorr Type 2, the 20" f/3 performed beyond my expectations. I quite literally forget that it is f/3.0 when I am using it. I installed a SIPS on it in early 2019 (discussed in WSP 2010 article) and this did away with Paracorr tuning, so I can just swap eyepieces at will and enjoy the views.

So, in early 2009, I made the first f/3.3 primary mirror for a commercial visual telescope, a 22" f/3.3. It was made from 1.4"-thick Pyrex. The telescope was built by Starmaster Portable Telescopes, and the f/3.3 telescopes were called the Super-FX series. Later in 2009, I produced a 30" f/3.3 for Starmaster, and the owner raved about its performance. Soon, other opticians were offering mirrors at f/3.3, but I did it first. 24" f/3.3 and 28" f/3.3 mirrors were also offered to fill in the range of sizes.

Also in 2009, I made a 14.5" f/2.55 mirror for an experimental visual instrument that I built. Visually it was a success, and is my favorite instrument for scanning the Milky Way that I have ever used. An article about it can be seen here.

In 2010, I moved to a new, larger shop. I chose to do this to allow work on larger, heavier mirrors, to reduce my lead time, and to increase my production and testing capability, all while maintaining the same high standards. In the middle of 2010, I produced the first 20" f/3.3 mirror from 1.25"-thick quartz. It was offered exclusively in a Starmaster telescope with a 4.5" quartz secondary mirror. This Starmaster model is called the Super-FX-Q, and is still sought after if you can find one for sale.

Also in 2010, in my shop, under controlled conditions, John Pratte (of JPAstrocraft) and I tested a multitude of mirror edge support schemes for John's 25" f/4 telescopes. We discovered that adding a roller to a whiffletree edge support prevented the support from pulling on the edge of the mirror, causing astigmatism. We have freely shared this discovery (see this article on mirror cells), and this type of edge support has since been implemented by several other manufacturers, at my urging. This has improved telescope performance markedly when the telescope is not pointed high in the sky. At LCO, we believe in helping manufacturers to support our mirrors in the best manner possible, and we support them in that endeavor whenever possible.

In 2011, I made a 28" f/2.75 mirror, another first. The telescope was built by Webster Telescopes, and the owner reported superb performance from an instrument that only needed one step at zenith!

From 2011 through 2013, I completed three 50" mirrors, two 42" mirrors, a 43.4" mirror, and two 40" f/3 mirrors.

At the beginning of 2014, LCO was incorporated and became Lockwood Custom Optics, Inc. I purchased a second Buccini MIC-1 interferometer and upgraded it to phase shifting capability (PSI), with analysis done by Durango from Diffraction International. PSI is the current industry standard, is a great improvement over static-fringe analysis, and allows very powerful analysis to be done on optics and optical systems. The other MIC-1 will be dedicated to high-precision flat testing in the future using the same software package. Additionally in 2014, an order was placed for a 32" f/2.8 to be built by Equatorial Platforms, and an article can be seen here.

A 45" f/3.75 mirror was completed in 2015, and a 40" f/3.75 Cervit primary was completed in late 2016 and had first light in early 2017.

A shop expansion is planned for mid-2017 in order to allow dedicated test setups to be constructed in a space where they can sit semi-permanently. This will also allow more space for generating and other optical work and general construction of equipment.

In 2018 we added a 4D Phasecam 6000 interferometer, a powerful instrument that improves our measurement capability and accuracy and allows other capabilities to be developed. This is the most advanced metrology in the amateur astronomy industry, and it allows us to provide test results for some clients in the amateur and professional realms.

Since that time we have completed a 40" Cassegrain system, and two 40" f/3.5 optics and associated large flats. We completed a 24" f/2.75 optic with test results provided. Other large mirrors are on order, and research continues in optical testing methodology.

Links

I describe Recent or Notable Projects here.

I list my Talks and Presentations here.

A link to my other Company Information Page is here.

My old (and not up to date!) amateur telescope making (ATM) site